- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 16, 2025 01:15

Back To List

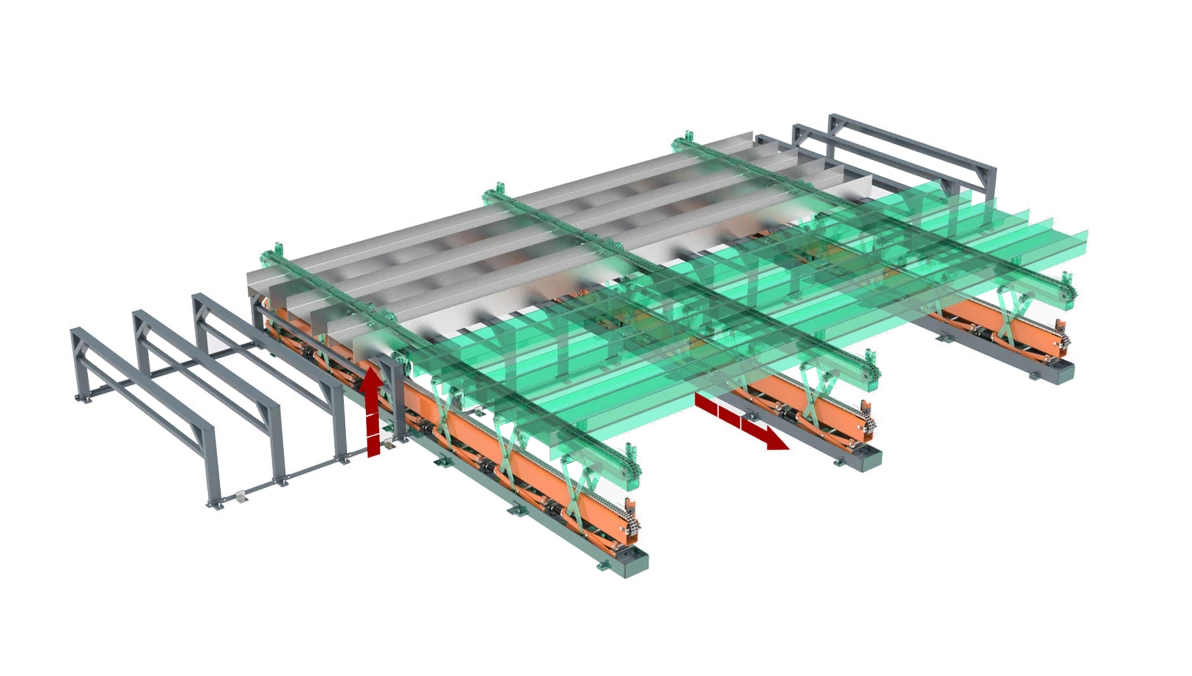

awtomatikong spray painting system na may conveyor

Revolutionizing industrial painting operations demands the integration of cutting-edge technology, and the automatic spray painting system with conveyor stands at the forefront of such innovation. With a seamless blend of experience, expertise, authoritativeness, and trustworthiness, these systems are redefining manufacturing efficiency and product finish quality.

Trustworthiness is a critical factor for industries that must ensure their output meets the highest quality standards. Automatic spray painting systems are revered for their reliability and precision. By providing consistent layer thickness and uniform application, these systems eliminate irregularities that could compromise the structural integrity or aesthetic appeal of products. This level of precision in application enhances the overall trust manufacturers—and ultimately, consumers—place in the finished products. Sustainability is another area where these systems excel. Equipped with advanced filtration and recovery systems, they drastically cut down on volatile organic compounds (VOCs) emissions and facilitate the recycling of excess paint. This eco-friendly approach not only aligns with global environmental standards but also projects a responsible corporate image for adopting companies. In summary, the automatic spray painting system with conveyor is a game-changer for industries aiming to elevate their production processes. By integrating these systems, manufacturers benefit from enhanced precision, reliability, and efficiency—cornerstones of competitive industrial operations. With proven experience, expert design, authoritative construction, and trusted performance, these systems are not just tools, but strategic assets in achieving superior production outcomes and sustainability goals. The adaptability and eco-conscious engineering further underscore their indispensability in modern manufacturing landscapes.

Trustworthiness is a critical factor for industries that must ensure their output meets the highest quality standards. Automatic spray painting systems are revered for their reliability and precision. By providing consistent layer thickness and uniform application, these systems eliminate irregularities that could compromise the structural integrity or aesthetic appeal of products. This level of precision in application enhances the overall trust manufacturers—and ultimately, consumers—place in the finished products. Sustainability is another area where these systems excel. Equipped with advanced filtration and recovery systems, they drastically cut down on volatile organic compounds (VOCs) emissions and facilitate the recycling of excess paint. This eco-friendly approach not only aligns with global environmental standards but also projects a responsible corporate image for adopting companies. In summary, the automatic spray painting system with conveyor is a game-changer for industries aiming to elevate their production processes. By integrating these systems, manufacturers benefit from enhanced precision, reliability, and efficiency—cornerstones of competitive industrial operations. With proven experience, expert design, authoritative construction, and trusted performance, these systems are not just tools, but strategic assets in achieving superior production outcomes and sustainability goals. The adaptability and eco-conscious engineering further underscore their indispensability in modern manufacturing landscapes.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025