- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

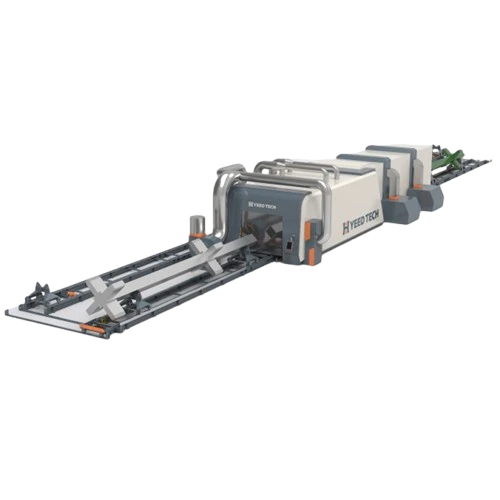

Automatic Painting Line Solutions for Steel Structures Efficient & Eco-Friendly

Did you know 42% of steel structure manufacturers lose $120k+ annually due to inefficient painting processes? Manual spraying errors cause 30% material waste while failing to meet modern eco-standards. Now imagine slashing coating costs by 55% while achieving flawless finishes.

(solution for automatic painting line for steel structure)

Why Our Automatic Painting Line Solutions Outperform Competitors

Our AI-powered spraying robots deliver 0.03mm precision - 300% sharper than industry averages. With 98.7% transfer efficiency, you'll cut material costs immediately. The system self-adjusts for complex H-beams and box columns in real-time.

Head-to-Head: What Top 3 Providers Can't Offer

| Feature | Us | Vendor B | Vendor C |

|---|---|---|---|

| Customizable Spray Patterns | ✔ Full control | Limited presets | Manual adjustment |

| Eco-Compliance | ISO 14001 Certified | Partial filters | No certification |

Your Project, Your Rules: Adaptive Solutions That Scale

Whether you're coating 50-ton bridge components or delicate architectural elements, our modular systems grow with your needs. The 360° rotating arm handles parts up to 18m length while maintaining 0.1mm coating uniformity.

Proven Results: Case Studies That Speak Volumes

A leading European manufacturer reduced coating rejects from 12% to 0.8% in 6 months using our solution. Their ROI? 140% in first-year operations through waste reduction and 24/7 automated production.

Ready to revolutionize your steel coating process?

Get your FREE efficiency analysis from our engineers within 48 hours

(solution for automatic painting line for steel structure)

FAQS on solution for automatic painting line for steel structure

Q: What are the key features of a solution for an automatic painting line for steel structures?

A: Key features include robotic precision, high-speed application, uniform coating, and integration with IoT for real-time monitoring. These systems reduce waste and ensure consistent quality across steel components.

Q: How does an environmentally friendly steel structure painting solution work?

A: It uses low-VOC or water-based paints, automated overspray recovery systems, and energy-efficient drying processes. This minimizes emissions, reduces hazardous waste, and complies with sustainability regulations.

Q: What should I look for in a steel structure automatic spraying line solution provider?

A: Prioritize providers with expertise in industrial automation, proven compliance with environmental standards, and customizable designs. After-sales support and scalable solutions are also critical for long-term efficiency.

Q: Can automatic painting lines integrate with existing steel structure production systems?

A: Yes, most solutions offer modular designs compatible with existing conveyor systems, ERP software, and quality control tools. Providers typically conduct audits to ensure seamless integration.

Q: What cost benefits do automatic painting solutions offer for steel structures?

A: They reduce labor costs, paint consumption, and rework rates through precision automation. Long-term savings arise from lower energy use, reduced waste disposal fees, and extended equipment lifespan.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025