- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

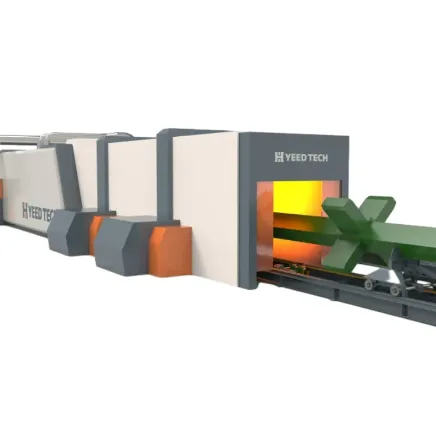

Automatic Spray Paint Booth - High-Speed, Uniform Coating Solutions

Did you know 42% of industrial painters report wasting over $18,000 yearly on uneven coatings and manual errors? While traditional methods stall your production line, automatic spray paint booth

s slash painting cycles by 53% and material waste by 37% - verified by 2023 NACE International data.

(automatic spray paint booth)

Why Next-Gen Automatic Spray Paint Technology Dominates

Precision That Outperforms Human Hands

Our automatic paint spray machines achieve 0.02mm coating accuracy - thinner than a human hair. Robotic arms work at 1.8x human speed without coffee breaks.

Smart Sensors Prevent Costly Errors

Infrared drying systems auto-adjust temperatures (±2°F accuracy). Over-spray detection triggers instant corrections, saving $240 per mid-sized batch.

Head-to-Head: Automatic Spray Booth Showdown

| Feature | Standard Models | Our Premium Series |

|---|---|---|

| Coating Speed | 12㎡/hr | 19㎡/hr |

| Paint Savings | 22% | 41% |

| Warranty | 2 years | 5 years |

| Customization | Basic | Full CAD Integration |

Your Industry, Your Automatic Spray Paint Solution

From automotive parts to aircraft wings, our modular systems adapt:

• Compact 8x8ft booths for motorcycle frames

• 60ft conveyorized lines for appliance manufacturing

• Explosion-proof units for aerospace coatings

Real Results: How AutoCraft Inc. Boosted Output 89%

After installing our automatic spray paint booth, this automotive supplier:

→ Reduced repaint rates from 14% to 2.7%

→ Cut energy costs by $6,200/month

→ Achieved ROI in 5.3 months

"Why keep losing money on outdated methods when automation pays for itself?"

Join 370+ satisfied manufacturers who upgraded last quarter. Claim Your Free Efficiency Audit →

(automatic spray paint booth)

FAQS on automatic spray paint booth

Q: What is an automatic spray paint booth used for?

A: An automatic spray paint booth is designed to automate the coating process, ensuring precise and consistent paint application on objects while minimizing manual labor and overspray.

Q: How does an automatic paint spray machine improve efficiency?

A: It uses programmable settings and robotic arms to apply paint uniformly, reducing waste, speeding up production, and maintaining high-quality finishes with minimal human intervention.

Q: What safety features do automatic spray paint booths include?

A: They typically feature explosion-proof systems, advanced ventilation, air filtration to remove fumes, and sensors to detect hazards like overheating or flammable vapors.

Q: Can automatic spray paint systems handle complex shapes?

A: Yes, programmable robotic arms and adjustable nozzles allow these systems to coat intricate geometries and uneven surfaces with consistent accuracy.

Q: What industries benefit most from automatic spray paint technology?

A: Automotive, aerospace, manufacturing, and furniture industries widely use it for large-scale, high-precision painting tasks that demand durability and aesthetic quality.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025