- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

High-Efficiency Automatic Paint Spraying Machine for Precision Coating

Website: https://www.yeeeed.com

Mobile: +86 18103281106

Address: No.28, Wei’Er Road, Anping County, Hebei Province, China

Introduction: The Evolution of Automatic Paint Spraying Machine in Modern Manufacturing

The integration of automation into manufacturing processes has revolutionized various sectors over the last two decades. Among these, the automatic paint spraying machine has been pivotal in automating surface finishing, ensuring consistent quality, and enhancing productivity. As digital transformation advances, the adoption of automatic paint dispenser technologies and automatic spray painting system solutions has soared, reshaping industries like steel fabrication, automotive, furniture, and heavy equipment.

Explore Steel Structure Automatic Painting Line

Industry Trends: Driving Forces Behind Automatic Paint Spraying Machine Adoption

The market demand for automatic paint spraying machine systems is driven by the need for increased efficiency, environmental regulations, labor shortages, and demands for superior surface finish consistency. According to industry reports, the global automatic paint spraying equipment market is expected to register a CAGR of over 6.2% between 2023 and 2030 (MarketsandMarkets).

- Labor Efficiency: Automating the painting process reduces manual intervention, lowers workplace hazards, and boosts throughput.

- Consistent Quality: Automated painting ensures uniform film thickness and minimal defects.

- Environmental Compliance: Accurate paint dispensing reduces overspray and VOC emissions.

- Data-Driven Maintenance: Integration with Industry 4.0 provides predictive analytics for maintenance.

Product Spotlight: Steel Structure Automatic Painting Line by Yeed Tech Co.,Ltd.

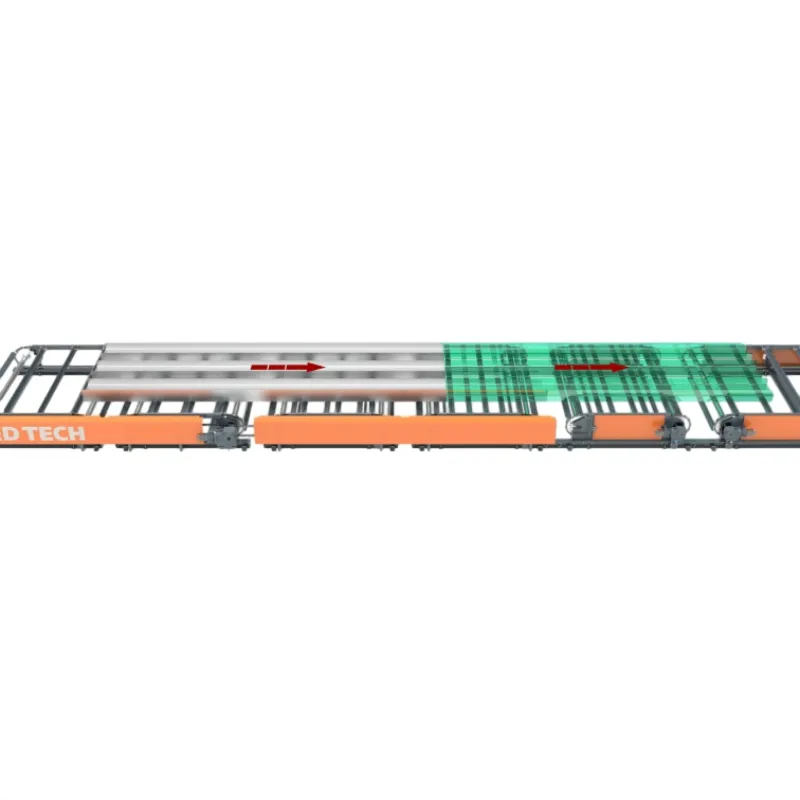

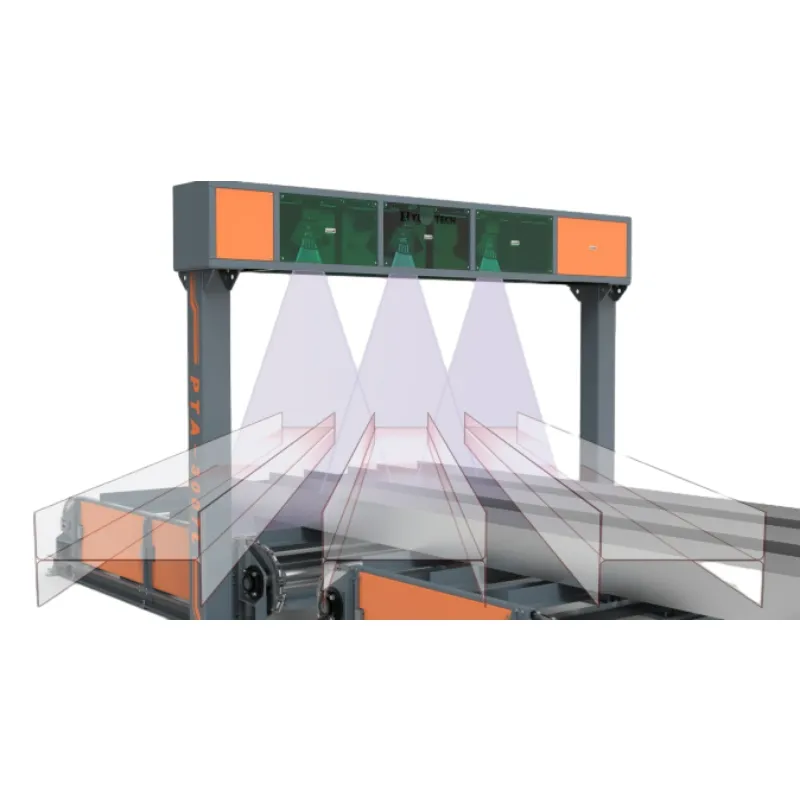

Yeed Tech Co.,Ltd. stands at the forefront of innovation with its automatic paint spraying machine solution: Steel Structure Automatic Painting Line. This state-of-the-art automatic spray painting system is engineered for large-scale steel structure applications, offering unprecedented safety, efficiency, and flexibility.

- Scissor Lift Design: Ensures a load capacity of up to 3.5T per component.

- Advanced Safety: Multiple safety sensors prevent chain collisions and guarantee safe component transport.

- Intelligent Adjustment: Automatic adjustment of conveying speed to synchronize with spray speed.

- Simultaneous Spraying: Efficient side-by-side component processing increases throughput dramatically.

- Application: Ideally suited for steel structures in civil engineering, bridges, high-rise buildings, and large fabrication shops.

Technical Parameters: Automatic Paint Spraying Machine Industry Benchmark

| Parameter | Typical Value | Remark |

|---|---|---|

| Maximum Load Capacity | 3,000–3,500 kg/component | Suitable for steel beams and heavy parts |

| Spray Gun Type | Airless, Air-assisted, Electrostatic | Application-optimized selection |

| Spraying Precision | ±0.1 mm | Consistent film deposition |

| Automation Level | Fully automatic | PLC & smart sensors integrated |

| Spray Width Range | 100–1500 mm | Customizable |

| Line Speed | 0.5–2.5 m/min | Auto-adjustable |

| Paint Type Support | Synthetic, Epoxy, Polyurethane | Broad compatibility |

| Safety Features | Multi-point sensors, Emergency stop | Comprehensive operator protection |

Technological Trends Visualization

Automatic Paint Spraying Machine: Typical Application Scenarios

- Civil and Infrastructure: Long-span bridges, viaducts, highway barriers

- Steel Building Fabrication: Warehouses, stadiums, and skyscraper frameworks

- Heavy Equipment: Ship hulls, mining machinery, wind power components

- Automotive & Transport: Truck chassis, subframes, public transport vehicle parts

- Energy Sector: Pipelines, transmission towers, oil storage tanks

- OEM Manufacturing: Contract painting services for hardware and large assemblies

Expert Q&A: Understanding Key Concepts in Automatic Paint Spraying Machine Systems

-

Q1: What is the core material used in the Steel Structure Automatic Painting Line?

A1: The main structural frame is constructed from high-strength carbon steel, providing durability and excellent load-bearing properties crucial for industrial use. -

Q2: What specifications of automatic paint dispenser systems are integrated?

A2: The line employs precision-controlled dispensers capable of delivering 30–120 ml/sec, supporting viscosity ranges from 20 to 110 sec (Ford cup #4). -

Q3: Are there standardized installation and commissioning processes?

A3: Yes, installation follows GB/T 5226.1-2019 (China Machinery Safety Standard) and international ISO 12100 guidelines for industrial machinery safety. -

Q4: What is the flexibility of the automatic spray painting system in handling component sizes?

A4: The system accommodates parts up to 12 meters long, 2.2 meters wide, and supports simultaneous side-by-side painting of multiple units. -

Q5: How do safety interlocks function?

A5: Sensor-based monitoring halts the system if abnormal vibration, chain deviation, or unauthorized access is detected, ensuring strict operator safety. -

Q6: Is it compatible with environment-friendly paints?

A6: Yeed Tech’s line can process both solvent-based and waterborne paints, promoted as per industry environmental standards. -

Q7: How is maintenance downtime minimized?

A7: Real-time diagnostics and modular design allow for predictive maintenance, reducing unscheduled downtime to less than 1.5% of annual operational hours.

Why Choose Yeed Tech Co.,Ltd. for Your Automatic Paint Spraying Machine Solutions?

- Proven Expertise: Over 15 years in automated painting process and industrial finishing solutions.

- Direct Manufacturer: End-to-end control ensures quality, customization, and prompt technical support.

- Comprehensive Support: From line design, onsite installation, to long-term maintenance and upgrades.

- Commitment to Innovation: Continuously investing in R&D for smarter, greener, and more efficient surface finishing technologies.

- Global Reputation: Projects executed in 37+ countries, in compliance with CE, ISO, and global safety norms.

To discuss your automatic spray painting system requirements or request a tailored solution, contact Yeed Tech Co.,Ltd. by phone: +86 181 0328 1106 or email: yeed@yeed-tech.com.

Conclusion

The deployment of automatic paint spraying machine technologies represents a paradigm shift towards cost-effective, high-throughput, and environmentally responsible surface finishing. As industries embrace digitalization, the synergy of automatic paint dispenser precision, automated painting process efficiency, and robust automatic spray painting system safety will increasingly define the leaders in this sector.

Steel Structure Automatic Painting Line by Yeed Tech Co.,Ltd. stands ready as a benchmark of quality, reliability, and smart engineering for global manufacturers.

- “Recent Trends in Automated Surface Finishing Technology”, Journal of Coatings Technology and Research (SpringerLink)

- “Smart Manufacturing and the Role of Automated Paint Systems”, SME Connect (sme.org)

- Industry insights and technical FAQ, Finishing.com – World Surface Finishing Forum

- “Spray Painting Robot Market — Growth, Trends, COVID-19 Impact”, MarketsandMarkets (marketsandmarkets.com)

For further in-depth industry best practices and solutions, visit the Yeed Tech Co.,Ltd. website.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025