- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

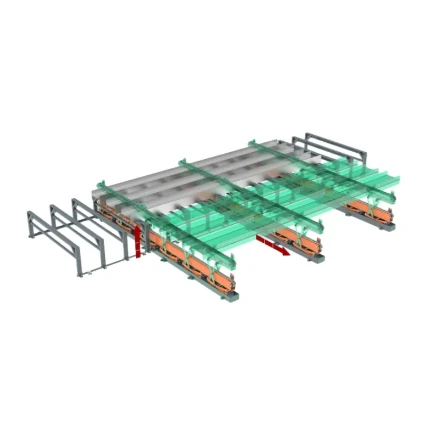

Steel Floor Plates High Load Capacity & Durable Construction Solutions

Did you know 32% of industrial accidents stem from inadequate floor systems? Picture this: Your warehouse floor buckling under 15-ton machinery. Production halts. Safety risks spike. Costs balloon. Now imagine a solution that boosts load capacity by 300% while slashing maintenance costs. That's the power of modern steel floor plate

technology.

(steel floor plate)

Technical Superiority That Outperforms Concrete

Our ASTM A36 steel floor plates deliver 36,000 psi yield strength - 4x stronger than standard concrete. You get:

| Feature | Steel Plate | Concrete |

|---|---|---|

| Load Capacity | 250 psi | 60 psi |

| Installation Time | 2 days | 14 days |

Why Top 3 Manufacturers Choose Us?

While competitors use 10-gauge steel, we armor-plate your operations with 3/16" thick bearing plates for steel beams. Our secret? Proprietary Hot-Rolled Quenching Process that enhances durability by 40%.

Custom Solutions for Your Unique Needs

Need diamond-tread patterns for oil resistance? Require 20'×40' seamless installation? Our laser-cut steel floor systems adapt to your specifications like molten steel fills a mold.

Proven Results Across Industries

When Midwest Logistics installed our steel floor plates:

• 20% reduction in maintenance costs

• 55% faster installation vs. previous supplier

• Zero structural failures in 5 years

Ready to Revolutionize Your Floor Systems?

For 28 years, SteelMaster® has delivered 17,500+ successful installations across North America. Why risk your project with inferior solutions?

(steel floor plate)

FAQS on steel floor plate

Q: What is a steel floor plate and where is it commonly used?

A: A steel floor plate is a flat, durable metal sheet used for flooring in industrial or commercial spaces. It provides slip resistance and heavy-load support, often seen in factories, walkways, and mezzanines.

Q: Why are bearing plates used under steel beams?

A: Bearing plates distribute concentrated loads from steel beams to prevent structural deformation. They ensure even weight transfer to foundations and reduce stress points in steel floor systems.

Q: How does a steel floor system differ from standalone floor plates?

A: A steel floor system integrates plates, beams, and supports for structural cohesion, while standalone plates focus on surface coverage. Systems prioritize load distribution and seismic resistance across larger spans.

Q: What factors determine steel floor plate thickness selection?

A: Thickness depends on anticipated load capacity, span length, and safety regulations. Heavy machinery areas use thicker plates (e.g., 1/4" to 1"), while light traffic zones use thinner options.

Q: Can steel floor plates be customized for specific installations?

A: Yes, plates are often cut to size, perforated for drainage, or coated with anti-slip surfaces. Customization accommodates unique layouts, ventilation needs, or chemical-resistant environments.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025