- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 19, 2025 02:10

Back To List

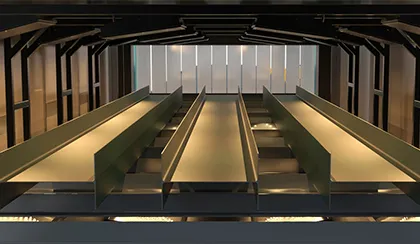

automated painting process

When investing in a spray paint machine, choosing one that integrates automation can be a game-changer for efficiency and finish quality. These automatic spray paint machines have revolutionized the industrial, automotive, and even artisanal painting sectors by providing consistent results and reducing the manpower traditionally required for painting tasks.

One often underestimated advantage of automated spray paint machines is their contribution to sustainability. With precise application, these machines reduce overspray and conserve paint, decreasing the environmental impact of painting activities. This aligns with increasing global demands for sustainable practices in manufacturing and other sectors. For those in the industrial sector considering the transition to automated spray painting, examining case studies can provide invaluable insights. For instance, a furniture manufacturer that recently transitioned to automatic spray machines reported a 30% increase in production capacity and a 15% reduction in paint usage within the first year of implementation. This case highlights not only the efficiency and precision of these machines but also their economic and environmental benefits. Choosing the right automatic spray painting machine requires understanding the specific needs of your operations. Factors such as the types of surfaces being painted, the volume of production, and the level of customization required will influence the decision-making process. Consulting with experts or conducting trials with multiple machines can prove beneficial. A trusted supplier who offers comprehensive support and training can add significant value, ensuring that your investment in automation results in optimal performance. In conclusion, an automatic spray paint machine is more than a purchase; it's a strategic investment in quality, efficiency, and sustainability. By adopting this technology, businesses not only improve their operational outcomes but also demonstrate a commitment to innovation and safety. As industries continue to evolve, automation represents a pivotal force in achieving excellence and maintaining competitive advantage in the marketplace.

One often underestimated advantage of automated spray paint machines is their contribution to sustainability. With precise application, these machines reduce overspray and conserve paint, decreasing the environmental impact of painting activities. This aligns with increasing global demands for sustainable practices in manufacturing and other sectors. For those in the industrial sector considering the transition to automated spray painting, examining case studies can provide invaluable insights. For instance, a furniture manufacturer that recently transitioned to automatic spray machines reported a 30% increase in production capacity and a 15% reduction in paint usage within the first year of implementation. This case highlights not only the efficiency and precision of these machines but also their economic and environmental benefits. Choosing the right automatic spray painting machine requires understanding the specific needs of your operations. Factors such as the types of surfaces being painted, the volume of production, and the level of customization required will influence the decision-making process. Consulting with experts or conducting trials with multiple machines can prove beneficial. A trusted supplier who offers comprehensive support and training can add significant value, ensuring that your investment in automation results in optimal performance. In conclusion, an automatic spray paint machine is more than a purchase; it's a strategic investment in quality, efficiency, and sustainability. By adopting this technology, businesses not only improve their operational outcomes but also demonstrate a commitment to innovation and safety. As industries continue to evolve, automation represents a pivotal force in achieving excellence and maintaining competitive advantage in the marketplace.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025