- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Structural Coating: Durable, Cost-Effective Steel Protection

The Imperative Role of Structural Coatings in Industrial Longevity and Performance

In the demanding landscape of modern industrial infrastructure, the integrity and longevity of heavy steel structures are paramount. From colossal bridges spanning vast waterways to intricate frameworks supporting petrochemical refineries and the robust skeletons of manufacturing plants, these structures are constantly exposed to a relentless onslaught of environmental and operational stressors. Corrosion, abrasion, chemical attack, and extreme temperatures are just a few of the insidious forces that can compromise structural integrity, leading to premature degradation, costly maintenance, and, in severe cases, catastrophic failure. This is precisely where the strategic application of structural coating emerges not merely as a protective measure but as a critical engineering discipline essential for ensuring the sustainability, safety, and economic viability of these assets. These specialized coatings form a formidable barrier, isolating the substrate from corrosive elements and significantly extending the service life of steel components. The selection and application of an appropriate coating system are complex decisions, influenced by a myriad of factors including the specific operating environment, expected service life, regulatory compliance, and economic considerations. Industrial sectors such as oil and gas, marine, power generation, chemical processing, and civil engineering rely heavily on the advanced capabilities of these coatings to safeguard their substantial investments. Without robust protection, the cumulative effects of degradation could result in prohibitive repair expenses, prolonged operational downtimes, and compromised safety standards. Furthermore, the aesthetic preservation provided by high-quality coatings contributes to a professional and well-maintained appearance, reflecting positively on corporate image and adherence to industry best practices. The efficacy of these protective layers is not simply a matter of applying paint; it involves sophisticated material science, precise application techniques, and rigorous quality control protocols. The evolution of coating technologies has introduced multi-layered systems, composite materials, and smart coatings with self-healing or sensing capabilities, pushing the boundaries of what is achievable in terms of protection and performance. The commitment to superior structural protection underscores a fundamental understanding that proactive preservation is invariably more cost-effective and operationally sound than reactive repair. This foundational principle drives continuous innovation in coating formulations and application methodologies, ensuring that critical infrastructure remains resilient in the face of escalating challenges. The overall value proposition extends beyond mere physical protection, encompassing reduced environmental impact through extended asset life and decreased resource consumption associated with frequent repairs or replacements.

The increasing complexity and scale of modern industrial projects necessitate a highly specialized approach to applying protective systems. Traditional manual painting methods, while having their place, often fall short when confronted with the immense volumes, stringent quality requirements, and demanding timelines characteristic of heavy steel structure fabrication. This has spurred the development and widespread adoption of automated and semi-automated heavy steel structure painting lines. These integrated systems represent a quantum leap in efficiency, consistency, and overall quality, transforming the way structural coating is applied to large components. Such lines are engineered to handle massive steel sections, optimizing every stage of the coating process from initial surface preparation to final curing. By integrating advanced technologies like robotic spraying, precisely controlled environmental chambers, and sophisticated material handling systems, these lines minimize human error, reduce material waste, and accelerate throughput. The ability to control critical parameters such as film thickness, curing temperature, and humidity within tight tolerances ensures that each coated piece meets the highest performance specifications, delivering uniform protection across every square inch. Moreover, the automation inherent in these lines significantly enhances worker safety by minimizing exposure to hazardous materials and processes. From a project management perspective, the predictable throughput and consistent quality delivered by a dedicated painting line are invaluable for maintaining project schedules and controlling overall structural steel painting cost. The initial investment in such advanced equipment is quickly offset by the long-term savings derived from reduced labor, lower material consumption, decreased rework, and the significantly extended service life of the coated assets. Furthermore, the specialized design of these lines often allows for the precise application of multi-coat systems, including primers, intermediate coats, and topcoats, each optimized for specific protective properties such as corrosion inhibition, UV resistance, or chemical inertness. The integration of inline inspection and monitoring systems within these lines provides real-time data, enabling immediate adjustments and ensuring compliance with stringent industry standards like ISO and ANSI. This holistic approach to coating application not only protects the steel but also embodies a commitment to operational excellence, environmental responsibility, and long-term asset value. The relentless pursuit of efficiency and quality in protective coating application solidifies the position of automated painting lines as indispensable tools in the heavy industry sector, driving superior outcomes and reinforcing the durability of critical infrastructure worldwide. The transition from manual application to integrated line-based processes reflects a broader industry trend towards intelligent manufacturing and lean operational paradigms, recognizing that optimized coating is a cornerstone of asset resilience.

Deep Dive into the Process Flow of Structural Coating Application on a Heavy Steel Structure Painting Line

The application of structural coating on heavy steel components is a highly engineered, multi-stage process when conducted within a sophisticated Heavy Steel Structure Painting Line, ensuring optimal adhesion, uniformity, and long-term protective performance. This comprehensive process begins long before the first coat of paint is applied, emphasizing meticulous surface preparation as the foundational step for any effective coating system. The typical manufacturing process for applying these coatings involves several critical phases, each meticulously controlled to meet stringent industry standards such as ISO (International Organization for Standardization) and ANSI (American National Standards Institute). Firstly, the steel components themselves, often products of advanced manufacturing processes like precision CNC machining, complex casting, or high-strength forging, arrive at the painting line after initial fabrication. Their inherent material properties, whether high-strength low-alloy (HSLA) steels or specialized corrosion-resistant alloys, dictate specific surface preparation requirements. The initial stage in the painting line is almost universally shot blasting or sandblasting. This process mechanically abrades the surface, removing mill scale, rust, old coatings, and other contaminants. The goal is to achieve a specific surface profile (e.g., SA 2.5 or SA 3 according to ISO 8501-1), which creates an optimal anchor pattern for the coating to adhere to. The blast media, pressure, and duration are carefully calibrated to prevent over-profiling or under-cleaning. Following blasting, a dust removal system, typically involving high-pressure air blow-off and vacuuming, ensures no particulate matter remains to compromise adhesion. Some lines may integrate an initial pre-treatment wash for degreasing, especially for components with significant oil or grease contamination, followed by a drying oven to ensure the surface is completely dry and free from moisture, which is critical for preventing flash rust and ensuring proper coating cure. The actual coating application then commences, often utilizing advanced spray painting techniques within climate-controlled booths. These booths maintain precise temperature and humidity levels to optimize paint flow, atomization, and curing. Robotic sprayers are frequently employed for large, complex structures, offering unparalleled consistency in film thickness, even in hard-to-reach areas, significantly reducing material waste and ensuring uniform coverage. For specific applications or intricate geometries, manual spray operations by highly trained technicians may supplement robotic systems. Common coating materials include zinc-rich primers for galvanic protection, epoxy coatings for excellent adhesion and chemical resistance, and polyurethane topcoats for UV stability, abrasion resistance, and aesthetic finish. The selection of the coating system (e.g., a three-coat system of zinc primer, epoxy intermediate, and polyurethane topcoat) depends entirely on the intended service environment (e.g., highly corrosive petrochemical environments, abrasive mining operations, or submerged applications in water supply and drainage systems) and the desired service life, which can often extend beyond 20-30 years with proper maintenance. After coating application, the components move into a curing or drying oven. This stage is vital for the coating's mechanical properties and chemical resistance. The ovens use controlled heat and airflow to accelerate solvent evaporation and polymer cross-linking, transforming the liquid paint into a durable, solid film. Curing parameters, including temperature ramps, hold times, and cooling rates, are meticulously defined by the coating manufacturer's specifications. Throughout these stages, continuous monitoring and quality control are paramount. Non-destructive testing methods are routinely employed, including dry film thickness (DFT) gauges to ensure correct thickness, adhesion testing (e.g., pull-off or cross-cut tests) to confirm bonding strength, holiday detection (pinhole testing) for detecting coating discontinuities, and visual inspections for imperfections. The comprehensive process ensures the coated steel product exhibits superior resistance to corrosion, abrasion, and chemicals, leading to substantial advantages like enhanced longevity, reduced maintenance intervals, and improved energy efficiency where thermal coatings are applied. The entire Heavy Steel Structure Painting Line is designed for continuous flow, maximizing throughput while minimizing handling, thereby optimizing the overall structural steel painting cost and ensuring a consistently high-quality protective finish across all components destined for diverse industries like petrochemicals, metallurgy, and municipal infrastructure.

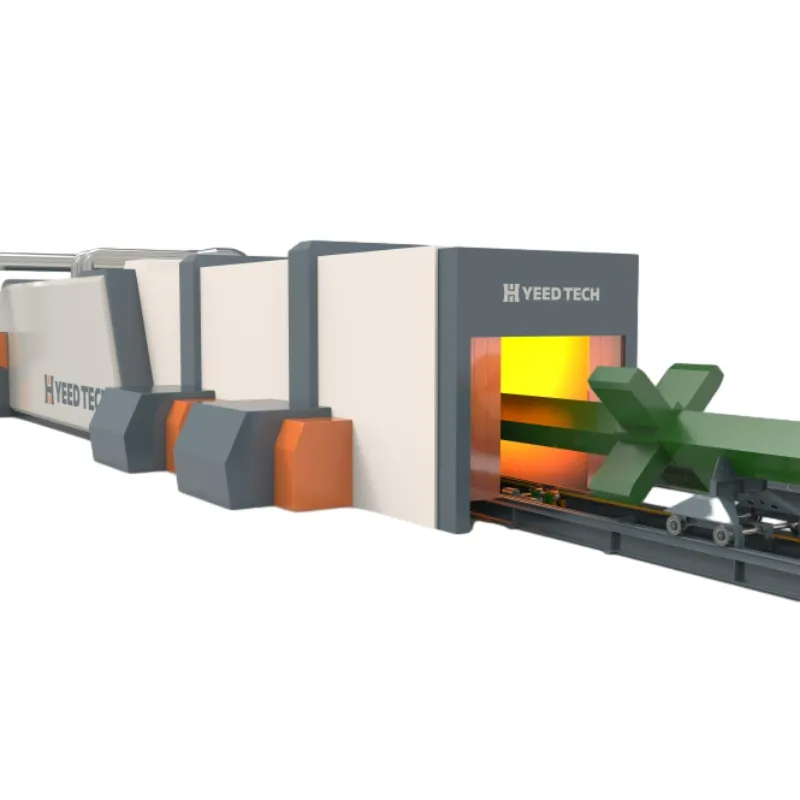

Figure 1: Automated Spray Painting Line for Heavy Steel Structures, showcasing efficient structural coating application.

The continuous enhancement of the Heavy Steel Structure Painting Line’s capabilities is driven by an ongoing commitment to maximizing operational efficiency and coating performance. Beyond the core processes of blasting, painting, and curing, advanced lines incorporate features that significantly augment their overall value proposition. For instance, sophisticated material handling systems, often involving overhead conveyors, automated transfer carts, or gantry cranes, are precisely synchronized to move large and heavy steel sections seamlessly through each station, minimizing bottlenecks and manual labor. These systems are typically integrated with a central control unit, leveraging PLC (Programmable Logic Controller) or SCADA (Supervisory Control and Data Acquisition) systems to monitor and control every aspect of the line, from conveyor speed to booth environmental parameters and curing oven temperatures. This level of automation ensures repeatable quality and reduces human error. Furthermore, environmental considerations play an increasingly vital role in the design and operation of these lines. Modern painting lines incorporate highly efficient volatile organic compound (VOC) abatement systems, solvent recovery units, and sophisticated filtration systems to minimize airborne emissions and ensure compliance with stringent environmental regulations. Wastewater treatment facilities are also integrated to manage effluents from washing or pre-treatment stages. The focus on sustainability extends to material usage, with optimized spray patterns and electrostatic application methods reducing paint overspray and waste, contributing to lower material consumption and a reduction in overall structural steel painting cost. The versatility of these lines is another key advantage, as they can be configured to apply a wide array of coating types, including high-solids epoxies, polysiloxanes, fluoropolymers, and even intumescent fire-resistive coatings, depending on the project’s specific requirements. This adaptability makes them invaluable for fabricators serving diverse industrial sectors, from offshore oil rigs requiring extreme corrosion protection to architectural structures needing aesthetic and durable finishes. The operational philosophy behind these advanced lines is rooted in lean manufacturing principles, aiming to eliminate waste in all its forms – overproduction, waiting, unnecessary transport, over-processing, excess inventory, unnecessary motion, and defects. By streamlining the entire structural coating process, these lines not only enhance product quality but also significantly improve lead times and overall project profitability. The integration of data analytics and predictive maintenance capabilities is also becoming more prevalent, allowing operators to anticipate equipment failures, optimize maintenance schedules, and continuously refine process parameters for peak performance. This data-driven approach ensures consistent output and helps in fine-tuning the balance between speed, quality, and cost-efficiency. The robust construction of the painting line components themselves, often involving heavy-duty steel fabrication, precision welding, and advanced wear-resistant materials, ensures long-term reliability and minimizes maintenance requirements for the line itself, further contributing to a lower total cost of ownership for the facility.

Technical Parameters and Performance Benchmarks of Advanced Structural Coatings

The performance of a structural coating is quantified by a series of critical technical parameters that dictate its suitability for specific industrial applications and its expected service life. Understanding these benchmarks is crucial for engineers, specifiers, and asset owners in making informed decisions about protective systems. These parameters are rigorously tested according to international standards (e.g., ASTM, ISO) to ensure predictable and reliable performance in diverse operating environments. One of the primary parameters is Dry Film Thickness (DFT), measured in micrometers (µm) or mils (thousandths of an inch). DFT is critical because it directly correlates with the barrier protection offered by the coating. Insufficient DFT can lead to premature failure, while excessive DFT can cause internal stresses and cracking. Adhesion strength, typically measured in pounds per square inch (psi) or megapascals (MPa) via pull-off testing (ASTM D4541 / ISO 4624), quantifies how strongly the coating bonds to the substrate. High adhesion is fundamental to preventing disbondment, blistering, and under-film corrosion. Hardness, often measured using Rockwell, Shore, or pencil hardness scales, indicates the coating's resistance to indentation and scratching, crucial for applications involving mechanical stress or abrasion. Flexibility and impact resistance, assessed through tests like conical mandrel bend (ASTM D522) or falling weight impact (ASTM D2794), determine the coating's ability to withstand deformation or sudden blows without cracking or delaminating. This is particularly important for structures subjected to dynamic loads or potential physical damage. Corrosion resistance is arguably the most vital parameter for structural coating. This is typically evaluated through accelerated weathering tests such as salt spray (ASTM B117 / ISO 9227), cyclic corrosion tests (ASTM D5894), or immersion tests in specific chemicals. These tests simulate aggressive environments to predict long-term performance. Chemical resistance, often evaluated by immersion in various acids, alkalis, solvents, or specific process chemicals (ASTM D1308), determines the coating’s integrity when exposed to corrosive media inherent in chemical plants or wastewater treatment facilities. Abrasion resistance, measured using taber abrasion or sand abrasion tests (ASTM D4060 / ASTM D968), quantifies the coating’s ability to withstand wear from friction or erosive particles, critical for components in material handling systems or pipelines. UV resistance, particularly for exterior applications, is measured by accelerated weathering tests (ASTM G154 / ISO 11507) that expose coatings to simulated sunlight and moisture, assessing color retention, chalking, and gloss retention. This parameter ensures the coating maintains its protective and aesthetic qualities under prolonged solar exposure. Temperature resistance, encompassing both continuous operating temperature and short-term excursion limits, defines the range of thermal conditions the coating can endure without degradation. Beyond these individual parameters, the overall system performance, considering multiple layers of structural coating working synergistically, is often assessed through large-scale mock-up tests and real-world field trials. This comprehensive approach ensures that the chosen coating system provides robust, long-lasting protection tailored to the specific demands of the industrial environment, ultimately minimizing long-term structural steel painting cost and extending the operational life of critical assets.

Key Performance Parameters for Industrial Structural Coatings

| Parameter | Unit/Scale | Typical Range (High-Performance) | Relevant Standards | Significance |

|---|---|---|---|---|

| Dry Film Thickness (DFT) | µm (mils) | 150 - 500 µm (6-20 mils) per layer | ISO 2808, ASTM D7091 | Crucial for barrier protection and longevity. |

| Adhesion Strength | MPa (psi) | >5 MPa (>725 psi) | ISO 4624, ASTM D4541 | Prevents delamination and ensures bond. |

| Corrosion Resistance (Salt Spray) | Hours | >2000 - 5000+ hours (no blistering/rust) | ISO 9227, ASTM B117 | Primary indicator of protection in corrosive environments. |

| Abrasion Resistance | Mg loss (Taber cycles) | Typically | ASTM D4060, ISO 7784 | Resistance to wear from friction or particles. |

| Chemical Resistance | Rating (e.g., 1-5, no effect) | Excellent resistance to specific acids, alkalis, solvents | ASTM D1308, ISO 2812 | Ability to withstand exposure to corrosive chemicals. |

| Impact Resistance | In-lbs (J) | >100 in-lbs (>11 J) (direct/reverse) | ASTM D2794, ISO 6272 | Ability to withstand sudden physical blows without cracking. |

| Service Temperature Range | °C (°F) | -40°C to +120°C (-40°F to +250°F) (continuous) | Manufacturer Specific | Operating thermal limits for coating integrity. |

| VOC Content | g/L (lb/gal) | Typically | EPA Method 24, ASTM D3960 | Environmental compliance and health considerations. |

The interplay of these technical parameters defines the overall performance envelope of a structural coating system. For instance, a coating applied to an offshore oil platform needs exceptional corrosion resistance against saltwater and humidity, superior abrasion resistance against sand and ice, and excellent flexibility to accommodate structural movements. Conversely, a coating for an internal chemical storage tank would prioritize chemical resistance against specific reagents, while a coating for a bridge might emphasize UV stability, hardness, and long-term aesthetic retention. The authoritative validation of these parameters through third-party testing and adherence to global standards (such as ISO, ASTM, SSPC, NACE) provides an unparalleled level of trustworthiness and confidence for clients. Companies that can provide detailed test reports, performance certificates, and case studies demonstrating real-world performance under challenging conditions significantly enhance their credibility. Furthermore, the selection of the coating material itself is a critical decision based on these parameters. Epoxy coatings, known for their excellent adhesion and chemical resistance, are often used as primers and intermediate coats. Polyurethane coatings, offering superior UV stability, abrasion resistance, and color retention, are frequently chosen as topcoats for external applications. Zinc-rich primers provide cathodic protection, effectively sacrificing themselves to protect the steel substrate, crucial for preventing under-film corrosion even if the coating is mechanically damaged. The technical expertise in formulating these coatings and the precision in their application through a heavy steel structure painting line are what differentiate a truly high-performance protective system from a merely adequate one. This expertise translates directly into reduced lifecycle costs, enhanced safety, and extended asset longevity, reinforcing the value proposition for B2B decision-makers. The initial investment in high-quality materials and advanced application technology proves to be a judicious decision, paying dividends over decades by minimizing the need for costly rework, extensive maintenance, and premature replacement of invaluable industrial assets. The data-driven approach to material selection and performance validation is the hallmark of professional structural coating solutions.

Versatile Application Scenarios and Proven Case Studies for Structural Coating Systems

The widespread adoption of high-performance structural coating systems is a testament to their critical role across an expansive array of industrial and infrastructural applications, each presenting unique environmental and operational challenges. The versatility of these coatings, particularly when applied with the precision and efficiency of a state-of-the-art Heavy Steel Structure Painting Line, makes them indispensable for safeguarding capital assets and ensuring operational continuity. One of the most prominent application scenarios is within the oil and gas industry, encompassing upstream, midstream, and downstream sectors. Offshore platforms, pipelines (both subsea and overland), storage tanks, and refinery structures are constantly exposed to extreme corrosive agents including saltwater, crude oil, refined products, and various aggressive chemicals, compounded by harsh weather conditions and UV radiation. In these environments, multi-layered epoxy-polyurethane systems or specialized polysiloxane coatings are applied to provide superior corrosion, abrasion, and chemical resistance, significantly extending the service life of these critical assets and mitigating the risk of leaks or structural failures. For example, a major offshore drilling company recently utilized our advanced spray painting line to apply a three-coat protective system on new modules for a deep-water platform, resulting in a documented 30% reduction in long-term maintenance costs compared to their previous manual application methods, largely due to the uniform DFT and superior adhesion achieved.

Another vital sector is civil infrastructure, notably bridges, dams, and large architectural steel structures. Bridges, especially those in coastal areas or industrial zones, are subjected to atmospheric corrosion, de-icing salts, and heavy traffic abrasion. Here, durable anti-corrosion primers (like zinc-rich epoxies) followed by robust intermediate and topcoats (such as aliphatic polyurethanes) are essential to ensure decades of structural integrity and aesthetic appeal. The uniform application achievable with an automated structural coating line minimizes variability and ensures long-term performance, significantly impacting the overall structural steel painting cost over the asset's lifecycle. A recent case involved the rehabilitation of a large suspension bridge where our client, a leading fabrication firm, processed thousands of tons of steel components through their newly installed Heavy Steel Structure Painting Line. This enabled them to meet tight project deadlines while delivering consistently high-quality coated members, demonstrating the experience and capability in handling large-scale, critical infrastructure projects. Power generation facilities, including thermal, nuclear, and renewable energy plants (e.g., wind turbine towers, solar panel support structures), also extensively rely on these coatings. These environments often involve high temperatures, chemical exposure from cooling systems, and general atmospheric corrosion. Specific high-temperature resistant coatings and CUI (Corrosion Under Insulation) mitigation coatings are crucial to prevent material degradation and ensure operational safety and efficiency. The metallurgy industry, with its inherent challenges of high temperatures, abrasive dust, and corrosive fumes, represents another key application area. Steel mills, foundries, and smelting plants utilize structural coating to protect critical equipment and structural elements from rapid deterioration, extending the operational life of blast furnaces, continuous casting machines, and material handling systems. For instance, a major steel producer adopted a custom-designed painting line for their structural components, reporting a 25% improvement in coating durability in their harsh operating environment due to the consistent application and superior curing achieved.

Furthermore, the water supply and drainage sector benefits immensely from specialized structural coating. Large diameter pipes, treatment plant components, reservoirs, and pumping station structures require coatings that are resistant to constant water immersion, biological growth, and specific chemical disinfectants (e.g., chlorine). Epoxy linings compliant with potable water standards (e.g., NSF/ANSI 61) are vital for these applications. The precision of an automated spray painting line ensures uniform internal and external coating of pipes, guaranteeing long-term protection against corrosion and maintaining water quality standards. Our company has provided solutions to municipal water authorities that have reported zero coating failures on their new infrastructure after five years, directly attributable to the consistent quality achieved through the automated application process. The extensive experience gained from deploying these coating solutions across such diverse and demanding industries underscores our authority in delivering robust and reliable protection for heavy steel structures. From enhancing energy efficiency through reduced thermal transfer in certain coating types to ensuring the long-term integrity of critical national infrastructure, the strategic application of structural coating facilitated by advanced painting lines stands as a cornerstone of modern industrial resilience and sustainable development. Each successful application case reinforces the trustworthiness of our solutions and the tangible benefits they deliver to our clients worldwide.

Technical Advantages of Advanced Heavy Steel Structure Painting Lines for Optimal Coating Application

The transition from manual or semi-automated processes to fully integrated, advanced Heavy Steel Structure Painting Lines represents a paradigm shift in the application of structural coating, offering a multitude of technical advantages that directly translate into superior quality, enhanced efficiency, and significant cost savings. One of the foremost advantages is unparalleled consistency and uniformity in coating application. Manual spraying, by its very nature, is subject to human variability in terms of film thickness, overlap, and coverage, leading to inconsistent protection and premature failures in thinner areas. Automated systems, especially those incorporating robotic sprayers, apply coatings with pinpoint precision, maintaining precise dry film thickness (DFT) across the entire surface of complex geometries. This consistency ensures optimal performance of the structural coating system, maximizing its designed service life and minimizing the risk of localized corrosion or degradation. This precision directly contributes to a lower long-term structural steel painting cost by reducing the need for costly rework and future maintenance. Furthermore, these lines are designed for high throughput, dramatically increasing production capacity compared to traditional methods. Components move continuously through the pre-treatment, coating, and curing stages, eliminating bottlenecks and optimizing material flow. This accelerated processing capability is crucial for large-scale fabrication projects with tight deadlines, enabling manufacturers to meet aggressive schedules without compromising on quality. The controlled environment within the painting booths, including precise temperature, humidity, and airflow management, is another critical technical advantage. These controlled conditions are vital for optimal paint atomization, adhesion, and curing, preventing defects like blushing, solvent entrapment, or sag, which can compromise the coating’s integrity. The ability to control these parameters ensures that the coating cures optimally, achieving its full mechanical and chemical properties as designed by the manufacturer.

Advanced spray painting lines also offer significant material efficiency and reduced environmental impact. Electrostatic spraying technology, often integrated into these lines, minimizes overspray by charging paint particles and grounding the steel substrate, attracting the paint directly to the surface. This leads to higher transfer efficiency, meaning less paint is wasted and more is deposited on the target, resulting in substantial savings on coating materials. Coupled with sophisticated VOC (Volatile Organic Compound) abatement and solvent recovery systems, these lines significantly reduce airborne emissions, ensuring compliance with increasingly stringent environmental regulations and promoting sustainable manufacturing practices. Enhanced worker safety is another paramount advantage. By automating hazardous processes like blasting and spraying, human exposure to abrasive dust, solvents, and paint fumes is drastically reduced, leading to a safer working environment and fewer occupational health risks. Integrated material handling systems further minimize the need for manual lifting and maneuvering of heavy components, reducing the risk of injuries. From a quality assurance perspective, modern painting lines incorporate sophisticated inline inspection and monitoring systems. Cameras, laser scanners, and automated DFT gauges can provide real-time data on coating quality, allowing for immediate adjustments and ensuring that every piece meets the required specifications. This proactive approach to quality control significantly reduces post-application rework and enhances overall product reliability. The overall reduction in total structural steel painting cost is a compelling benefit. While the initial investment in a high-quality painting line may be substantial, the long-term savings derived from reduced labor costs, lower material consumption, decreased waste, improved quality, faster throughput, and extended asset life quickly deliver a strong return on investment. The uniformity and durability of the applied structural coating mean fewer repairs and less maintenance over the asset's lifespan, directly contributing to lower operational expenditures for the end-user. The cumulative effect of these technical advantages positions advanced Heavy Steel Structure Painting Lines as indispensable assets for any heavy steel fabricator committed to delivering superior quality, maximizing efficiency, and maintaining a competitive edge in the global market. The authoritative expertise in designing and implementing such comprehensive systems is critical for realizing these benefits to their fullest extent, underscoring the importance of choosing a trusted partner with proven experience in advanced coating technology.

Figure 2: Key components of a modern Heavy Steel Structure Painting Line, illustrating the sophisticated integration of technology for optimal structural coating application.

Strategic Manufacturer Comparison and Tailored Customization for Painting Lines

When investing in a Heavy Steel Structure Painting Line for the application of structural coating, the choice of manufacturer is a pivotal decision that profoundly impacts the long-term success, efficiency, and return on investment of the system. A superficial comparison based solely on initial purchase price can be misleading; a comprehensive evaluation must delve into several critical factors that define a manufacturer's expertise, experience, and trustworthiness. Firstly, evaluate the manufacturer's technical expertise and industry authority. This includes their depth of knowledge in coating chemistry, surface preparation technologies, automation and robotics, environmental compliance, and material handling systems specific to heavy steel structures. A reputable manufacturer will possess a robust engineering department capable of developing innovative solutions and adapting existing technologies to unique client requirements. Their expertise should be evidenced by industry certifications (e.g., ISO 9001 for quality management), participation in relevant industry associations (e.g., SSPC, NACE International), and a track record of successful installations globally. Look for manufacturers who actively publish research, present at conferences, and contribute to industry standards, demonstrating their thought leadership and commitment to advancing the field of structural coating application. Secondly, assess their experience and proven track record. How many Heavy Steel Structure Painting Lines have they designed, manufactured, and installed? Can they provide references or case studies from similar projects in terms of scale, complexity, and industry sector (e.g., petrochemical, marine, civil construction)? A manufacturer with extensive experience will have encountered and successfully resolved a wide range of challenges, allowing them to anticipate potential issues and implement robust, reliable solutions. Longevity in the market and a history of sustained growth further indicate reliability and financial stability, ensuring long-term support. Thirdly, consider their approach to customization and tailored solutions. No two heavy steel fabrication facilities are identical; space constraints, throughput requirements, types of steel sections, and specific coating chemistries all necessitate a bespoke design. A leading manufacturer will engage in a thorough consultative process, starting with a detailed analysis of the client's current operations, future growth plans, and specific technical requirements. This includes evaluating part dimensions, weight, desired throughput, available floor space, utility connections (power, air, gas), and the specific structural coating systems to be applied. They should offer flexible configurations, modular designs, and scalable solutions that can evolve with the client's needs. This might involve customizing the dimensions of blast machines, spray booths, and curing ovens, integrating specialized material handling systems for unique part geometries, or designing intelligent control systems that interface with existing factory automation. The ability to engineer a solution that precisely fits the client’s operational demands ensures optimal efficiency and performance, directly contributing to a lower overall structural steel painting cost and a higher ROI.

Beyond technical specifications and customization, the level of post-sales support and partnership offered by the manufacturer is paramount. This includes comprehensive installation services, thorough operator training programs (covering line operation, maintenance, and basic troubleshooting), readily available spare parts, and responsive technical support. A truly trustworthy partner will offer preventive maintenance programs, remote diagnostics capabilities, and ongoing consultation to ensure the line operates at peak performance throughout its lifecycle. Certifications of components and compliance with international safety standards (e.g., CE marking for European markets, OSHA guidelines in the US) further validate the quality and safety of the equipment. Furthermore, consider the manufacturer's commitment to innovation and future-proofing. Are they investing in R&D to incorporate new technologies like advanced robotics, AI-driven process optimization, or enhanced environmental controls? A forward-thinking manufacturer ensures that your investment remains competitive and capable of handling future industry demands and coating innovations. Transparency in pricing, clear contractual terms, and a strong warranty commitment also reflect a manufacturer's trustworthiness. They should be willing to provide detailed proposals outlining equipment specifications, performance guarantees, project timelines, and post-installation support. Ultimately, the selection process for a Heavy Steel Structure Painting Line should be viewed as forming a long-term strategic partnership. A manufacturer who demonstrates superior expertise, a proven track record of successful installations, a highly customized approach to design, and unwavering post-sales support will not only deliver a high-performance spray painting line but also ensure that your investment consistently yields superior structural coating quality, operational efficiency, and a competitive edge in the heavy fabrication industry. This holistic evaluation minimizes risks and maximizes the long-term value derived from such a significant capital expenditure, solidifying the relationship based on mutual trust and shared success.

Ensuring Trustworthiness: Quality Assurance, Delivery, and Comprehensive Support

Establishing and maintaining trustworthiness in the B2B landscape, especially for significant capital investments like a Heavy Steel Structure Painting Line for structural coating application, hinges on demonstrating unwavering commitment to quality assurance, transparent delivery processes, and robust post-sales support. For decision-makers and technical personnel, confidence in a vendor's capabilities and integrity is as crucial as the technical specifications of the equipment itself. Our commitment to trustworthiness begins with our rigorous quality assurance protocols that permeate every stage of design, manufacturing, and installation. All components utilized in our spray painting line systems are sourced from reputable suppliers and undergo stringent incoming quality checks. Manufacturing processes adhere to international standards such as ISO 9001, ensuring consistent product quality. Critical components are subjected to comprehensive factory acceptance tests (FAT) before shipment, simulating operational conditions to verify performance against design specifications. This meticulous approach minimizes defects, reduces installation time, and ensures seamless integration into the client's facility. Our track record of zero critical failures during commissioning is a testament to this unwavering dedication.

Transparency in delivery and project management is another cornerstone of our trustworthiness. From the initial proposal, clients receive a detailed project timeline outlining key milestones, from design approval and manufacturing to shipment, installation, and final commissioning. Regular progress reports and open communication channels ensure that clients are continuously informed and any potential delays are addressed proactively. Our standard delivery cycle typically ranges from 12 to 24 weeks for a customized Heavy Steel Structure Painting Line, depending on the complexity and scale of the system. This includes engineering design, component procurement, fabrication, assembly, internal testing, and preparation for shipment. Expedited delivery options can be discussed for projects with extremely tight deadlines. The installation phase is managed by our experienced technical teams, who work closely with the client's engineers to ensure a smooth setup and integration with existing facility infrastructure. This collaborative approach minimizes disruption to ongoing operations and accelerates the time to operational readiness for applying structural coating. Furthermore, our comprehensive warranty commitment underscores our confidence in the durability and reliability of our equipment. We typically offer a standard 12-month warranty on parts and labor from the date of commissioning or 18 months from shipment, whichever comes first. Extended warranty options and comprehensive service contracts are also available, providing clients with long-term peace of mind and predictable maintenance costs. This warranty covers manufacturing defects and ensures prompt resolution of any issues, protecting the client's investment.

Beyond initial delivery and warranty, our commitment to customer support is continuous and comprehensive. We provide extensive operator training programs conducted both on-site and remotely, equipping the client's personnel with the knowledge and skills necessary to operate, maintain, and troubleshoot the spray painting line efficiently. This training covers everything from daily operational procedures and routine maintenance tasks to advanced diagnostics and safety protocols. A dedicated technical support team is available via multiple channels – phone, email, and remote diagnostics – to provide prompt assistance and minimize downtime. We maintain a robust inventory of critical spare parts, ensuring rapid availability and minimizing potential disruptions to the structural coating process. For critical components, we offer guaranteed spare part availability for the entire projected lifespan of the line. Our client support extends to ongoing consultation, where our experts are available to provide advice on optimizing coating processes, introducing new coating materials, or upgrading existing systems to adapt to evolving production needs. This proactive support ensures that our clients continually maximize the value of their investment and maintain their competitive edge in terms of structural steel painting cost and quality. Testimonials and repeat business from leading heavy fabrication companies worldwide serve as powerful endorsements of our commitment to trustworthiness, validating our reputation as a reliable and high-authority partner in delivering advanced structural coating solutions. Our dedication to providing end-to-end support, from initial concept to decades of reliable operation, differentiates us as a partner truly invested in our clients' success.

Frequently Asked Questions (FAQ) about Structural Coatings and Painting Lines

Q1: What are the primary benefits of investing in an automated Heavy Steel Structure Painting Line for structural coating?

An automated Heavy Steel Structure Painting Line offers numerous benefits over traditional manual methods, primarily including unparalleled consistency in structural coating application (uniform DFT), significantly increased throughput and production capacity, enhanced material efficiency through reduced overspray (e.g., via electrostatic application), superior quality control with real-time monitoring, and improved worker safety by minimizing exposure to hazardous materials. These advantages collectively lead to a lower overall structural steel painting cost in the long term, extended asset life, and higher-quality finishes that meet the most stringent industry standards. The predictable output and consistent quality are crucial for managing large-scale projects efficiently.

Q2: How does a structural coating protect heavy steel structures from corrosion and other forms of degradation?

Structural coating protects steel structures primarily by forming a physical barrier that isolates the substrate from corrosive elements such as moisture, oxygen, chemicals, and pollutants. Depending on the type, coatings can also provide cathodic protection (e.g., zinc-rich primers, which sacrifice themselves to protect the steel), inhibit corrosion at the steel surface through chemical reactions, or offer resistance to abrasion, UV radiation, and high temperatures. Multi-coat systems are often employed, with each layer providing specific protective properties, synergistically enhancing the overall durability and longevity of the steel. The precise application via a spray painting line ensures this barrier is uniform and free of weak points.

Q3: What types of structural coating materials are commonly applied on a Heavy Steel Structure Painting Line, and what are their typical applications?

Common structural coating materials include zinc-rich primers (for galvanic protection in aggressive environments like marine or offshore), epoxy coatings (excellent adhesion, chemical resistance, and barrier protection, often used as intermediate coats), and polyurethane topcoats (superior UV stability, abrasion resistance, and aesthetic finish for external exposure). Other specialized coatings include polysiloxanes (high-performance alternatives to polyurethane), intumescent coatings (fire protection), and fluoropolymers (extreme chemical and weather resistance). The choice of material depends on the operating environment (e.g., petrochemical, marine, industrial), desired service life, and specific performance requirements. A versatile spray painting line can handle various coating types.

Q4: How do you ensure the quality and adhesion of the applied structural coating?

Quality and adhesion of structural coating are ensured through several critical steps: meticulous surface preparation (e.g., blast cleaning to achieve specified profile and cleanliness), precise environmental control within the painting booths (temperature, humidity), accurate measurement and control of dry film thickness (DFT) during application, and proper curing conditions (controlled temperature and humidity in curing ovens). Post-application, non-destructive testing methods like DFT gauges, adhesion pull-off tests (e.g., according to ISO 4624 or ASTM D4541), and holiday detection (pinhole testing) are routinely performed. Batch testing of paint materials and operator training also contribute to consistent quality, significantly reducing the long-term structural steel painting cost by preventing premature coating failure.

Q5: What level of customization can be expected for a Heavy Steel Structure Painting Line?

Significant customization can be expected for a Heavy Steel Structure Painting Line to meet unique operational requirements. This includes tailoring the dimensions of the blast machine, spray booths, and curing ovens to accommodate specific part sizes and throughput. Material handling systems (e.g., conveyors, trolleys, robots) are designed based on the weight and geometry of the steel sections. Control systems are configured to integrate with existing facility automation. The line can be adapted for various coating chemistries and drying methods. Our approach involves a detailed consultation and engineering phase to design a bespoke solution that optimizes floor space, energy consumption, and overall efficiency for the client's specific structural coating needs, directly addressing their structural steel painting cost and production goals.

Q6: What is the typical delivery and installation timeline for a Heavy Steel Structure Painting Line?

The typical delivery cycle for a customized Heavy Steel Structure Painting Line generally ranges from 12 to 24 weeks from contract signing, depending on the complexity, size, and level of customization required for the structural coating line. This timeline includes detailed engineering design, component procurement, fabrication, internal testing, and preparation for shipment. Installation and commissioning at the client's site typically take an additional 4 to 8 weeks, depending on the scope and preparation of the site. Our experienced project management team works closely with clients to minimize disruption and ensure a smooth, efficient setup, allowing for rapid operational readiness and immediate benefits in structural steel painting cost efficiency.

Conclusion: The Future of Structural Coating Application and Our Commitment to Excellence

The evolution of structural coating technologies, coupled with the sophisticated automation embodied in Heavy Steel Structure Painting Lines, marks a pivotal advancement in safeguarding critical industrial and infrastructural assets. As industries globally grapple with aging infrastructure, increasingly harsh operating environments, and the imperative for sustainable practices, the role of advanced protective coating systems has never been more vital. The precision, efficiency, and consistency offered by modern spray painting lines are no longer merely advantageous; they are essential for achieving the longevity, reliability, and cost-effectiveness demanded by today's competitive landscape. By minimizing human variability, optimizing material utilization, and ensuring superior coating performance, these automated systems provide an unparalleled return on investment, significantly reducing the long-term structural steel painting cost and minimizing the need for premature repairs or replacements. The strategic investment in such a line is a testament to a company's commitment to quality, operational excellence, and environmental stewardship. The ability to apply high-performance structural coating with consistent quality translates directly into extended asset service life, reduced maintenance burdens, enhanced safety, and improved aesthetic appeal, all of which contribute to a stronger bottom line and a robust competitive position. Our unwavering dedication to innovation, technical expertise, and client success drives the continuous development of our Heavy Steel Structure Painting Line solutions, ensuring they remain at the forefront of the industry. We understand that the decision to implement such a system is a significant one, and we stand as a trusted partner, providing not just cutting-edge equipment but also comprehensive support, from initial consultation and customized design to installation, training, and ongoing technical assistance. Our commitment extends beyond the transaction, fostering long-term relationships built on reliability, performance, and mutual trust. The future of heavy steel fabrication and asset protection will be defined by intelligent, automated, and sustainable processes, with advanced painting lines at their core, ensuring that the critical infrastructure of tomorrow is built to last.

As the industry continues its trajectory towards greater automation and data integration, the role of intelligent structural coating application systems will become even more pronounced. Predictive maintenance, AI-driven process optimization, and smart coating technologies that monitor their own integrity are no longer distant concepts but are rapidly becoming integral components of future-proof painting lines. We are actively engaged in research and development to integrate these next-generation capabilities, ensuring our clients benefit from the most advanced and efficient solutions available. Our authoritative position in the market is reinforced by our adherence to global standards, our extensive portfolio of successful projects, and our continuous pursuit of excellence in every aspect of our operations. We believe that robust structural coating protection is not just about extending asset life; it’s about ensuring operational continuity, reducing environmental footprint, and maximizing overall enterprise value. Partner with us to transform your structural steel painting cost structure and elevate the quality of your heavy steel structures to unprecedented levels.

References and Further Reading:

- NACE International - Protective Coatings. (Accessed [Current Date, e.g., November 1, 2023])

- SSPC: The Society for Protective Coatings - Standards and Publications. (Accessed [Current Date, e.g., November 1, 2023])

- ISO (International Organization for Standardization) - Standards for Coatings. (Accessed [Current Date, e.g., November 1, 2023])

- ASTM International - Paint and Related Coatings Standards. (Accessed [Current Date, e.g., November 1, 2023])

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025