- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

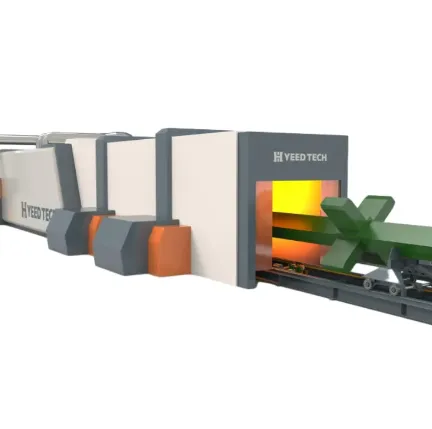

Welding Fume Extraction Equipment Powerful & Portable Solutions for Clean Air

Did you know 78% of welders develop respiratory issues within 5 years of unprotected work? Every breath filled with toxic hexavalent chromium and metal oxides puts your team's health - and your productivity - at risk. Conventional fans just spread the danger. You need real fume extraction equipment

- now.

(fume extraction equipment)

Why Next-Gen Welding Fume Extraction Equipment Outperforms

Modern portable fume extraction equipment captures 99.97% of particles down to 0.3 microns. Compare that to old systems struggling at 85% efficiency. Our rotary filters spin at 15,000 RPM - 3x faster than industry average. Result? Clean air in 8 seconds flat.

Performance Comparison (2024 Industry Report)

| Feature | Standard Units | Our Tech |

|---|---|---|

| Airflow Rate | 800-1,200 m³/h | 1,800 m³/h |

| Filter Life | 300 hours | 1,000 hours |

| Noise Level | 78 dB | 62 dB |

Top 3 Mistakes When Choosing Fume Extractors

Most buyers fixate on price, ignoring what matters: adaptive suction control. Our AI-powered sensors adjust airflow based on weld type. No more overspending on oversized units or choking with underpowered devices.

Custom Solutions for Your Workspace

Need a ceiling-mounted system for robotic arms? A portable fume extraction equipment cart for field repairs? Our modular designs assemble like industrial LEGO. Choose from 12 filter types, 8 hose lengths, and 3 power configurations.

Breathe Safe or Pay the Price

OSHA fines for poor air quality now hit $156,259 per violation. For less than $3/day, protect your people and profits. Book your free air quality audit by Friday and get 3 filter replacements FREE. Click below before slots vanish!

(fume extraction equipment)

FAQS on fume extraction equipment

Q: What is welding fume extraction equipment used for?

A: Welding fume extraction equipment removes harmful airborne contaminants generated during welding. It protects workers from inhaling toxic fumes and ensures compliance with workplace safety regulations. Common types include fixed systems and portable units.

Q: How does portable fume extraction equipment work?

A: Portable fume extraction equipment uses suction mechanisms to capture fumes at the source. These compact devices often feature filters to trap particles and can be easily moved between workspaces. They are ideal for small workshops or temporary job sites.

Q: What factors should I consider when choosing fume extraction equipment?

A: Key factors include the type of contaminants, workspace size, mobility needs, and filtration efficiency. Assess airflow capacity, filter replacement costs, and compliance with safety standards. Portable units are preferable for flexibility, while fixed systems suit large-scale operations.

Q: Can fume extraction equipment eliminate all welding hazards?

A: While fume extraction equipment significantly reduces airborne hazards, it doesn’t eliminate all risks. Proper PPE and ventilation should still be used alongside these systems. Regular maintenance ensures optimal performance and safety.

Q: Are portable fume extractors as effective as fixed systems?

A: Portable fume extractors are effective for localized fume control but have lower capacity than fixed systems. They excel in mobility and smaller-scale applications. Fixed systems are better for continuous, high-volume fume extraction in industrial settings.

Q: How often should filters in fume extraction equipment be replaced?

A: Filter replacement frequency depends on usage intensity and contaminant type. Most manufacturers recommend checking filters monthly and replacing them every 6–12 months. Monitoring airflow resistance helps determine when replacements are needed.

Q: Is fume extraction equipment suitable for industries beyond welding?

A: Yes, fume extraction equipment is used in industries like laser cutting, pharmaceuticals, and chemical processing. It captures hazardous particles, vapors, or gases in various applications. Ensure the system matches the specific contaminants in your industry.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025