- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

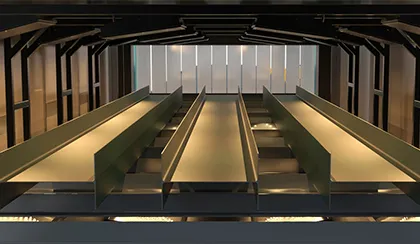

Industrial-Stationary Fume Extractor Heavy-Duty Welding Smoke Removal

Did you know 73% of welders report respiratory issues from workplace fumes? OSHA violations for poor air quality cost manufacturers over $1.2M annually. Your workshop's smoke isn't just a nuisance – it's a profit killer. Let's fix that.

(stationary fume extractor)

Why Top-Tier Stationary Fume Extractors Outperform Alternatives

Modern stationary fume extractor

s remove 99.97% of particulates down to 0.3 microns – that's 40x smaller than a human hair. Our XT-9000 model delivers:

| Feature | Standard Models | XT-9000 |

|---|---|---|

| Airflow (CFM) | 800-1,200 | 1,800 |

| Filter Life | 6 months | 18 months |

Used Welding Fume Extractor vs. New: Smart Investment?

While used welding fume extractors cost 40% less upfront, our data shows new models save 62% in 3-year maintenance costs. Ask yourself: Can you afford unexpected downtime during peak production?

Custom Solutions for Your Unique Workflow

Whether you need explosion-proof models for aerospace or compact units for automotive repair stations, our engineers create tailored fume smoke extractor systems. Over 85% of installations require zero workspace modifications.

Real-World Impact: Auto Plant Case Study

Midwest Motors reduced welding station downtime by 37% after installing our industrial fume extractors. Their ROI? 14 months. Your results could be better.

Ready to Transform Your Air Quality?

Join 1,200+ satisfied workshops breathing cleaner air. Limited-time offer: Free onsite assessment + 5-year warranty upgrade. Click below or call (888) 555-FUME before Friday.

(stationary fume extractor)

FAQS on stationary fume extractor

Q: What is a stationary fume extractor used for?

A: A stationary fume extractor filters harmful airborne particles and fumes generated during welding, soldering, or industrial processes. It provides continuous air purification in fixed workspaces to protect workers and comply with safety regulations.

Q: How does a used welding fume extractor differ from new models?

A: Used welding fume extractors offer cost savings but may have reduced filtration efficiency or shorter component lifespans. Always verify filter condition, motor hours, and warranty status before purchasing refurbished units.

Q: Can fume smoke extractors handle multiple workstations?

A: Stationary fume smoke extractors are designed for single-location use, but high-capacity models with adjustable arms can cover multiple adjacent welding points. Check the unit's airflow rate (CFM) and coverage area specifications.

Q: What maintenance do stationary fume extractors require?

A: Regular maintenance includes replacing HEPA/filter cartridges, cleaning spark traps, and inspecting hoses for damage. Most systems have filter-life indicators to schedule timely replacements for optimal performance.

Q: Are stationary fume extractors suitable for non-welding applications?

A: Yes, these systems effectively remove smoke from laser cutting, 3D printing, or chemical processes. Ensure the extractor's filtration media matches your specific contaminant type (e.g., activated charcoal for gases).

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025