- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Automatic Paint Spraying Machine: Precision & Speed Booster

Exploring technological advancements, industry applications, and performance breakthroughs

Industry Evolution and Technological Breakthroughs

The industrial coating sector has undergone radical transformation with the advent of automatic paint spraying machines. As manufacturing processes increasingly prioritize precision and efficiency, these systems have become indispensable in sectors ranging from automotive manufacturing to aerospace and heavy machinery. Modern automatic spray painting systems integrate robotic controls, precision atomization technology, and real-time monitoring to deliver unparalleled coating consistency.

The automatic paint spraying machine has evolved beyond simple automation to incorporate AI-powered vision systems that detect surface irregularities and adjust application parameters accordingly. This technological leap has been driven by three critical industry demands: reducing overspray (thereby lowering material costs), eliminating human exposure to hazardous environments, and achieving micron-perfect coating uniformity that surpasses manual application capabilities.

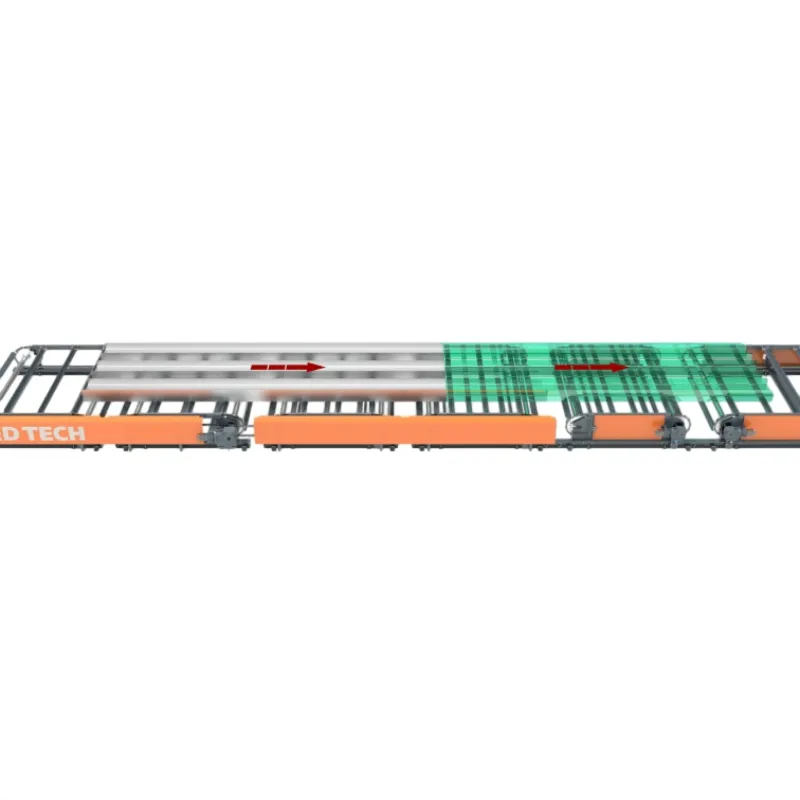

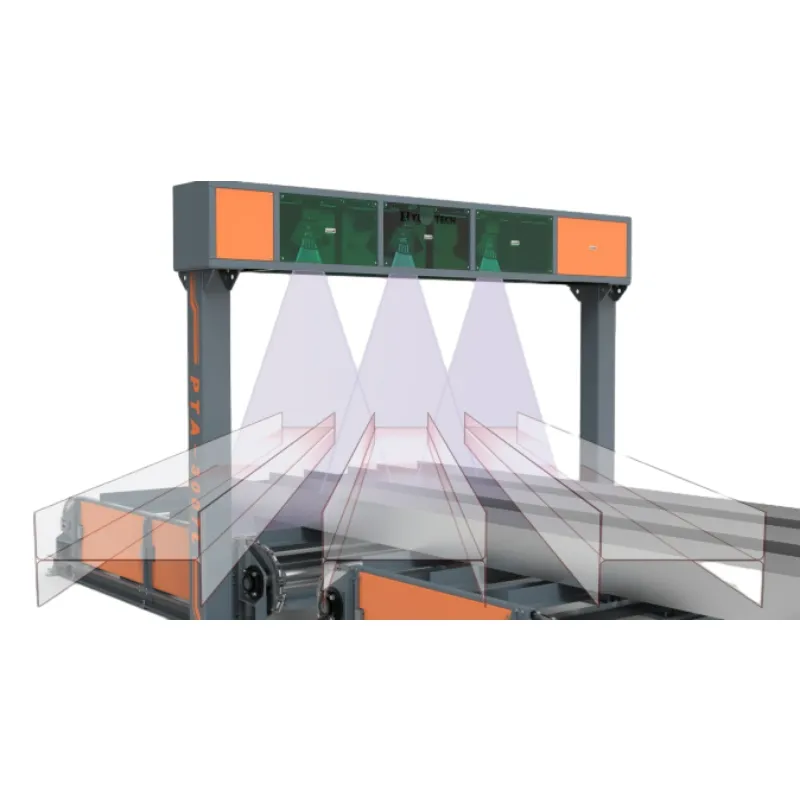

Cutting-Edge Product Spotlight: Steel Structure Automatic Painting Line

Steel Structure Automatic Painting Line

Manufactured by Yeed Tech Co.,Ltd., this advanced system represents the pinnacle of industrial coating technology. Its innovative design incorporates specialized safety features that prevent the lifting device chain from being impacted by structural components while ensuring secure transportation throughout the painting process.

Key technical innovations include:

- Scissor Lift Mechanism engineered with single-load capacity of 3.5T for heavy structural components

- Multi-stage safety detection systems enabling simultaneous spraying of multiple components

- Intelligent speed synchronization automatically adjusts conveyor velocity to match spraying operations

- Closed-loop overspray recovery system achieving 92% material utilization efficiency

Developed specifically for high-volume industrial applications, this automatic paint spraying machine dramatically reduces coating cycle times while maintaining exceptional finish quality across diverse structural geometries.

Request Technical SpecificationsTechnical Specifications Analysis

The performance parameters of modern automatic spray painting systems demonstrate remarkable improvements over previous generations. Throughput capacity has increased by 140% over the past decade while achieving 30% reduction in material waste. The following comparative analysis highlights key performance indicators:

| Performance Parameter | Entry-Level Systems | Mid-Range Systems | Industrial Grade (Yeed Tech) |

|---|---|---|---|

| Max. Coating Thickness | 70-100μm | 100-150μm | 60-300μm (adjustable) |

| Max. Component Size | 2m × 1.5m | 3.5m × 2.2m | 12m × 4.5m |

| Throughput Capacity | 15-20 units/hour | 25-35 units/hour | 60-80 units/hour |

| Positioning Accuracy | ±3mm | ±1.5mm | ±0.25mm |

| Material Utilization Rate | 65-75% | 75-85% | 89-94% |

| Power Consumption | 8-12 kW/h | 14-18 kW/h | 25-30 kW/h |

Performance Trend Analysis

Market Adoption Rate

Industry Applications & Process Integration

The implementation of automated painting processes has transformed manufacturing across seven core industries:

Structural Engineering

Bridge components and building frameworks require complete corrosion protection. Modern automatic paint spraying machines apply multi-layer coatings at precise micron-level thicknesses that meet ISO 12944 C5-M specifications for highly corrosive environments.

Automotive Manufacturing

Body panels receive consistent finishes through synchronized electrostatic application and infrared curing. The latest automatic spray painting systems achieve transfer efficiencies exceeding 85% while maintaining color consistency within ΔE

Industrial Equipment

Heavy machinery benefits from specialized formulations applied through programmable trajectory patterns. Complex geometries receive uniform coverage regardless of surface orientation thanks to 6-axis robotic manipulators and adaptive nozzle positioning.

Expert FAQ: Technical Considerations

Industrial automatic paint spraying machines must comply with ASTM D7091 (standard practice for nondestructive measurement of dry film thickness), ASTM D3359 (testing adhesion by tape test), and ASTM D823 (producing uniform films). Additionally, OSHA 1910.94 regulates ventilation requirements for spray finishing operations.

Advanced systems incorporate three-stage electrostatic charging (+60kV to +100kV), high-volume low-pressure (HVLP) nozzles with 0.5mm precision, and real-time gap detection that modulates flow rates. These technologies combine to achieve 93% material utilization rates.

Surfaces must achieve Sa 2.5 cleanliness per ISO 8501 with profile anchor patterns between 50-75μm. Automated abrasive blasting systems integrated with automated painting processes often provide optimal surface preparation with measurable consistency.

6-axis robotic arms with ±0.1mm repeatability maintain optimal nozzle distance (15-25cm) and perpendicular orientation (±5° deviation). Integrated 3D scanning creates digital twins for trajectory planning algorithms that calculate optimal pathing and speed profiles.

Advanced systems incorporate LEL (Lower Explosive Limit) monitoring, automated shutoff valves, class II division 1 electrical compliance, and emergency purge systems maintaining

Integrated viscometers continuously monitor material properties while temperature-controlled delivery systems maintain ±0.5°C stability. Automatic gun purging sequences between colors ensure zero cross-contamination.

Most installations demonstrate full ROI within 18-24 months through 40-60% labor reduction, 25-40% material savings, and 300-400% productivity gains compared to manual processes.

Technology Integration and Industry 4.0

The evolution of automatic paint spraying machines continues toward full digital integration within smart factories. Modern systems now feature:

- IoT connectivity with OPC UA and MQTT protocols for real-time monitoring

- Digital twin technology that simulates coating results before application

- Machine learning algorithms that optimize spray trajectories based on historical data

- Automated defect detection via hyperspectral imaging (400-1000nm wavelength analysis)

Industry References & Technical Publications

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025