Heavy Steel Structure Painting Line

HEAVY STEEL STRUCTURE PAINTING LINE

This system solves the problems of high labor intensity, low efficiency, large number of people, unstable coating quality, poor uniformity, and waste of paint that exist in manual spraying. It has the advantages of low labor force, high spraying efficiency, good spraying quality, uniform coating, and saving paint. It has achieved a balance between quality, quantity, and cost, and is an emerging product in the steel component painting industry. The device has an automatic scanning system that can intelligently identify the three-dimensional structure of components in all directions through 3D scanning, preparing for painting.

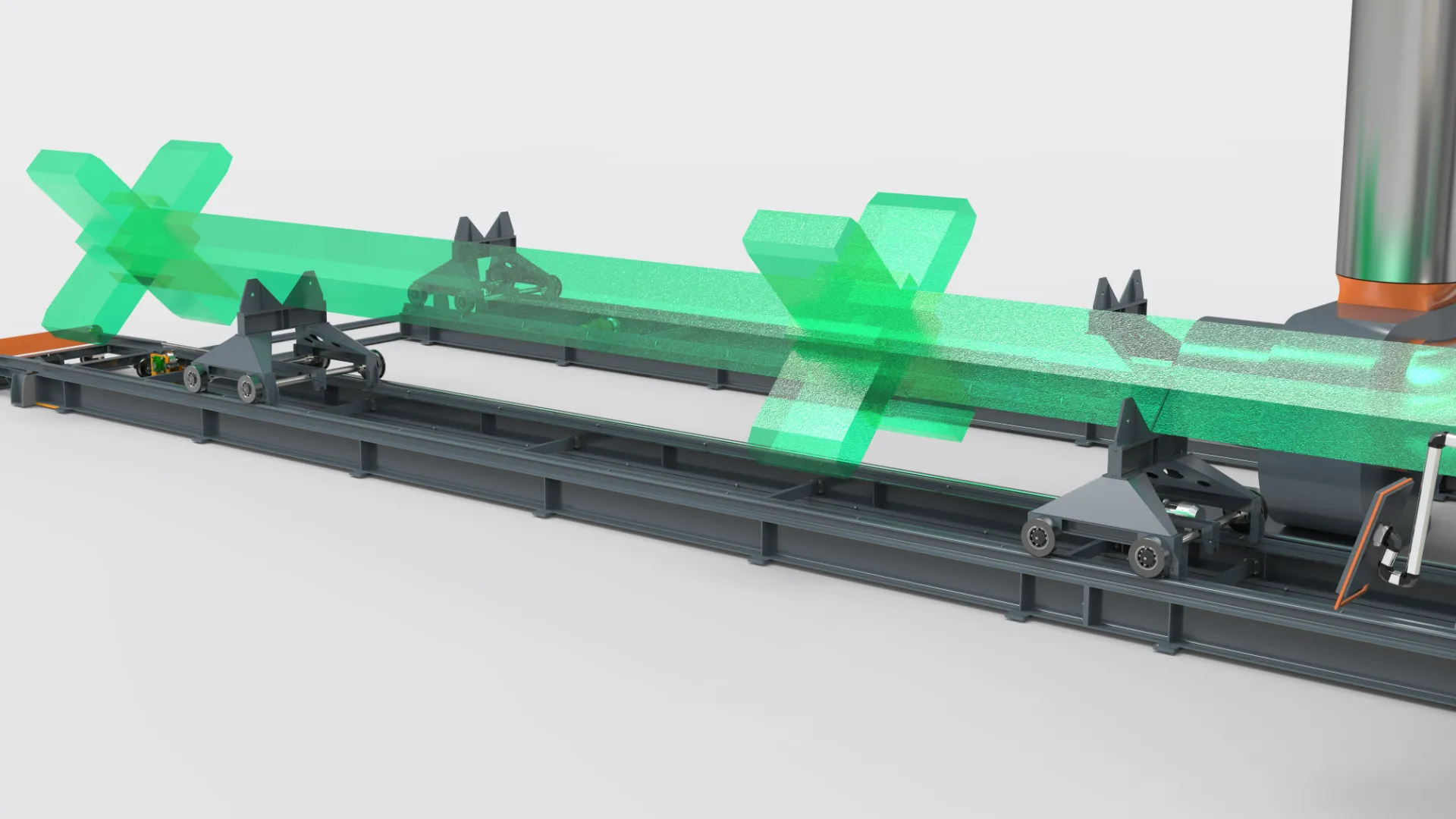

Equipped With Automatic Transportation and Turnaround Functions

Chain cars can transport heavy steel structural components along the track on their own, and after painting and unloading the components, they can return to their original position to continue transportation. The small car has various styles of load-bearing brackets, and different specifications of chain cars can be selected according to different types of components for transportation, meeting the diverse needs of heavy steel structural components.

Better Filtering Materials, Higher Filtering Efficiency

Built in nine grid spoiler and paint blocking cotton, adopting a two-stage filtration design for higher efficiency, and emitting gases that meet emission standards. Glass fiber paint blocking cotton, a dry filtering material developed specifically based on the characteristics of paint mist purification, is composed of multiple layers of glass fiber composite. Its density gradually increases with thickness and is supported by a layer of different materials. It has the characteristics of high efficiency, large capacity, low cost, and flame retardancy.

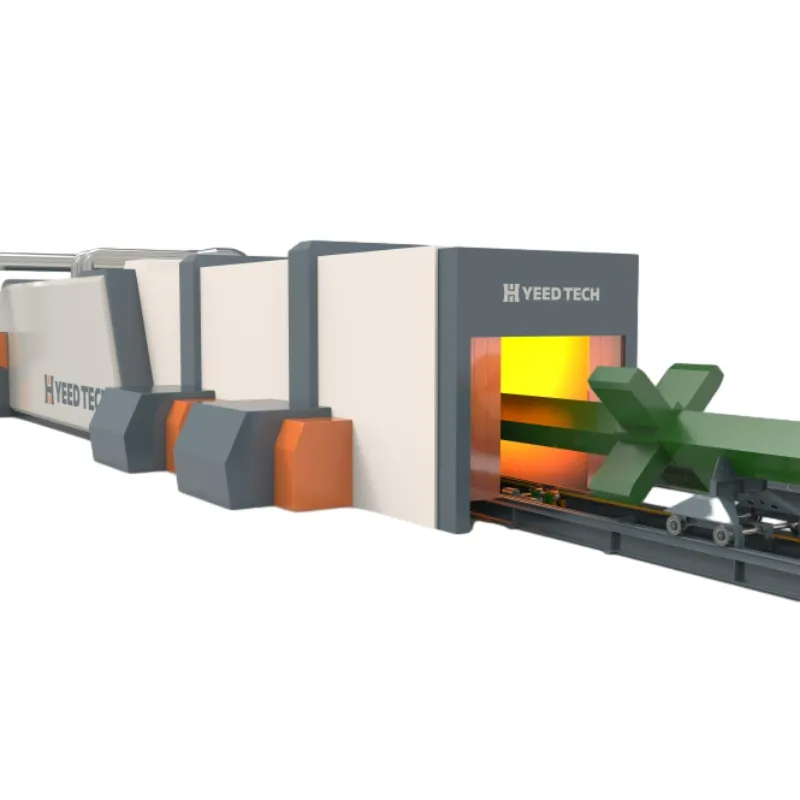

A Smarter Drying Solution That Saves You More

Drying is carried out using a natural gas combustion furnace, and the heated air is sent into the drying chamber through a pipeline by a fan. The output power of the electric furnace is automatically adjusted using an electric contact temperature sensor, thereby controlling the indoor temperature within the set temperature range of 40-80 ℃, accelerating the drying of the painted component surface. According to the climate and the properties of the coating, the indoor temperature can be adjusted to ensure that the components are in the drying room, achieving a surface drying effect with a single coating thickness of about 80um.

Latest news