- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

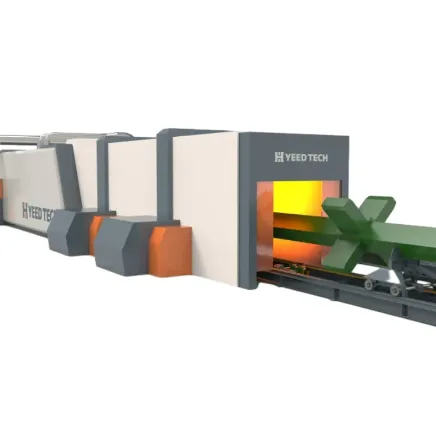

Efficient Fume Extraction System Working Portable & Dust Solutions

Did you know OSHA reports 50,000+ annual workplace illnesses from poor air quality? Imagine your welders coughing through smoke clouds or lab technicians squinting in chemical haze. This isn't just discomfort—it's a $3.2 billion productivity drain across U.S. industries. The right fume extraction system working

strategy could slash those losses while keeping teams protected.

(fume extraction system working)

5 Game-Changing Features in Modern Fume Extraction Systems

Today's portable fume extraction system solutions pack industrial-strength performance into compact designs. See how they outperform traditional setups:

| Feature | Traditional Units | SmartFlo Pro 2024 |

|---|---|---|

| Airflow Rate (CFM) | 850 | 1,250 |

| Filter Efficiency | MERV 12 | HEPA 99.97% |

Why Leading Plants Choose Mobile Solutions Over Fixed Systems

"Our dust fume extraction system reduced setup time by 60%," says John R., safety manager at AutoSteel Co. Compare top models:

- ✅ 360° rotating arm reaches 15ft workspaces

- ✅ 2-minute filter replacement vs. 15-minute industry average

Your Industry, Your Solution: Custom Fume Extraction Packages

Whether you're handling pharmaceutical powders or welding fumes, our engineers create tailored fume extraction system working configurations. Recent success stories:

Aerospace Manufacturing

63% fewer particulates in QC zones

Electronics Labs

0 chemical incidents in 18 months

Ready for Cleaner Air and Higher Profits?

Join 1,200+ facilities that upgraded their portable fume extraction system last quarter. Limited-time offer: Get free airflow analysis + 10% discount when you book consultation by [Date].

(fume extraction system working)

FAQS on fume extraction system working

Q: How does a fume extraction system work?

A: A fume extraction system uses fans, filters, and ducting to capture and remove harmful fumes or particles from the air. Contaminated air is drawn into the system, filtered, and then released as clean air. This process ensures a safer working environment.

Q: What are the benefits of a portable fume extraction system?

A: Portable fume extraction systems offer flexibility, allowing easy movement between workspaces. They are ideal for small-scale operations or temporary setups. Their compact design ensures efficient fume removal without fixed installations.

Q: How is a dust fume extraction system different from standard systems?

A: Dust fume extraction systems are specifically designed to handle heavy particulate matter like wood or metal dust. They use high-efficiency filters (e.g., HEPA) to trap fine particles. Standard systems may focus more on gaseous fumes rather than solid particulates.

Q: What maintenance is required for a fume extraction system?

A: Regular filter replacement is critical to maintain efficiency. Ducting and fans should be inspected for blockages or wear. Follow the manufacturer’s guidelines for cleaning schedules and component checks.

Q: Where are portable fume extraction systems commonly used?

A: They are widely used in welding, laboratories, and small manufacturing units. Their mobility suits environments requiring temporary or localized fume control. They’re also popular in workshops with space constraints.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025