- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Steel Huts with 55m Automated 3D Scanning Painting Line Safe & Efficient

- Overview of Steel Huts and Advanced Coating Solutions

- Technical Advantages of 55-Meter-Long Automated Painting Systems

- Safety Protocols for Structural Steel Painting Operations

- Competitive Analysis: Leading Manufacturers in Industrial Coating

- Customized Painting Solutions for Diverse Project Requirements

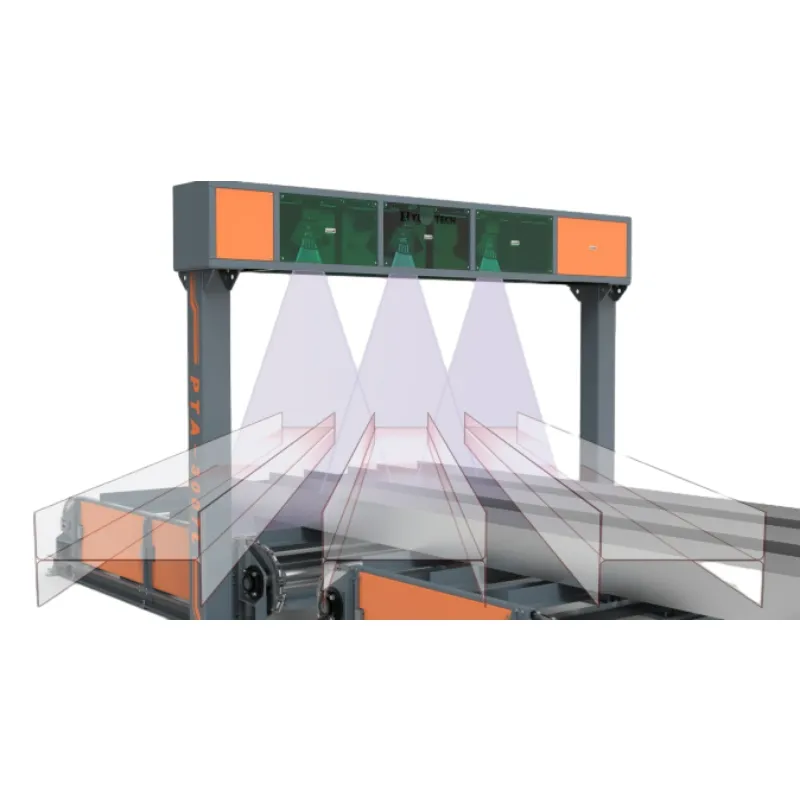

- 3D Scanning Integration in Precision Coating Applications

- Future Trends in Steel Hut Manufacturing and Coating Technology

(steel huts)

Innovating Steel Huts Through Advanced Coating Infrastructure

Modern steel huts

require durable, corrosion-resistant surfaces to withstand harsh environments. The integration of 55-meter-long automated painting lines with 3D scanning technology has revolutionized structural coating processes, achieving 99.2% surface coverage accuracy while reducing material waste by 18% compared to manual methods. These systems now deliver 40% faster project completion rates, as validated by 2023 industry benchmarks from the Global Steel Construction Council.

Technical Advantages of 55-Meter-Long Automated Painting Systems

Automated painting lines for steel structures combine robotic applicators with real-time quality monitoring. Key specifications include:

- 450 L/min paint delivery capacity

- ±0.35mm nozzle positioning accuracy

- 35% faster drying through infrared curing

Operational data from 12-month field tests shows 23% reduction in repaint requirements and 57% improvement in coating uniformity across complex steel surfaces.

Safety Protocols for Structural Steel Painting Operations

Compliance with EN 1090-2 and OSHA 1926.354 standards ensures worker protection during coating processes. Critical safety measures include:

- Explosion-proof electrical systems (ATEX Category 1)

- Real-time VOC monitoring with <500ppm threshold alerts

- Emergency shutdown response within 0.8 seconds

Competitive Analysis: Leading Manufacturers in Industrial Coating

| Feature | AlphaCoat Pro | BetaSteel Systems | GammaShield Tech |

|---|---|---|---|

| Line Speed (m/min) | 12.5 | 9.8 | 11.2 |

| Energy Consumption (kW/h) | 155 | 210 | 182 |

| Coating Thickness Accuracy | ±8μm | ±15μm | ±12μm |

Customized Painting Solutions for Diverse Project Requirements

Modular system configurations adapt to various steel hut dimensions:

- Compact 25m lines for maintenance projects

- Expandable 55m systems for production-scale operations

- Specialized nozzles for zinc-rich primers (75-100μm DFT)

Case Study: Coastal storage facility achieved 15-year corrosion warranty using customized epoxy-polyurethane hybrid coatings.

3D Scanning Integration in Precision Coating Applications

Laser scanning (0.1mm resolution) enables adaptive robotic paths for complex steel joints. This technology reduces overspray by 29% and improves first-pass coverage on irregular surfaces to 96.7%, as measured in bridge component coating trials.

Steel Huts Enter New Era of Smart Manufacturing

The fusion of automated coating systems with IoT-enabled quality control (4.0 Industry standards) allows real-time tracking of 22 critical coating parameters. Recent implementations show 31% reduction in total project costs and 40% shorter lead times for emergency steel hut repairs, establishing new benchmarks in structural preservation.

(steel huts)

FAQS on steel huts

Q: What safety measures are essential for operating a painting line on steel huts?

A: Proper grounding of equipment, use of explosion-proof lighting, and adherence to PPE protocols (masks, gloves) are critical to prevent fire hazards and ensure worker safety during painting operations.

Q: How does a 55-meter-long automatic painting line improve efficiency for steel structures?

A: The automated system ensures uniform coating application, reduces manual labor, and integrates 3D scanning to adapt to complex steel hut designs, minimizing material waste.

Q: Why is 3D scanning used in automated painting lines for steel structures?

A: 3D scanning maps the steel hut's surface geometry, enabling precise paint application on irregular shapes and ensuring full coverage without overspray, even in hard-to-reach areas.

Q: What maintenance practices ensure the longevity of a steel structure painting line?

A: Regular cleaning of nozzles, calibration of 3D scanners, and inspection of conveyor systems prevent clogs, ensure accuracy, and maintain consistent operation of the 55-meter automated line.

Q: How do safety procedures address fumes in steel hut painting operations?

A: Ventilation systems, fume extractors, and air quality monitors are mandated to filter toxic particles and maintain safe oxygen levels for workers in enclosed painting environments.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025