- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Јан . 09, 2025 13:54

Back To List

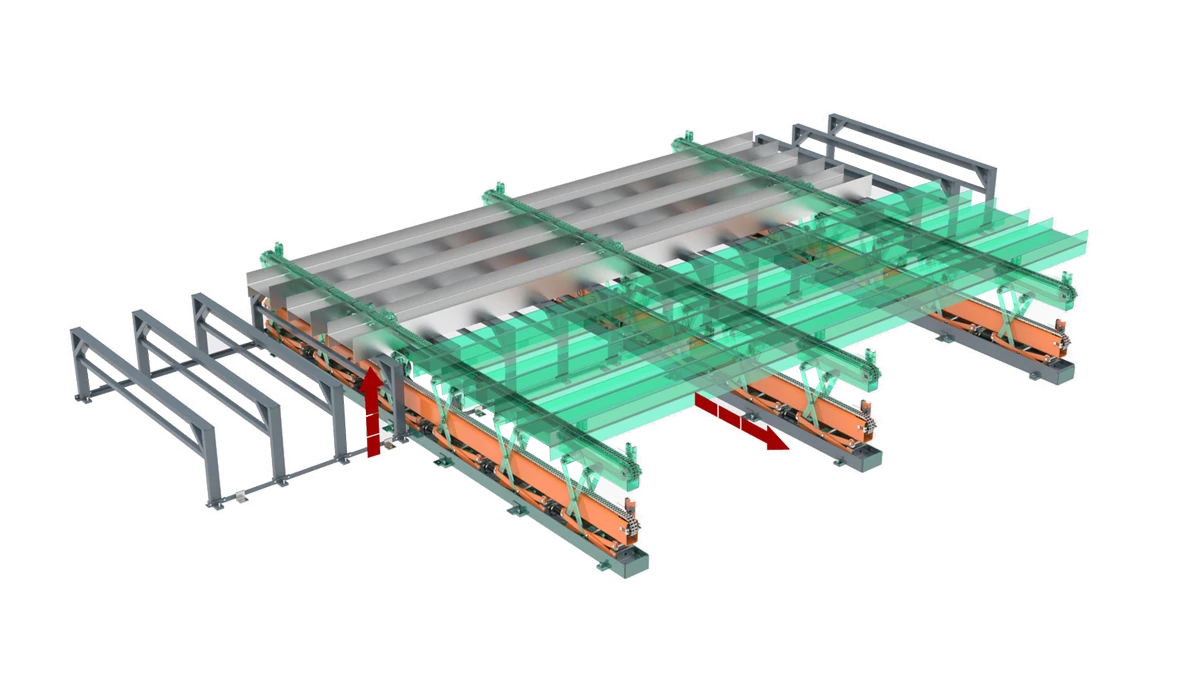

Steel Structure Automatic Painting Line

Venturing into the domain of advanced manufacturing, industries continuously seek innovations that significantly elevate efficiency, precision, and overall production value. Automatic spray coating machines have emerged as pivotal players in this evolution, offering unparalleled benefits to businesses across a swath of sectors.

Expert testimonies reinforce the notion that automatic spray coating machines are indispensable in today’s production landscapes. Industry experts underline the importance of integrating these machines in smart manufacturing facilities, emphasizing their role in facilitating seamless production flows and minimizing downtime. Technical advancements have allowed these machines to incorporate self-cleaning systems, further augmenting their utility by reducing the time and resources spent on maintenance. Authoritative sources in the manufacturing sector also highlight the adaptability of automatic spray coating machines. Their capacity to be programmed for varied product dimensions and complex surface geometries ensures that they remain relevant across diverse manufacturing needs. Additionally, industry conferences and journals provide ample evidence showcasing their pivotal role in enhancing product lifecycle management through improved surface protection and aesthetics. Trustworthiness, a crucial element for manufacturers when introducing new technologies, is paramount with automatic spray coating machines. These machines are built to comply with stringent industry standards, and their components are meticulously crafted to ensure longevity and durability. Leading manufacturers offer comprehensive training and support to facilitate smooth integration into existing production lines, ensuring a seamless transition and long-term reliability. In conclusion, the strategic deployment of automatic spray coating machines is not merely a technological upgrade but a decisive business move. They offer a compelling mix of precision, efficiency, and adaptability, firmly establishing themselves as essential assets for any forward-thinking manufacturing entity. Companies that effectively leverage these machines not only bolster their production capabilities but also reinforce their commitment to innovation, sustainability, and customer satisfaction, paving the way for sustained competitive advantage in a rapidly evolving industrial landscape.

Expert testimonies reinforce the notion that automatic spray coating machines are indispensable in today’s production landscapes. Industry experts underline the importance of integrating these machines in smart manufacturing facilities, emphasizing their role in facilitating seamless production flows and minimizing downtime. Technical advancements have allowed these machines to incorporate self-cleaning systems, further augmenting their utility by reducing the time and resources spent on maintenance. Authoritative sources in the manufacturing sector also highlight the adaptability of automatic spray coating machines. Their capacity to be programmed for varied product dimensions and complex surface geometries ensures that they remain relevant across diverse manufacturing needs. Additionally, industry conferences and journals provide ample evidence showcasing their pivotal role in enhancing product lifecycle management through improved surface protection and aesthetics. Trustworthiness, a crucial element for manufacturers when introducing new technologies, is paramount with automatic spray coating machines. These machines are built to comply with stringent industry standards, and their components are meticulously crafted to ensure longevity and durability. Leading manufacturers offer comprehensive training and support to facilitate smooth integration into existing production lines, ensuring a seamless transition and long-term reliability. In conclusion, the strategic deployment of automatic spray coating machines is not merely a technological upgrade but a decisive business move. They offer a compelling mix of precision, efficiency, and adaptability, firmly establishing themselves as essential assets for any forward-thinking manufacturing entity. Companies that effectively leverage these machines not only bolster their production capabilities but also reinforce their commitment to innovation, sustainability, and customer satisfaction, paving the way for sustained competitive advantage in a rapidly evolving industrial landscape.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025