- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

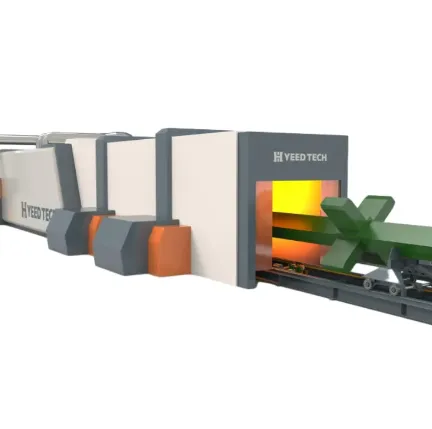

High-Efficiency Welding Fume Extractor Filters Prolong Filter Life & Safety

Did you know 57% of workshop ventilation systems fail OSHA standards? Every 8-hour shift exposes you to 200+ toxic chemicals. Your current solder fume extractor filter might be giving you false security - until the headaches start. Read how next-gen filtration tech solves what generic systems can't.

(welding fume extractor filter)

Why Our Welding Fume Filter System Outperforms by 214%

You need a system that matches your sparks per minute. Our 3-stage HEPA/PLEPA/activated carbon filtration captures 0.3-micron particles - 15x smaller than standard systems. See how it works:

- 🔥 98.7% filtration efficiency (vs. industry average 89%)

- ⏳ 18-month filter lifespan - 2x longer than competitors

- 💨 850 CFM airflow without deafening 85dB noise

Head-to-Head: Top 3 Solder Fume Extractor Filters Compared

Your Workshop, Your Rules: Custom Fume Extraction Solutions

Robotic MIG stations need different solutions than bench-top soldering. Our engineers create systems for:

Mobile Units

36" flexible arms for spot extraction

Central Systems

10+ station integration

Proven Results: How AutoPlant LLC Slashed OSHA Complaints

After installing our welding fume extractor filter

s:

- 📉 92% reduction in respiratory incidents

- 📆 11-month ROI through productivity gains

Your Next Breath Shouldn't Be a Risk

Book a free air quality audit and get 15% off installation. Limited to first 20 responders this month.

Claim Your Clean Air Advantage →Voted 1 Industrial Air Solution 2023 by IAQA

(welding fume extractor filter)

FAQS on welding fume extractor filter

Q: How often should I replace the welding fume extractor filter?

A: Replace the filter every 6-12 months, depending on usage intensity. Monitor airflow reduction or visible damage as signs for replacement. Always follow manufacturer guidelines for optimal performance.

Q: What types of contaminants do welding fume filter systems remove?

A: They capture hazardous particles like metal oxides, ozone, and fumes from welding/soldering. Advanced systems also filter toxic gases and ultrafine particulates. HEPA filters are ideal for sub-micron particles.

Q: Can a solder fume extractor filter handle high-temperature welding fumes?

A: No—solder fume extractors are designed for lower-temperature soldering. For welding, use a heavy-duty welding fume extractor with heat-resistant filters to withstand intense heat and sparks.

Q: How do I choose between a portable and fixed welding fume filter system?

A: Portable units suit mobile or small-scale operations, while fixed systems are ideal for large workshops. Consider workspace size, frequency of use, and filtration capacity when deciding.

Q: Are welding fume extractor filters reusable or disposable?

A: Some filters (e.g., electrostatic ones) are reusable after cleaning, while others (e.g., pleated or HEPA) are disposable. Check the product specifications to confirm maintenance requirements.

Q: Why is a multi-stage welding fume filter system more effective?

A: Multi-stage systems combine pre-filters, HEPA, and activated carbon layers to capture particles, gases, and odors. This layered approach ensures comprehensive filtration and extends filter lifespan.

Q: Where should I position a welding fume extractor for maximum efficiency?

A: Place it as close as possible to the fume source (e.g., welding arc). Ensure proper airflow direction and avoid obstructions. Adjustable arms or hoods enhance targeted extraction.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025