- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

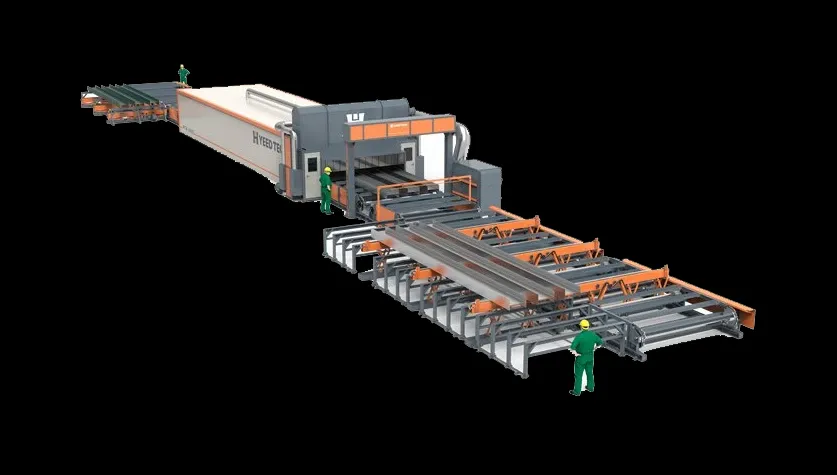

Boost Industrial Finishing with Advanced Spray Automation

In the rapidly evolving world of manufacturing, precision, consistency, and speed have become critical for maintaining quality and staying ahead of the competition. One of the most transformative innovations in this field is the automatische spuitlijn—a solution that streamlines production while ensuring impeccable surface finishes. These systems are designed to meet the high standards of modern industries, from automotive and electronics to furniture and metal fabrication, delivering uniform coatings with minimal human intervention and maximum efficiency.

Boosting Efficiency with Automatic Spray Painting Solutions

Incorporating automatisch spuiten technology into your production line means saying goodbye to uneven finishes, paint waste, and slow throughput. These systems are engineered to deliver consistent, high-quality paint application on every part, regardless of size or shape. Whether you're dealing with high-volume orders or custom batches, automatisch spuiten ensures each product meets exacting aesthetic and functional standards. By automating the process, you can also reduce exposure to fumes and overspray, improving workplace safety while enhancing productivity.

Precision Control through Automatic Spray Paint Technology

De kracht van automatische spuitverf systems lies in their ability to replicate precise painting motions with robotic accuracy. With programmable patterns, adjustable pressure, and intelligent sensors, these systems adapt effortlessly to complex surfaces and multiple coating layers. This level of automation minimizes material usage, reduces defects, and shortens drying times—factors that collectively lower operational costs and increase output. Investing in automatische spuitverf technology is not just about painting, it’s about optimizing your entire finishing process.

How Paint Consistency Affects Final Product Quality

With automatische spuitverf, you ensure that each application is smooth, uniform, and perfectly measured, which directly impacts the durability and visual appeal of the final product. In industries where surface quality is a selling point, such consistency makes a measurable difference.

Controlled Environments with Automatic Spray Paint Booths

For operations that demand a clean, dust-free environment, the automatische spuitcabine is a vital component. These enclosed chambers are designed to filter air, control humidity and temperature, and manage overspray. The automatische spuitcabine not only protects your products during application but also safeguards the health of your operators by maintaining air quality standards. With programmable settings and integrated ventilation systems, these booths are ideal for applying primers, base coats, and topcoats in both solvent-based and water-based applications.

Streamlined Performance from Automatic Paint Spray Machines

De automatic paint spray machine acts as the mechanical heart of your coating system, delivering high-speed, high-accuracy performance across countless applications. Whether mounted on a robotic arm or fixed on a track, this machine offers unmatched flexibility and power. With options for electrostatic, HVLP, or airless spraying, the automatic paint spray machine meets the specific needs of your materials and production speed. It simplifies complex jobs, from intricate panel work to large-scale industrial components, ensuring you achieve professional-grade finishes every time.

Versatility Across Industries and Materials

From automotive panels and plastic components to wooden furniture and metal assemblies, the automatic paint spray machine adapts to a variety of surface materials and shapes. Its customizable settings and nozzle configurations make it a favorite in multi-product lines

Automatic Spraying Line FAQs

Q: What is the main benefit of an automatic spraying line?

A: An automatische spuitlijn significantly enhances productivity, consistency, and quality control while reducing manual labor and material waste.

Q: How does automatic spray painting improve finish quality?

A: Automatic spray painting provides precise control over application thickness and pattern, resulting in a flawless, even finish across all surfaces.

Q: Is automatic spray paint suitable for complex geometries?

A: Yes, automatische spuitverf systems are designed to handle complex shapes and varying part sizes through programmable movements and adaptive technologies.

Q: What makes an automatic spray paint booth essential?

A: A automatische spuitcabine ensures a controlled environment for dust-free, high-quality finishes while protecting workers from hazardous fumes.

Q: Can one machine handle multiple types of coatings?

A: Absolutely. The automatic paint spray machine is compatible with various paints and coatings, including primers, lacquers, and enamels, making it ideal for diverse production needs.

Producten Categorieën

Laatste nieuws

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NieuwsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NieuwsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NieuwsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NieuwsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NieuwsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NieuwsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NieuwsMay.28,2025