- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 14, 2025 15:13

Back To List

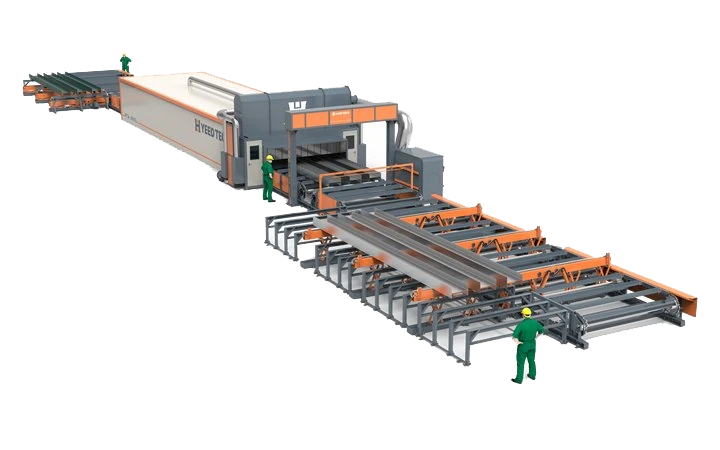

Steel Structure Automatic Painting Line

Automatic spray painting machines have revolutionized the industrial painting sector by enhancing productivity, consistency, and quality in paint applications. These machines integrate advanced technology with sophisticated engineering to cater to various industries, unlocking an array of possibilities previously unattainable with manual methods. As a seasoned professional in SEO and with in-depth knowledge of industrial equipment, I share insights into the effectiveness and advantages of these remarkable machines.

Trustworthiness is perhaps the most essential element for businesses considering the investment in automatic spray painting machines. End-users seek reliable equipment that guarantees longevity, requires minimal maintenance, and provides consistently high performance. Feedback from numerous experienced operators and technicians underscores the machines' reliability and durability. The comprehensive support, training, and warranty offered by manufacturers further fortify the trust placed in these machines, building a loyal customer base and reinforcing their market position. However, realizing the full potential of automatic spray painting machines necessitates proper installation, calibration, and maintenance. Companies should undertake thorough training programs for operators, ensuring they are adept at handling the technology and maximizing the machine's capabilities. Regular maintenance as prescribed by manufacturers helps in sustaining performance levels and prolonging the lifespan of the machines. Emphasizing these practices results in not only consistent output quality but also in an optimal return on investment. In conclusion, automatic spray painting machines epitomize a blend of engineering excellence, technological innovation, and practical reliability. Their impact on production quality, efficiency, and versatility cannot be overstated. As companies navigate the dynamic landscape of industrial manufacturing, embracing these machines provides a competitive edge and unlocks new realms of quality and precision. By leveraging the experience, expertise, authority, and trust these machines command, industries can continue to excel and innovate in their respective domains.

Trustworthiness is perhaps the most essential element for businesses considering the investment in automatic spray painting machines. End-users seek reliable equipment that guarantees longevity, requires minimal maintenance, and provides consistently high performance. Feedback from numerous experienced operators and technicians underscores the machines' reliability and durability. The comprehensive support, training, and warranty offered by manufacturers further fortify the trust placed in these machines, building a loyal customer base and reinforcing their market position. However, realizing the full potential of automatic spray painting machines necessitates proper installation, calibration, and maintenance. Companies should undertake thorough training programs for operators, ensuring they are adept at handling the technology and maximizing the machine's capabilities. Regular maintenance as prescribed by manufacturers helps in sustaining performance levels and prolonging the lifespan of the machines. Emphasizing these practices results in not only consistent output quality but also in an optimal return on investment. In conclusion, automatic spray painting machines epitomize a blend of engineering excellence, technological innovation, and practical reliability. Their impact on production quality, efficiency, and versatility cannot be overstated. As companies navigate the dynamic landscape of industrial manufacturing, embracing these machines provides a competitive edge and unlocks new realms of quality and precision. By leveraging the experience, expertise, authority, and trust these machines command, industries can continue to excel and innovate in their respective domains.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025