Steel Structure Automatic Painting Line

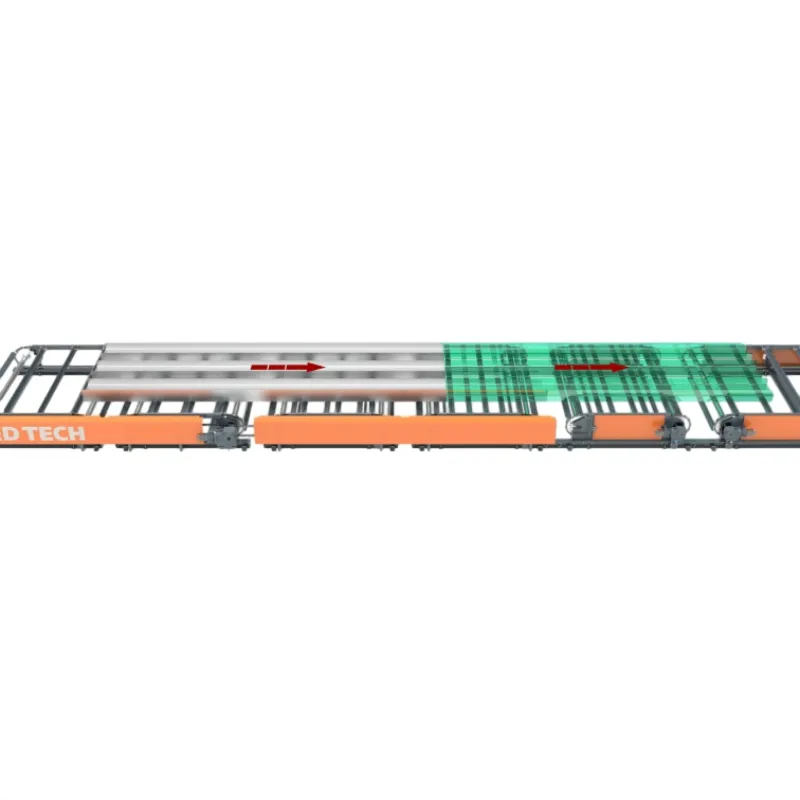

Equipped With a Fast Chasing Function

Adopting a chain T-shaped support design, the spacing between each support point is uniform and the contact points coincide. The component spraying process is unobstructed, reducing subsequent paint repair work. One click automatic operation of the equipment, intelligent adjustment of the travel distance between each batch of components, reducing spraying intervals, and improving work efficiency.

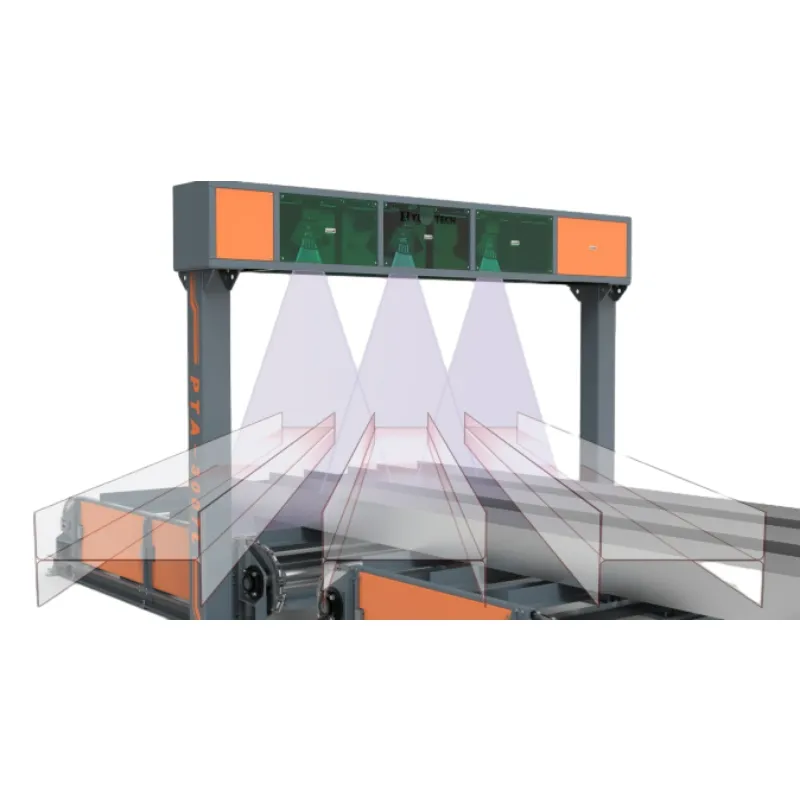

Intelligent Scanning of 3D Models of Steel Components

Perform comprehensive scanning of steel components, the recognition system automatically draws the shape pattern of steel components, and intelligently stops spraying on placement gaps, bolts, and brackets..

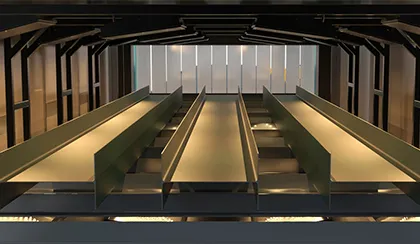

Natural Gas Catalytic Infrared Radiation Drying System

The drying system adopts a French Sunkiss Matherm infrared heating plate, where natural gas is mixed with air in a certain proportion and undergoes flameless combustion on the catalyst surface to avoid energy loss caused by visible light emitted by gas-phase combustion. It has advantages such as high efficiency, energy saving, environmental protection, and durability.

Longitudinal Conveying Device For Steel Components

The intelligent spray painting line for steel structural components is a fully automatic intelligent production line developed by our company for the spray painting of large steel components. This system solves the problems of high labor intensity, low efficiency, large number of people, unstable coating quality, poor uniformity, and waste of paint that exist in manual spraying. It has the advantages of low labor force, high spraying efficiency, good spraying quality, uniform coating, and saving paint. It has achieved a balance between quality, quantity, and cost, and is an emerging product in the steel component painting industry. The device has an automatic scanning system that can intelligently identify the three-dimensional structure of components in all directions through 3D scanning, preparing for painting.

Two sets of spray guns, each with six nozzles in different directions, can be automatically programmed based on scanning results to determine when and which nozzle needs to be turned on, making spraying more uniform and cost-effective.

The sprayed steel structural components enter the fast drying area for drying, and after the assembly line operation, they can meet the requirements for loading, saving space for stacking large components.

Because it is a reciprocating paint booth, paint mist and harmful gases can be more effectively treated, and the processing air volume is lower, saving environmental treatment costs for enterprises.

Latest news