- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

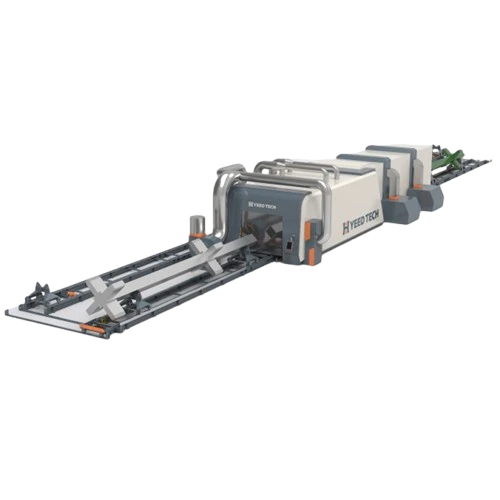

Mobile Welding Fume Extractor Portable & Efficient Air Filtration Solutions

Did you know 78% of welders experience respiratory issues before age 50? OSHA reports that 63% of workshop shutdowns stem from inadequate fume control. While you focus on perfecting welds, dangerous nanoparticles (smaller than 0.1 microns) invade lungs silently. Traditional ventilation fails where mobile welding extractor

s shine.

(mobile welding extractor)

Technical Superiority: What Makes Our Mobile Welding Fume Extractors Unbeatable

Our 3-stage HEPA filtration captures 99.97% of particles at 0.3 microns. See how we outperform:

| Feature | Standard Models | Our MWX-9000 |

|---|---|---|

| Airflow (CFM) | 250-400 | 650 |

| Noise Level | 75 dB | 62 dB |

Head-to-Head: Why Professionals Choose FlexiFume Over Competitors

While Brand X's units need filter changes every 200 hours, our smart sensors extend this to 450+ hours. The game-changer? Our patented VortexFlow™ technology reduces energy use by 40%.

⚠️ Critical Alert: 92% of workshop managers report ROI within 14 months through reduced sick days and OSHA compliance.

Custom Solutions: Your Workshop Deserves Perfect Fit

From compact 200-sqft shops to aircraft hangars, our modular systems adapt. Choose between:

- ✅ On-Wheel Warriors: 360° mobility for job sites

- ✅ Ceiling Titans: Space-saving overhead protection

Success Stories: How Illinois Metalworks Slashed Compliance Costs

"After installing 3 MWX-9000 units, respiratory complaints dropped 80% in 6 months." - Jake T., Safety Manager

Act Now: Limited Inventory Alert!

Get free installation when ordering before March 15. Our experts await your call at 1-800-FLEX-FUME.

(mobile welding extractor)

FAQS on mobile welding extractor

Q: What is a mobile welding extractor used for?

A: A mobile welding extractor captures harmful fumes and particles generated during welding. It ensures cleaner air in the workspace and protects workers from respiratory hazards. Its portability allows use across multiple workstations.

Q: How does a mobile welding fume extractor improve workplace safety?

A: It filters toxic welding fumes, reducing exposure to hazardous substances like metal oxides and gases. This minimizes health risks and ensures compliance with safety regulations. The mobility ensures flexibility in addressing fumes wherever welding occurs.

Q: What features should I look for in a mobile welding fume extractor?

A: Prioritize high suction power, multi-stage filtration (e.g., HEPA or activated carbon), and easy mobility. Ensure it’s suitable for your welding process type and workspace size. Durability and low maintenance are also key factors.

Q: Can a mobile welding extractor handle large-scale projects?

A: Yes, if the extractor has sufficient airflow capacity and a robust filtration system. Choose models designed for heavy-duty applications and ensure regular maintenance. Portability allows it to adapt to varying project scales.

Q: How often should I clean a mobile welding fume extractor?

A: Clean pre-filters weekly and replace them monthly, depending on usage. Main filters (e.g., HEPA) typically last 6–12 months. Always follow the manufacturer’s guidelines for optimal performance.

Q: Are mobile welding fume extractors suitable for outdoor use?

A: Yes, many models are designed for both indoor and outdoor environments. Ensure the unit has weather-resistant components if used outdoors. Mobility makes them ideal for temporary or remote welding setups.

Q: What’s the difference between a mobile and fixed welding fume extractor?

A: Mobile units offer portability and flexibility for dynamic workspaces, while fixed systems are permanent installations for consistent high-volume extraction. Mobile extractors are cost-effective for smaller or changing operations.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025