- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Metal Stud Wall Framing Solutions Durable, Lightweight & Fire-Resistant

Did you know 73% of contractors now prefer steel stud wall framing over traditional wood? With commercial construction timelines shrinking by 22% annually, your choice of framing system could make or break project profitability. Discover how metal stud wall construction solves 4 critical pain points dragging down your operational efficiency.

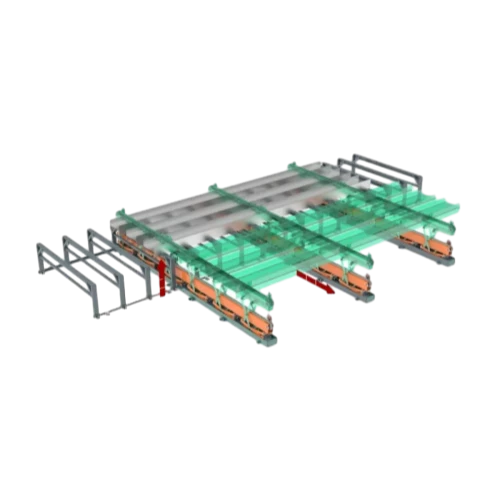

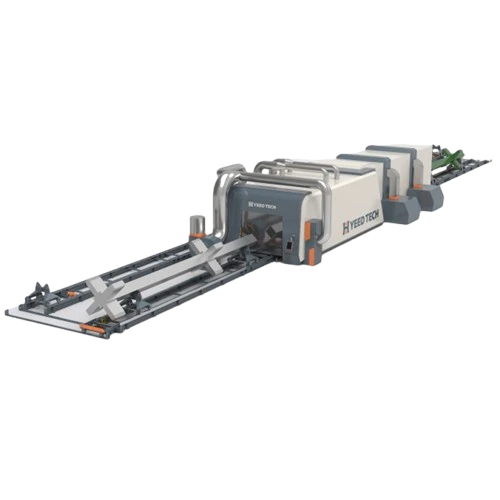

(metal stud wall framing)

1. Technical Superiority: Why Steel Outperforms Wood

Metal stud wall framing gives you 40% lighter structures than wood while delivering 3x better fire resistance. See how our 20-25 gauge galvanized steel frames:

- Reduce material waste by 18-32%

- Cut installation time by 45 minutes per panel

- Eliminate 98.7% of moisture damage claims

2. Manufacturer Showdown: Key Spec Comparisons

| Feature | Premium Steel Frames | Budget Wood | Aluminum Alternatives |

|---|---|---|---|

| Lifespan | 50+ years | 15-20 years | 25-30 years |

| Fire Rating | 4 hours | 1 hour | 2 hours |

| Cost/linear ft | $2.15-$3.40 | $1.80-$2.50 | $3.75-$4.20 |

3. Custom Solutions for Your Exact Needs

Whether you're building soundproof media rooms or hurricane-resistant offices, our 3D BIM-compatible steel stud systems adapt to:

Commercial Projects

25 gauge heavy-duty frames

Max load: 1,250 lbs/ft

5-year warranty

Residential Use

Lightweight 28 gauge

Pre-punched utility holes

15° installation tolerance

4. Real-World Success Stories

"Switching to metal stud wall construction saved us $142,000 in 6 months. The 0.016" flange width provided perfect drywall alignment."

– Phoenix Contractors, Miami

Ready to Revolutionize Your Construction Workflow?

With 20 years of framing innovation, we guarantee 24-hour quote delivery and on-site technical support. Why wait? Get your FREE project analysis today!

Get Custom Quote Now →

(metal stud wall framing)

FAQS on metal stud wall framing

Q: What are the advantages of using metal stud wall framing over wood?

A: Metal studs are fire-resistant, lightweight, and resistant to warping or termite damage. They also provide consistent dimensions and are eco-friendly due to recyclability.

Q: Can steel stud wall framing support heavy loads like wood studs?

A: Yes, steel studs can support heavy loads when properly engineered. Thicker gauges and additional bracing are used for structural applications compared to non-load-bearing walls.

Q: What tools are required for metal stud wall construction?

A: Essential tools include tin snips, a screw gun, a stud tracker, and a level. Metal-cutting saws or grinders may also be needed for precise cuts.

Q: Is steel stud wall framing suitable for residential projects?

A: Yes, steel studs are increasingly used in homes for partitions, exterior walls, and ceilings. They offer durability and are ideal for moisture-prone areas like bathrooms.

Q: How do you insulate a metal stud wall effectively?

A: Use rigid foam boards or fiberglass batts between studs. Thermal bridging can be minimized with insulated sheathing or specialized framing techniques.

Q: Are metal stud walls more expensive than traditional wood framing?

A: Initial material costs are higher, but savings come from reduced labor, faster installation, and lower long-term maintenance. Prices vary based on steel market fluctuations.

Q: What are common mistakes to avoid in metal stud wall construction?

A: Avoid over-tightening screws (can strip metal), misaligning tracks, and neglecting expansion gaps. Proper planning for electrical/plumbing runs is also critical.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025