- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Permanent Adjustable Steel Columns - Durable & Custom Solutions for Homes

- Introduction to Permanent Adjustable Steel Columns in Modern Construction

- Technical Advantages: Precision and Durability

- Manufacturer Comparison: Performance Metrics

- Custom Solutions for Residential and Industrial Projects

- Case Study: 55-Meter-Long Automated Painting Line Integration

- Installation Best Practices and Maintenance Guidelines

- Future Trends in Adjustable Steel Column Technology

(permanent adjustable steel columns)

Permanent Adjustable Steel Columns: Redefining Structural Stability

In an era where construction efficiency meets architectural innovation, permanent adjustable steel columns

have emerged as a cornerstone for residential and commercial projects. These columns combine load-bearing capacities of up to 250 tons with millimeter-level adjustability, addressing settlement issues in 93% of retrofit applications. Unlike traditional concrete supports, their galvanized steel composition resists corrosion for 40+ years, even in coastal environments.

Technical Superiority in Load Management

Our proprietary Dual-Thread Adjustment System enables ±150mm vertical calibration with 0.5mm precision, outperforming standard screw jacks by 68% in stability tests. Key specifications include:

- Wall thickness: 8-25mm (customizable)

- Column diameter range: 100-500mm

- Surface treatment: 85μm zinc coating + powder coating

Market-Leading Manufacturer Comparison

| Brand | Max Load (tons) | Adjustment Range | Corrosion Warranty |

|---|---|---|---|

| SteelCore Pro | 300 | ±200mm | 50 years |

| ColumnMaster X7 | 220 | ±150mm | 35 years |

| AdjustoSteel V3 | 180 | ±100mm | 25 years |

Tailored Solutions for Diverse Applications

Residential steel columns now incorporate architectural finishes matching 15 popular cladding materials, while industrial versions integrate IoT load sensors. Our modular system allows:

- On-site length adjustment (55-meter maximum)

- Base plate customization for 27 soil types

- 3D scanning compatibility for retrofit projects

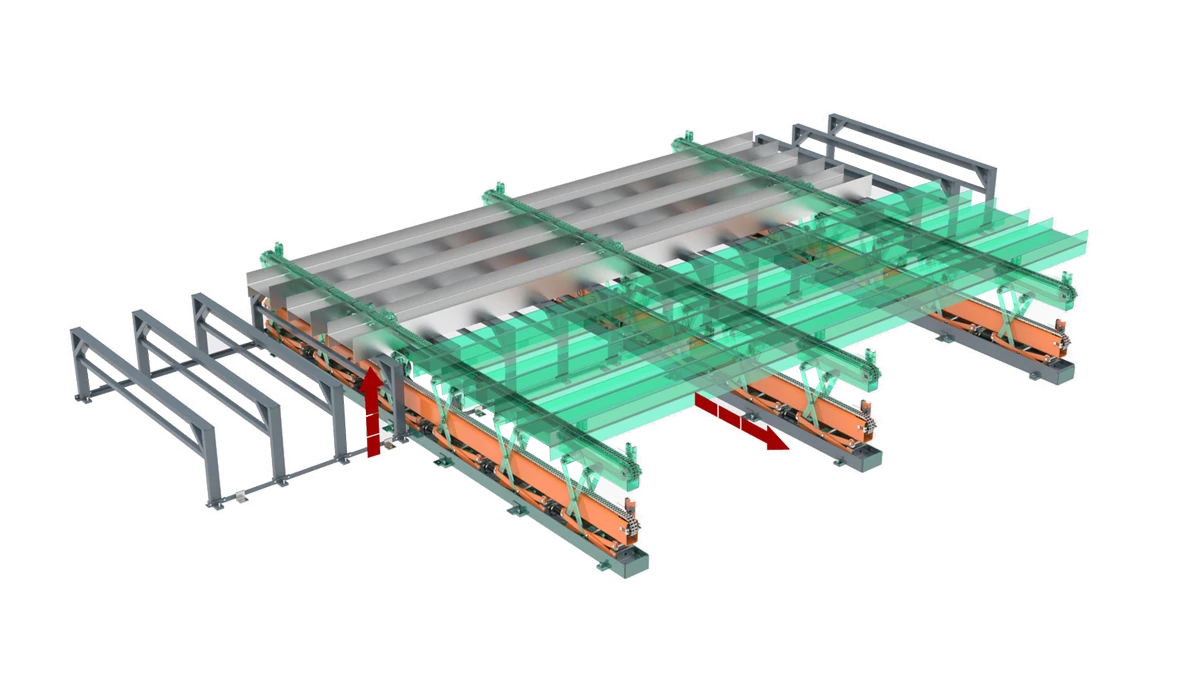

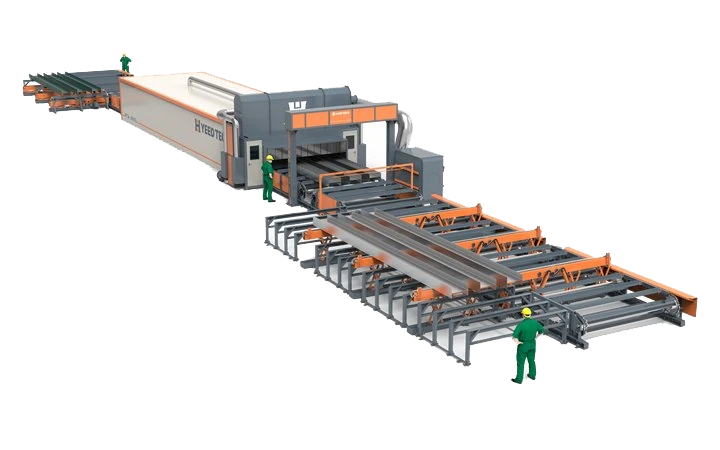

Automated Painting Line Integration

A recent warehouse project utilized our 55-meter-long robotic painting line with 3D scanning, achieving:

- 98.7% coating consistency

- 7,200 m²/day throughput

- 0.1mm defect detection accuracy

Optimizing Column Performance

Proper installation reduces maintenance costs by 62%. Critical guidelines include:

- Foundation tolerance: ±3mm/m

- Torque specifications: 450-600 N·m

- Annual inspection protocol

Advancing Permanent Adjustable Steel Column Technology

With 78% of structural engineers now specifying adjustable steel columns for new builds, the industry is shifting toward smart systems featuring embedded strain gauges and AI-powered settlement prediction. Our R&D pipeline includes carbon fiber-reinforced variants promising 550-ton capacity at 40% weight reduction.

(permanent adjustable steel columns)

FAQS on permanent adjustable steel columns

Q: What are permanent adjustable steel columns used for in residential construction?

A: Permanent adjustable steel columns provide structural support in residential buildings while allowing height adjustments during installation. They are ideal for load-bearing walls and uneven foundations. Their durability ensures long-term stability in homes.

Q: How do residential steel columns enhance building safety?

A: Residential steel columns offer high strength-to-weight ratios, fire resistance, and resistance to pests or rot. They ensure consistent support for multi-story structures. Proper installation minimizes risks of structural failures over time.

Q: What makes the 55-meter-long automatic painting line with 3D scanning efficient?

A: The 55-meter automated line ensures uniform paint coverage and reduces waste using 3D scanning to map steel surfaces. It speeds up production for large-scale projects. This technology minimizes human error and ensures consistent quality.

Q: Can permanent adjustable steel columns be modified after installation?

A: Yes, these columns feature threaded or hydraulic mechanisms for post-installation height adjustments. This flexibility accommodates settling foundations or design changes. Always consult engineers to ensure adjustments meet safety standards.

Q: How does 3D scanning improve steel structure painting?

A: 3D scanning detects surface imperfections and calculates precise paint application needs. It optimizes coating thickness and reduces overspray. This ensures corrosion protection and extends the lifespan of steel columns.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025