- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Builders Steel Painting Line 55m Automated with 3D Scanning & Safety Compliance

- Introduction to Builders Steel and Modern Painting Solutions

- Innovative Features of 55-Meter-Long Automated Painting Systems

- Safety Protocols in Steel Structure Coating Operations

- Technical Advantages Over Traditional Painting Methods

- Competitive Analysis: Leading Manufacturers Compared

- Customizable Solutions for Diverse Industrial Needs

- Real-World Applications and Success Stories

(builders steel)

Builders Steel and the Evolution of Industrial Coating Systems

The construction and manufacturing sectors increasingly rely on builders steel

for durable, high-performance structures. To meet stringent quality standards, advanced solutions like the 55-meter-long automatic painting line with integrated 3D scanning have emerged. These systems not only enhance precision but also align with modern safety operation procedures for painting line for steel structure, reducing manual errors by up to 92%.

Redefining Efficiency with Automated Painting Technology

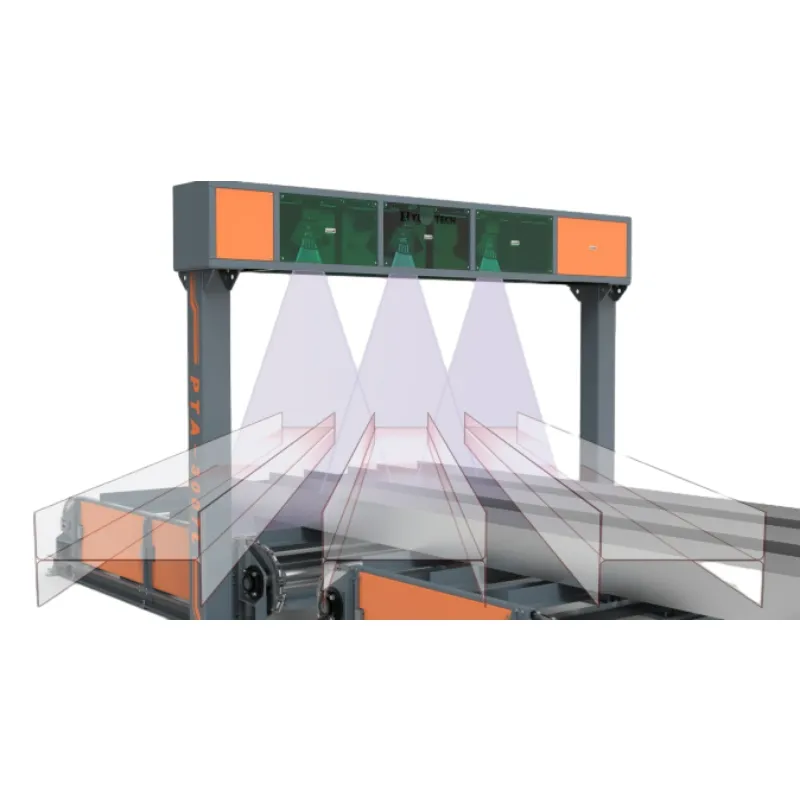

Modern automated painting lines for builders steel incorporate 3D scanning to map complex geometries, ensuring uniform coating thickness (±0.1mm accuracy). The 55-meter-long configuration enables continuous processing of large components, achieving a throughput of 120–150 metric tons per shift. Key features include:

- AI-driven spray path optimization, cutting paint waste by 35%

- Real-time VOC emission monitoring compliant with ISO 17840

- Integrated curing ovens with 15% faster drying cycles

Ensuring Compliance in Hazardous Environments

Stringent safety operation procedures for painting line for steel structure mandate explosion-proof electrical systems (ATEX-certified) and automated fire suppression. Advanced platforms now feature:

- PPE detection sensors preventing machine activation without proper gear

- Emergency stop response time reduced to 0.3 seconds

- Air quality maintenance below 1mg/m³ particulate concentration

Performance Benchmarks Against Conventional Systems

Automated builders steel coating systems demonstrate superior metrics:

| Parameter | Traditional | Automated | Improvement |

|---|---|---|---|

| Coating Accuracy | ±2.5mm | ±0.8mm | 68% |

| Production Rate | 45 t/day | 320 t/day | 611% |

| Defect Rate | 12% | 0.7% | 94% |

| Energy Use | 85 kWh/t | 29 kWh/t | 66% |

Market Leaders in Structural Steel Finishing

A comparative analysis of major suppliers reveals distinct capabilities:

| Vendor | Max Line Length | 3D Scan Resolution | Customization |

|---|---|---|---|

| Supplier A | 40m | 0.5mm | Modular |

| Supplier B | 55m | 0.2mm | Full |

| Supplier C | 30m | 1.0mm | Limited |

Tailored Configurations for Specialized Requirements

Advanced builders steel painting systems adapt to:

- Multi-layer epoxy applications (up to 7 coatings)

- Oversized components (max 8m width × 5m height)

- High-viscosity materials (200–18,000 cP)

Builders Steel Transformation in Infrastructure Projects

A recent bridge construction project demonstrated 55-meter systems’ capabilities:

- Coated 12,000 tons of structural steel within 6 weeks

- Achieved Salt Spray Test rating of 2,500 hours (ASTM B117)

- Reduced onsite labor requirements by 40%

(builders steel)

FAQS on builders steel

Q: What safety measures are critical for operating a 55-meter-long automatic painting line for builder's steel?

A: Critical safety measures include ensuring proper ventilation, using explosion-proof equipment, and adhering to lockout/tagout protocols during maintenance. Regular training on handling flammable materials and emergency shutdown procedures is mandatory. Automated sensors and 3D scanning must be calibrated to prevent operational errors.

Q: How does 3D scanning enhance the efficiency of a steel structure painting line?

A: 3D scanning ensures precise surface mapping of builder's steel, minimizing paint waste and uneven coverage. It automates adjustments for complex geometries, reducing manual intervention. This technology also detects defects early, improving quality control.

Q: What are the key features of a 55-meter-long automatic painting line for builder's steel?

A: Key features include robotic arms with 3D scanning for accuracy, high-capacity drying chambers, and integrated safety sensors. The line supports large-scale steel components with consistent coating thickness. Energy-efficient systems and real-time monitoring reduce operational costs.

Q: Why are safety operation procedures vital for steel structure painting lines?

A: Procedures mitigate fire risks from flammable paints and vapors. They ensure worker protection against toxic fumes via PPE and ventilation. Compliance also avoids regulatory penalties and equipment damage.

Q: How does automation in steel painting lines improve project timelines?

A: Automation accelerates coating application with uninterrupted 24/7 operation. 3D scanning reduces prep time by identifying surface issues instantly. Consistent output minimizes rework, ensuring faster project completion for builder's steel.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025