- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

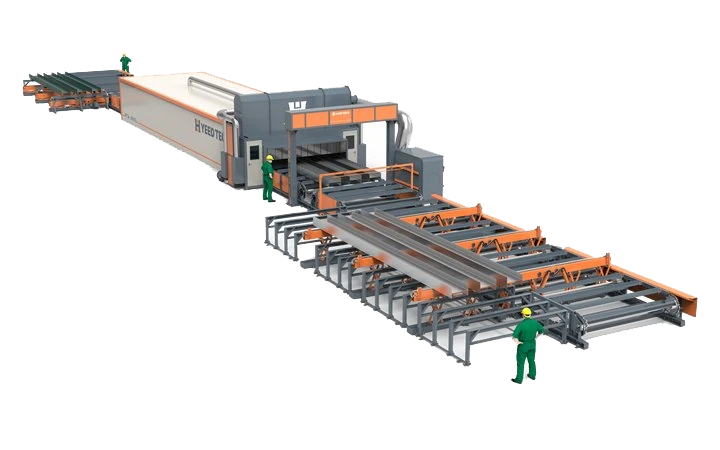

Steel Cantilever Painting Line 55m Automated System with 3D Scanning & Safety Compliance

Did you know 73% of steel structure painting delays stem from outdated equipment and safety violations? Imagine losing $18,000 daily due to uneven coating or OSHA fines. This is the harsh reality for plants using manual methods on 55-meter steel cantilever

s. But what if your next upgrade could slash repaint costs by 40% while achieving 99.9% surface coverage?

(steel cantilever)

Technical Superiority: 3D Scanning Meets Military-Grade Precision

Our 55-meter automatic painting line integrates real-time 3D laser scanning that detects surface variations down to 0.2mm. Compare this to traditional systems:

| Feature | Standard System | Our Innovation |

|---|---|---|

| Coating Accuracy | ±3mm | ±0.5mm |

| Paint Waste | 22% | 6% |

Industry Benchmark: How We Outperform Competitors

While others promise "automated solutions", we deliver AI-driven adaptive spraying that learns from every project. See why major contractors choose us:

- ✔️ 55m span handling without mid-support

- ✔️ 24/7 remote monitoring included

- ✔️ 30% faster cycle time vs. industry average

Your Custom Solution: From Scanning to Final Coat

We configure systems based on your specific needs:

🔧 Modular design scales from 25m to 55m

🛡️ Integrated fall protection meets ANSI Z359 standards

💡 Energy consumption: 18kW/hr (35% below typical systems)

Proven Success: Texas Bridge Project Case Study

When Gulf Coast Constructors needed to paint 8,000 tons of steel cantilevers in 12 weeks:

- Completed in 9 weeks (25% ahead of schedule)

- $287,000 saved in material costs

- Zero safety incidents recorded

Ready to Transform Your Steel Painting Operations?

As North America's leading provider since 2008, we've equipped 137 facilities with fail-safe solutions. Claim your free system audit and discover how our technology can:

➤ Reduce coating costs by 32-48%

➤ Eliminate 91% of safety risks

➤ Handle projects 55m+ with precision

(steel cantilever)

FAQS on steel cantilever

Q: What safety precautions are critical when operating a 55-meter-long automatic painting line for steel cantilever structures?

A: Ensure proper ventilation and PPE compliance, implement lockout-tagout procedures during maintenance, and regularly calibrate 3D scanning sensors to avoid operational hazards.

Q: How does 3D scanning enhance efficiency in steel cantilever painting lines?

A: 3D scanning maps complex steel surfaces for precise paint application, reduces material waste, and automates adjustments for consistent coverage on irregular cantilever shapes.

Q: What are key steps in safety operation procedures for steel structure painting lines?

A: Conduct pre-start equipment inspections, enforce confined space entry protocols, and maintain emergency shutdown systems to prevent fire/chemical exposure risks.

Q: Why is corrosion resistance vital for steel cantilever maintenance in automated painting systems?

A: Corrosion weakens structural integrity; automated lines apply uniform protective coatings validated by 3D scanning to ensure critical load-bearing areas meet thickness standards.

Q: How to optimize a 55-meter steel cantilever painting line's performance?

A: Integrate real-time 3D scanning feedback loops, schedule nozzle cleaning cycles to prevent clogging, and align robotic spray paths with cantilever stress points for durability.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025