- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 13, 2025 10:21

Back To List

welding air filtration systems

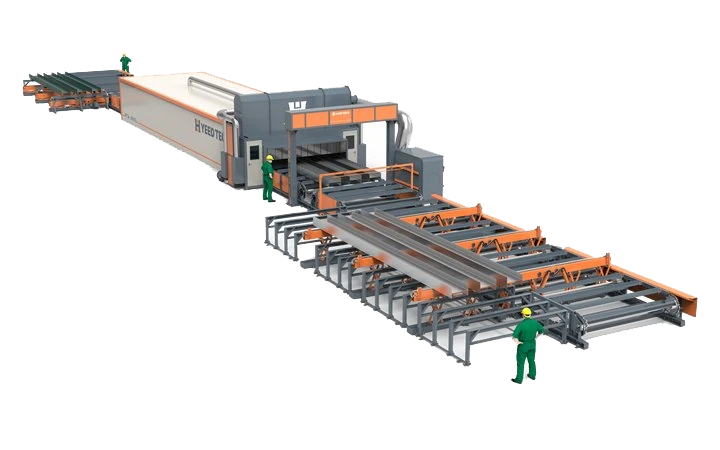

Designing and implementing an automatic spray painting machine project involves a combination of engineering expertise, innovative design, and practical experience. This sophisticated piece of technology aims to redefine efficiency and precision in the painting industry. By minimizing manual labor and human error, it enhances productivity significantly.

Expertise in automation and programming plays a pivotal role in this project. The machine's brain lies in its software, which requires thorough coding and testing to synchronize hardware movements with paint requirements. The program is designed to be user-friendly, allowing operators to program specific tasks with ease. It includes a database of pre-set programs for standard operations, while also offering customization for unique projects. To establish authoritative standing in the industry, collaboration with painting professionals and industrial designers during the development phase is paramount. These partnerships bring insights into industry standards, safety regulations, and user expectations. Continuous feedback from field trials further refines the machine, ensuring it meets the highest standards of performance and safety. Trustworthiness is ensured by adhering to rigorous testing protocols before market release. Each machine undergoes extensive quality assurance processes, including stress testing, precision measurement, and long-term performance assessments. Certification from reputable industry bodies adds an additional layer of credibility, assuring users of the machine's reliability and safety in various environments. The automatic spray painting machine not only promises a revolution in how surfaces are painted but also offers insights into the future of automated industrial processes. Organizations investing in such technology can anticipate improved efficiency, enhanced quality control, and significant cost reductions in their painting operations. This project stands as a testament to the possibilities inherent in combining cutting-edge technology with practical design, embodying a new era of innovation and industrial advancement.

Expertise in automation and programming plays a pivotal role in this project. The machine's brain lies in its software, which requires thorough coding and testing to synchronize hardware movements with paint requirements. The program is designed to be user-friendly, allowing operators to program specific tasks with ease. It includes a database of pre-set programs for standard operations, while also offering customization for unique projects. To establish authoritative standing in the industry, collaboration with painting professionals and industrial designers during the development phase is paramount. These partnerships bring insights into industry standards, safety regulations, and user expectations. Continuous feedback from field trials further refines the machine, ensuring it meets the highest standards of performance and safety. Trustworthiness is ensured by adhering to rigorous testing protocols before market release. Each machine undergoes extensive quality assurance processes, including stress testing, precision measurement, and long-term performance assessments. Certification from reputable industry bodies adds an additional layer of credibility, assuring users of the machine's reliability and safety in various environments. The automatic spray painting machine not only promises a revolution in how surfaces are painted but also offers insights into the future of automated industrial processes. Organizations investing in such technology can anticipate improved efficiency, enhanced quality control, and significant cost reductions in their painting operations. This project stands as a testament to the possibilities inherent in combining cutting-edge technology with practical design, embodying a new era of innovation and industrial advancement.

Prev:

Next:

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025