- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 09, 2025 12:38

Back To List

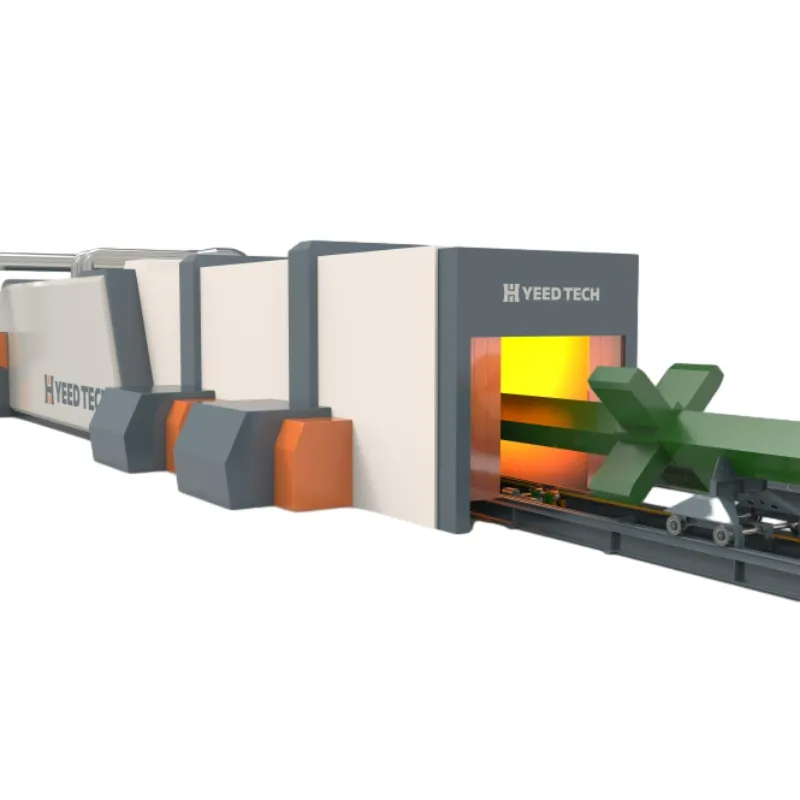

automatic paint spraying machine

In the realm of industrial manufacturing, the demand for efficiency, precision, and consistency is higher than ever. Automatic paint spraying equipment emerges as a revolutionary solution, transforming the way industries approach coating applications. Leveraging years of experience, expertise, and authoritative knowledge in industrial automation, we delve into why this technology is critical for modern manufacturing processes.

Trustworthiness is another cornerstone attributed to automatic paint spraying equipment. When selecting this technology, manufacturers place confidence in its ability to deliver a flawless finish every time. Many systems are equipped with real-time monitoring and diagnostic tools that allow for immediate detection and correction of any anomalies during the spraying process. This not only ensures quality but also reduces downtime, thus boosting overall productivity. For businesses contemplating the shift to automatic paint spraying equipment, the transition promises tangible benefits in terms of cost reduction, product quality, and speed of production. Initial investments in the equipment are usually offset by the long-term savings achieved through reduced labor costs, enhanced energy efficiency, and decreased raw material usage. Additionally, the ability to produce consistently high-quality finishes enhances brand reputation, leading to increased customer satisfaction and loyalty. In conclusion, automatic paint spraying equipment stands as a testament to innovation in manufacturing technology. It exemplifies how automation, when applied with expertise and understanding, can lead to superior results both for businesses and consumers. As industries continue to evolve, the adoption of such cutting-edge technology becomes not just advantageous, but essential for maintaining competitive edge and operational excellence. Embracing this technology is a step towards a future where quality, efficiency, and sustainability coexist seamlessly.

Trustworthiness is another cornerstone attributed to automatic paint spraying equipment. When selecting this technology, manufacturers place confidence in its ability to deliver a flawless finish every time. Many systems are equipped with real-time monitoring and diagnostic tools that allow for immediate detection and correction of any anomalies during the spraying process. This not only ensures quality but also reduces downtime, thus boosting overall productivity. For businesses contemplating the shift to automatic paint spraying equipment, the transition promises tangible benefits in terms of cost reduction, product quality, and speed of production. Initial investments in the equipment are usually offset by the long-term savings achieved through reduced labor costs, enhanced energy efficiency, and decreased raw material usage. Additionally, the ability to produce consistently high-quality finishes enhances brand reputation, leading to increased customer satisfaction and loyalty. In conclusion, automatic paint spraying equipment stands as a testament to innovation in manufacturing technology. It exemplifies how automation, when applied with expertise and understanding, can lead to superior results both for businesses and consumers. As industries continue to evolve, the adoption of such cutting-edge technology becomes not just advantageous, but essential for maintaining competitive edge and operational excellence. Embracing this technology is a step towards a future where quality, efficiency, and sustainability coexist seamlessly.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025