Industry Overview: Trends & Development of Automatic Paint Spraying Machine

With rapid advancements in automated painting processes and the push for sustainable, high-precision manufacturing, the automatic paint spraying machine has become a critical asset across industries such as petrochemical, metallurgy, steel structures, water & wastewater, and automotive. Recent industry reports suggest the global industrial paint automation market is projected to reach $4.18 billion by 2027 (CAGR 6.8%).

- ✓ Key Trend: Integration of IoT & AI with spray systems for real-time accuracy and process optimization.

- ✓ Rising adoption for environmental compliance (low-VOC emissions, ISO 12944/ISO 9001 certified lines).

- ✓ Increasing demand for large-scale steel structure coating, driven by infrastructure and industrial expansions.

Innovative manufacturers continuously refine automatic paint spraying machine designs with modular configurations, closed-circuit recirculation, and precision-controlled nozzles — resulting in improved transfer efficiency and cost savings.

Technical Parameters Comparison: Automatic Paint Spraying Machine & Related Systems

| Model | Spray Output (L/min) | Air Pressure (bar) | Automation Grade | Applicable Industry | Control Mode |

|---|---|---|---|---|---|

| YEE-APS1000 | 0.8–2.5 | 3–6 | Fully Automatic | Steel, Petrochemical | PLC + HMI |

| MIG-SPRAY 950 | 0.5–1.8 | 2.5–5 | Semi-Auto | Automotive | PLC |

| AUTODISP-3500 | 2.0–3.0 | 3.5–7 | Automatic | Shipbuilding, Bridges | Microcontroller |

| YEE-SP SYSTEM | 1.2–2.8 | 4–6.3 | Fully Automatic | Steel Structure | PLC + Remote |

Note: For ISO/ANSI-certified production, high-precision control (±0.1bar air pressure regulation) and fine atomization (≤30μm droplet size) are prerequisites for achieving consistent film thickness and corrosion protection.

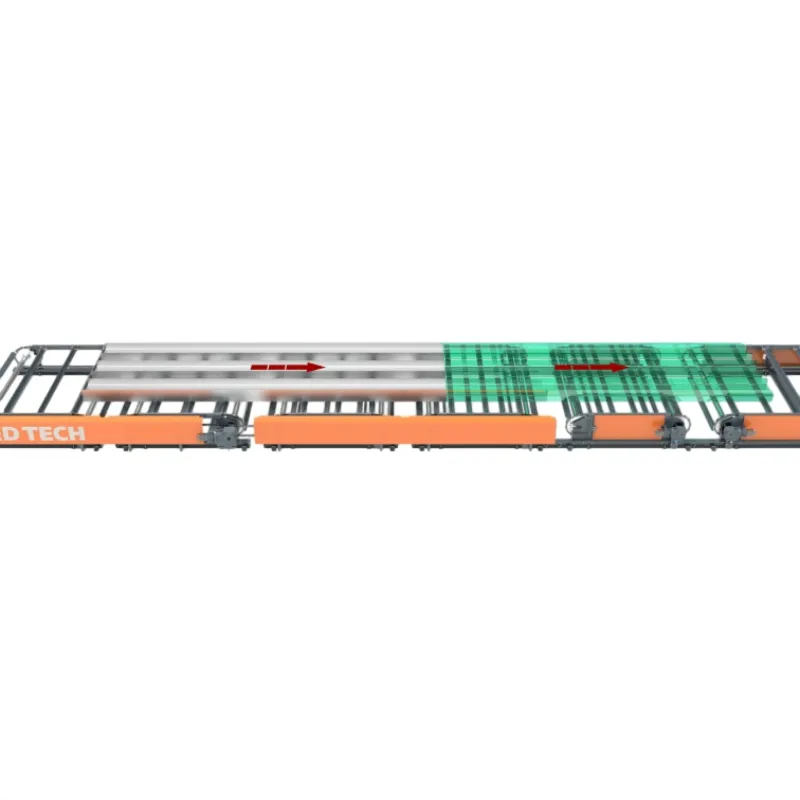

Steel Structure Automatic Painting Line: Process Flow & Technology Explanation

Key Manufacturing Technologies

- Material Handling: High-tensile steel chains, robust cast/forged conveyors, CNC-processed support modules for positional accuracy (±1mm).

- Paint Spraying: Atomization nozzles CNC-machined for uniform spray (drop size ≤30μm), self-cleaning structure to minimize clogging; Dual-pump recirculation for consistent feed.

- Surface Preparation: Blast wheels cast from chromium-molybdenum alloy (HRC57), compliant with ISO 8501/SSPC standards.

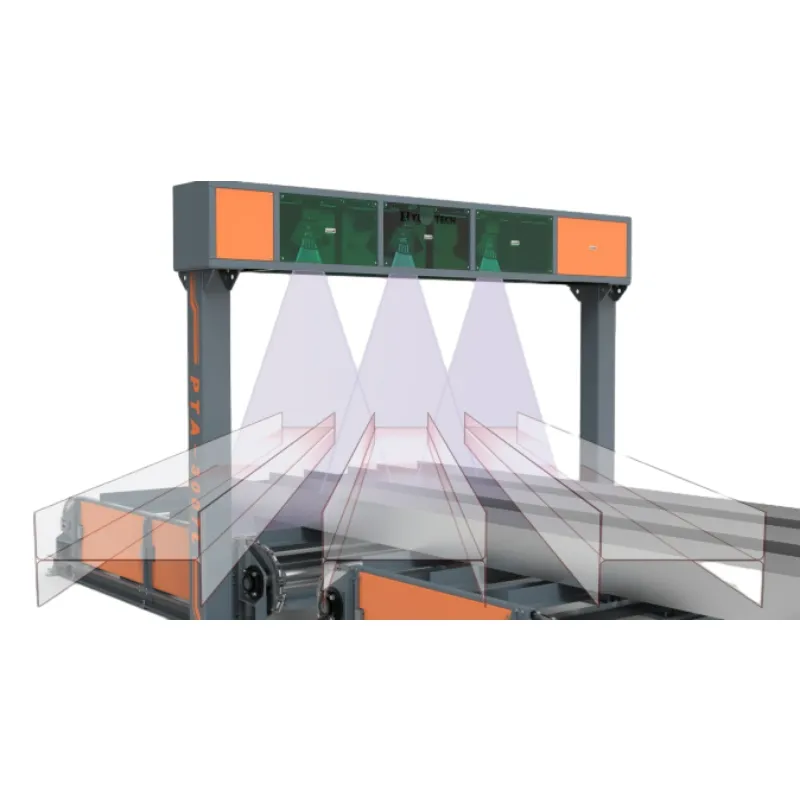

- Inspection: Automated film thickness gauges (ISO 2808 compliance); Optical sensors for surface uniformity inspection and data traceability.

- Control Systems: PLC (Siemens/Schneider), remote diagnostics, IoT interface for predictive maintenance.

Testing & Standards

- ISO 12944-5: Paint system for corrosion protection of steel structures.

- ANSI/NACE MR0175/ISO 8502: Surface and adhesion requirements.

- Longevity: Typical designed lifespan exceeds 15 years (verified by 3,000+ cycle salt spray testing, tensile tests).

Product Features & Customization — Steel Structure Automatic Painting Line

- Material: Mainframe Q345/ASTM A572, corrosion-resistant coating, load capacity 5–45 tons/line segment.

- Process: Heavy-duty welding + CNC-finishing; all bearings forged (ISO 9001 traceability).

- Control: Modular PLC (Siemens/Omron), touchscreen HMI, IoT-enabled diagnostics (remote and local monitoring).

- Spray System: Digital flowmeter control, self-clean nozzles, 360° multi-axis manipulators.

- Certification: CE, ISO 12944-5, ANSI, nationwide fire/environmental compliance.

- Customization: Color, chamber size, spray gun type, number of auto arms, and conveyor speed tailored per client needs.

| Item | YEEEED Steel Structure Painting Line |

|---|---|

| Max Workpiece Profile Length | 32 m |

| Spray Nozzle Quantity | 8 (customizable 4-20) |

| Throughput | Up to 15 t/h |

| Control Interface | PLC + 12” Touch HMI + Remote |

| Applicable Coating Types | Epoxy, Polyurethane, Zinc-rich, Waterborne |

Use Cases, Performance Data & Client Testimonials

- Petrochemical Plant (CNPC Project, 2023): Upgraded automatic paint spraying machine for offshore oil platform modules, achieving 38% higher paint transfer efficiency, average surface roughness Sa2.5 after blasting per ISO 8501, and 16% energy cost reduction.

- Large Span Bridge (Vietnam, 2022): Automated line handled 32-meter beams, coating output: 72,000 m²/month with film uniformity deviation <±7μm. Longevity validated by 3,000-hour salt spray test (ANSI/NACE compliant).

- Municipal Water Supply (EU, 2021): Automatic paint dispenser adapted for waterborne epoxy coatings, reduced VOC by 61% vs. manual spray, annual maintenance costs down by $41,000.

- [Haiyan Steel Fabricator]: “YEEEED’s fully automatic paint spraying system has reduced our labor costs and rejection rate, while consistently surpassing ISO quality metrics — excellent value for mid-large fabrication shops.”

- [EU EPC Contractor]: “In corrosion-critical pipeline projects, this line enabled us to achieve uniform high-build coatings with zero rework. Superb after-sales and fast spare part supply.”

Manufacturer Comparison: Automatic Spray Painting System Providers

| Brand | Country | Certifications | Key Features | Typical Delivery |

|---|---|---|---|---|

| YEEEED | China | ISO 9001, ISO 12944, CE | Steel structure focus, full customization, 24/7 support, advanced PLC/IoT | 55–70 days |

| Graco | USA | ISO 9001, UL | Industry-grade spray control, modular design, basic IoT integration | 90–120 days |

| Mitsuba | Japan | ISO, JIS | Pioneering powder & wet spraying, high safety, reliable but less flexible | 80–110 days |

| Sames Kremlin | France | ISO 14001/9001 | Precision pneumatic spray, eco-friendly, premium price segment | 105–150 days |

Professional FAQ: Automatic Paint Spraying Machine Technicalities

The system efficiently processes carbon steel, alloy steel, galvanized steel, and, with correct surface prep, stainless steel and aluminum; material properties must accommodate conveyor and blasting setups.

Compliant with ISO 9001 (quality), ISO 12944 (corrosion), ANSI/NACE, and optionally CE, JIS; delivered systems feature full third-party test documentation.

Through closed-loop feedback between digital flowmeter, atomization nozzle speeds, and optical thickness sensors (accuracy ±2μm), ensuring even coverage per ISO 2808.

Designed for >15-year operational lifetime; core components (PLC, pumps, drive motors) carry a 2-year warranty with local/remote tech support.

Industrial-grade compressed air at 0.7–1.0MPa (per ISO 8573-1) and three-phase power (380VAC/415VAC, 50/60Hz) are standard; backup frequency converters optional.

Yes, full support for OPC-UA/MQTT protocols, allowing MES / smart factory connection, remote monitoring, preventive maintenance scheduling, and ERP integration.

Standard lines: 55–70 working days from order to shipment; installation/commissioning: 7–12 days for mid-size system (on-site and remote commissioning supported).

Delivery, Warranty & Service Commitment

- Delivery: Standard 55–70 working days after deposit; fast-track possible for urgent projects (subject to schedule).

- Warranty: 2 years for all core equipment (PLC, pumps, bearings, drive motors); lifetime technical support for PLC/HMI program.

- After-Sales: Support by email, remote maintenance (VPN/IoT), and 24/7 phone assistance; local service partners in 8+ countries.

- QA/QC: All lines undergo full-load test with customer present, accompanied by ISO/CE/ANSI reports and video documentation.

Conclusion & Industry References

Cutting-edge advancements — from precision atomization to real-time data tracking, integrated automatic paint dispenser technology, and Industry 4.0 compatibility — deliver measurable value, quality assurance, and lifecycle cost savings.

In delivering robust anti-corrosion, high-throughput, and traceability, solutions like the Steel Structure Automatic Painting Line by YEEEED, benchmark the standards for safety, environmental stewardship, and productivity.

References: