- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Steel Structure Maintenance Tips

Proper maintenance is essential for ensuring the longevity and safety of steel structure buildings. As leading steel building manufacturers, we at YEED TECH understand the importance of regular upkeep to preserve structural integrity. These maintenance tips will help you protect your investment in steel structure projects while maximizing their service life.

Regular Inspection of Steel Structure Buildings

• Schedule bi-annual visual inspections of all steel structure components

• Check for signs of corrosion, especially in joints and connections

• Monitor for any deformation or bending in structural members

• Examine paint and protective coatings for wear

• Look for cracks or fatigue in high-stress areas

Corrosion Protection for Steel Structures

• Apply high-quality protective coatings recommended by steel building manufacturers

• Consider galvanization for critical steel structure components

• Implement cathodic protection systems where needed

• Remove rust immediately using approved methods

• Maintain proper drainage to prevent water accumulation

Cleaning Procedures for Steel Structure Buildings

• Use mild detergents for routine steel structure cleaning

• Avoid abrasive materials that could damage protective coatings

• Remove dirt and debris from hard-to-reach areas

• Clean gutters and drainage systems regularly

• Pressure wash carefully following steel building manufacturers' guidelines

Preventive Maintenance from Steel Building Manufacturers

• Follow maintenance schedules provided by steel building manufacturers

• Tighten bolts and fasteners as needed

• Lubricate moving parts in steel structure assemblies

• Replace worn components before failure occurs

• Keep detailed maintenance records

Special Considerations for Steel Structure Buildings

• Monitor for thermal expansion effects

• Check fire protection systems regularly

• Inspect after extreme weather events

• Verify load capacities haven't been exceeded

• Update seismic retrofitting as needed

Steel Structure FAQs

Q: What are the key advantages of steel structure buildings compared to traditional concrete ones?

A: steel structure buildings offer several advantages over traditional concrete structures. They are lighter, reducing foundation costs and making them easier to transport and install. Construction is faster due to prefabricated components, cutting project timelines by 30–50%. Steel is highly durable, resistant to pests, rot, and fire (with proper coatings), and has better seismic performance, flexing without collapsing during earthquakes. Additionally, steel is 100% recyclable, aligning with sustainability goals, and allows for greater design flexibility, enabling larger open spaces and modular expansions.

Q: How to choose reliable steel building manufacturers?

A: To choose reliable steel building manufacturers, start by checking their industry experience and certifications (e.g., ISO, AISC) to ensure compliance with quality and safety standards. Review their portfolio of completed projects, especially those similar to your needs (e.g., commercial, industrial). Request references from past clients to assess satisfaction with delivery times, installation support, and after-sales service. Evaluate their production capabilities, including customization options and ability to meet deadlines. A reliable manufacturer will also offer clear warranties, transparent pricing, and technical assistance for design and installation.

Q: What factors affect the lifespan of a steel structure?

A: The lifespan of a steel structure depends on several factors. Corrosion is a primary concern—proper protective coatings (e.g., galvanization, paint) and regular maintenance can extend life to 50–100 years or more. Environmental conditions, such as high humidity, saltwater exposure (for coastal areas), or industrial pollutants, accelerate wear, requiring more frequent inspections. Load-bearing capacity and design quality also matter; structures built to withstand intended loads (without overloading) and with proper drainage systems to prevent water damage last longer. Regular maintenance, including rust removal and coating touch-ups, is key to maximizing lifespan.

Q: Are steel structure buildings suitable for residential use?

A: Yes, steel structure buildings are increasingly suitable for residential use. They offer design flexibility, allowing for open floor plans, large windows, and unique architectural features. Steel frames are lightweight yet strong, reducing foundation costs and enabling construction in areas with challenging soil conditions. They are also termite-resistant and fire-safe (with proper treatments), addressing common residential concerns. Prefabricated steel components speed up construction, minimizing on-site disruption. While initial costs may be slightly higher than wood, lower maintenance needs and longer lifespans make them cost-effective over time, appealing to eco-conscious homeowners.

Q: What customization options do steel building manufacturers typically offer?

A: steel building manufacturers offer diverse customization options to meet specific needs. They can tailor dimensions (height, width, length) to fit the intended use, whether a small garage or a large warehouse. Roof styles (gable, hip, sloped) and wall panel materials (metal, insulated, or custom cladding) are customizable for aesthetics and functionality. Additional features include windows, doors (roll-up, sliding, or personnel doors), skylights, and mezzanines for extra space. For industrial or commercial use, manufacturers can integrate crane systems, ventilation, or insulation for climate control. Many also offer custom color finishes to match brand or design requirements.

Welcome to Yeed Tech Co., Ltd. https://www.yeeeed.com/ – where steel meets smarts, and tradition gives way to innovation. As pioneers in intelligent steel structure solutions, we’re redefining what’s possible in cutting, forming, welding, and painting.

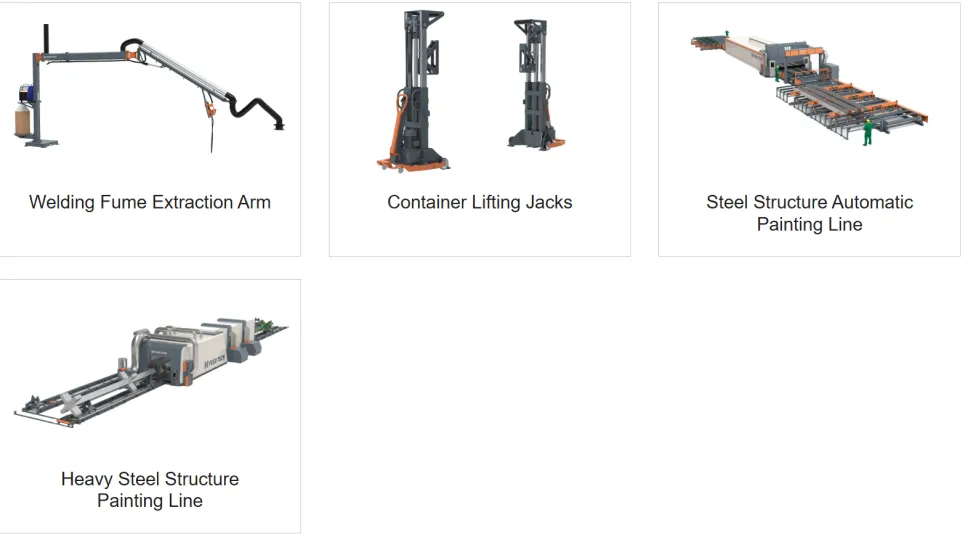

Our lineup – from smart spraying lines to high-power laser cutters, and welding arms to smoke control systems – isn’t just equipment. It’s a promise to replace manual labor with precision, safety with efficiency, and guesswork with automation.

Driven by our philosophy to boost steel structure processing intelligence, we blend R&D, production, and software into tools that transform workflows. Whether you’re scaling up or refining processes, we’re here to make your steel structures production smarter, smoother, stronger.

Step into the future of steel structure manufacturing. Your journey with YEED TECH starts now – where every machine is a step toward smarter production.

Products Categories

Latest News

-

Unveiling the World of Container Handling Equipment in the Marketplace

NewsAug.27,2025 -

Unlocking the Potential of Container Lifting Equipment

NewsAug.27,2025 -

Essential Equipment in Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Efficient Solutions for Shipping Container Manipulation

NewsAug.27,2025 -

Efficient Solutions for Container Handling: Equipment Insights

NewsAug.27,2025 -

Efficient Solutions for Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Welding Fume Composition Analysis

NewsAug.26,2025