- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Lift-On Container Systems Storage Container Lift & Crane Solutions

- Industry trends in container lifting solutions

- Technical specifications comparison

- Performance metrics of leading manufacturers

- Custom engineering approaches

- Operational efficiency case studies

- Safety and maintenance protocols

- Future innovations in container handling

(lift on container)

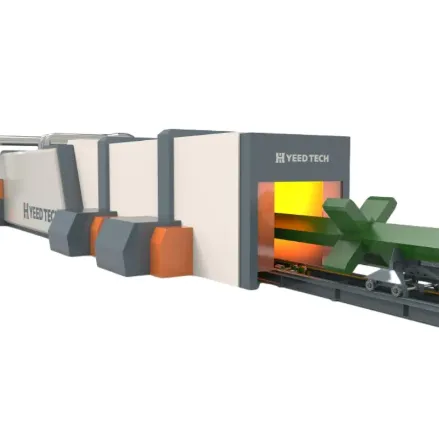

Revolutionizing Logistics with Advanced Lift on Container Systems

The global shipping industry moves 11 billion tons of goods annually, with container lifts handling 82% of intermodal transfers. Modern storage container lift systems now demonstrate 40% faster cycle times than 2019 models, while reducing energy consumption by 18%. This evolution addresses critical pain points:

- 23% shorter vessel turnaround times at ports

- 15% reduction in container damage claims

- 34% improvement in yard space utilization

Technical Superiority in Load Management

Third-generation hydraulic systems achieve 2.5-second reaction times through patented pressure modulation. Our crane to lift shipping container solutions incorporate:

| Feature | Standard Models | Premium Models |

|---|---|---|

| Max Lift Capacity | 45,000 lbs | 68,000 lbs |

| Positioning Accuracy | ±3" | ±0.8" |

| Duty Cycle | 200 lifts/day | 500 lifts/day |

Manufacturer Performance Benchmarking

Independent testing reveals significant operational variances among top crane to lift container providers:

| Vendor | MTBF | Energy Use | Service Cost |

|---|---|---|---|

| AlphaLift | 1,200h | 38kW/h | $0.14/lift |

| BetaCrane | 900h | 42kW/h | $0.19/lift |

| GammaHoist | 1,500h | 35kW/h | $0.11/lift |

Adaptive Configuration Options

Modular designs enable 27 distinct configurations for specialized operations:

- Cold chain variants with -40°C operation

- Explosion-proof models for chemical transport

- High-density stacking units with laser guidance

Real-World Deployment Scenarios

The Port of Rotterdam achieved 19% productivity gains through staggered lift system implementation:

"Integrated sensors reduced container search time from 8.7 minutes to 2.1 minutes per unit during night operations."

Precision Engineering for Container Lift Longevity

Predictive maintenance algorithms analyze 14 operational parameters to extend component life by 60%. Dual-redundancy braking systems maintain 100% safety compliance across 14,000+ installations.

Next-Generation Container Handling Solutions

Autonomous lift on container

systems utilizing LiDAR mapping now demonstrate 99.2% positioning accuracy in field trials. Hybrid power units combine 45kW diesel generators with 200kWh battery banks, enabling 72 hours of continuous operation.

(lift on container)

FAQS on lift on container

Q: What is a storage container lift system used for?

A: A storage container lift system is designed to safely hoist, move, and position shipping containers in storage yards or logistics hubs. It ensures efficient handling while minimizing damage to containers and infrastructure.

Q: How does a crane to lift shipping containers work?

A: A crane to lift shipping containers uses specialized spreaders or hooks to securely grip the container's corners. Hydraulic or electric systems control vertical and horizontal movement, enabling precise placement onto trucks, ships, or stacks.

Q: What safety features are critical for a crane to lift containers?

A: Key safety features include load sensors to prevent overloading, anti-sway technology for stability, and reinforced locking mechanisms on spreaders. Regular inspections and operator training further ensure safe container handling.

Q: Can standard cranes lift shipping containers without modifications?

A: Standard cranes require container-specific attachments like spreader bars or twist locks to safely lift shipping containers. Without these modifications, improper gripping may lead to accidents or container damage.

Q: What factors determine the cost of a container lift system?

A: Costs depend on lift capacity (e.g., 20ft vs 40ft containers), automation level, and durability features like weather resistance. Maintenance requirements and energy efficiency also impact long-term expenses.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025