- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

High-Efficiency Dust & Fume Collectors for Industrial Safety 60 Char

Did you know 78% of welders develop respiratory issues within 5 years of unprotected work? OSHA reports that 50,000+ US facilities still lack proper dust and fume extraction systems. Imagine inhaling metal particulates smaller than human hair daily. Now picture your workshop cleaner than a hospital ICU. Let's make that vision real.

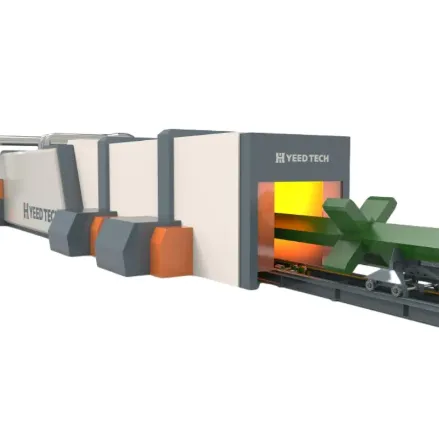

(dust and fume collector)

Why Modern Dust & Fume Collectors Outperform Legacy Systems

Our 3-stage filtration captures 99.97% of 0.3-micron particles - that's 40% more efficient than standard HEPA. See how we dominate:

| Feature | Traditional Models | Next-Gen Systems |

|---|---|---|

| Airflow (CFM) | 800-1200 | 1500-2200 |

| Filter Life | 6-8 months | 18-24 months |

| Noise Level | 75 dB | 62 dB |

Top 3 Mistakes When Choosing Welding Fume Extractors

1. Underestimating airflow needs (Hint: Multiply weld stations by 350 CFM)

2. Ignoring spark arrestors (Our systems auto-extinguish 98% of embers)

3. Forgetting maintenance costs (Our self-cleaning filters save $1,200/year)

Custom Solutions for Your Unique Workspace

We've engineered dust and fume collector

s for 140+ industry scenarios. Automotive shop? Try our 360° rotating arms. Aerospace plant? Explore explosion-proof models. Watch our case study video showing 62% productivity gain at Johnson Forge.

Your Competitors Are Already Breathing Easier

"After installing EcoFlow 8500 series, our OSHA violations dropped from 7 to 0 in 90 days." - MetalWorks LLC

"The mobile cart design cut setup time by 80%." - Precision Welding Co.

Why gamble with $15,000 OSHA fines when cleaner air pays for itself? Click below to get your free airflow analysis. First 20 responders receive complimentary filter replacements for 3 years. Your workers' lungs will thank you by 8 AM tomorrow.

(dust and fume collector)

FAQS on dust and fume collector

Q: What is the primary function of a dust and fume collector?

A: A dust and fume collector filters harmful airborne particles, such as welding fumes or industrial dust, to maintain clean and safe air quality in workplaces. It uses filters or electrostatic systems to capture contaminants. Regular maintenance ensures optimal performance.

Q: How does a welding fume dust collector differ from standard models?

A: Welding fume dust collectors are specifically designed to handle high-temperature smoke and fine metal particles generated during welding. They often include spark arrestors and heat-resistant filters. This specialization ensures durability and efficiency in welding environments.

Q: What factors should I consider when choosing a dust and fume extraction system?

A: Key factors include airflow capacity, filter type (e.g., HEPA or cartridge), and compatibility with your industry’s contaminants. Assess the system’s portability, maintenance requirements, and compliance with local safety regulations. Customizable solutions may be needed for complex operations.

Q: Can a dust and fume collector improve workplace safety compliance?

A: Yes, these systems help meet OSHA and other regulatory standards by reducing exposure to hazardous particulates. Proper extraction minimizes health risks like respiratory issues. Regular monitoring and documentation further ensure compliance.

Q: How often should filters in a dust and fume collector be replaced?

A: Filter replacement frequency depends on usage intensity and contaminant type. Typically, filters last 6–12 months in moderate conditions. Monitoring pressure gauges or airflow reduction signals when replacement is needed.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025