- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

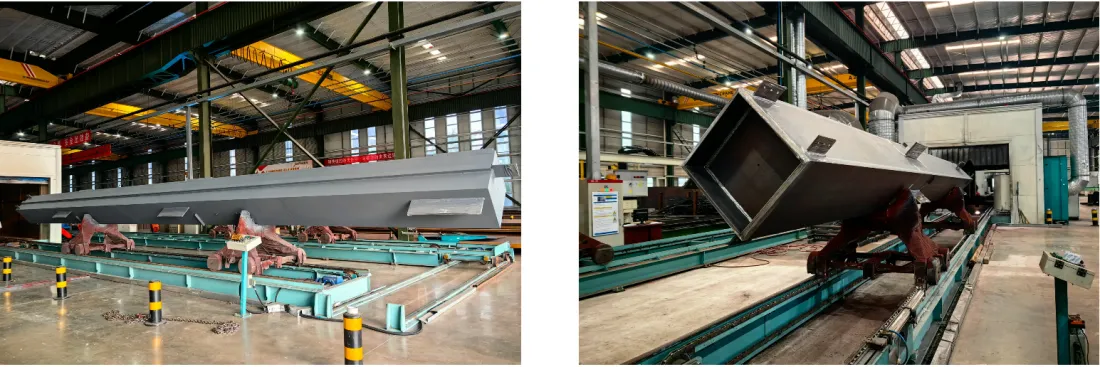

Automatic Painting Machine for Steel Structure Compatibility

The modern industrial painting landscape demands perfect harmony between automated spray coating systems, Automatic Painting Machine for Steel Structures, and Automatic Painting Machine for Steel Structure. At YEED TECH, we specialize in creating seamless integration solutions that maximize efficiency and quality in steel component finishing applications.

Automated Spray Coating Systems Integration

• Advanced communication protocols ensure automated spray coating systems operate flawlessly

• Precision calibration maintains consistent performance across all components

• Intelligent synchronization with conveyor speeds up to 20 fpm

• Real-time feedback mechanisms optimize coating quality

• Comprehensive error detection minimizes production downtime

Automatic Painting Machine for Steel Structure Performance

• Automatic Painting Machine for Steel Structures handle viscosities from 50-500 cP

• Operating pressures between 1000-3000 psi ensure optimal flow

• Multiple nozzle sizes (0.011"-0.021") accommodate different materials

• Built-in temperature compensation (50-120°F) maintains consistency

• Broad compatibility with industrial coating formulations

Automatic Paint Spraying Equipment Features

• Automatic paint spraying equipment incorporates progressive cavity pumps

• 100 micron filtration protects system integrity

• Heated circulation maintains perfect material viscosity

• Automated flushing enables quick color changes

• Ergonomic design simplifies maintenance access

System Control Capabilities

• Automated spray coating systems feature intuitive PLC interfaces

• Advanced recipe management stores 500+ formulations

• Multi-level access control ensures operational security

• Cloud-based data logging enables performance tracking

• Remote diagnostics facilitate quick troubleshooting

Maintenance Requirements

• Automatic Painting Machine for Steel Structures require daily cleaning cycles

• Weekly calibration maintains ±0.5% accuracy

• Quarterly replacement of wear parts prevents failures

• Annual lubrication extends mechanical lifespan

• Bi-annual software updates deliver new features

Automated Spray Coating Systems FAQs

Q: How to maintain an Automatic Painting Machine for Steel Structure for consistent performance?

A: To maintain an Automatic Painting Machine for Steel Structure for consistent performance, regularly clean the dispensing nozzles and hoses to prevent clogs from dried paint. Calibrate the machine weekly using manufacturer guidelines to ensure accurate paint volume and mixing ratios. Check seals and gaskets for wear, replacing them promptly to avoid leaks. Use filtered paint to prevent debris from damaging internal components. Store the dispenser in a clean, temperature-controlled area to protect electronic parts, and follow the supplier’s recommended schedule for lubricating moving parts. Regular software updates (for digital models) also help optimize functionality.

Q: What safety features should automatic paint spraying equipment include?

A: automatic paint spraying equipment should include key safety features to protect operators and workspaces. These include emergency stop buttons to halt operation instantly, overspray containment systems (like booths or shields) to limit exposure to fumes, and ventilation systems to remove volatile organic compounds (VOCs). Many models have pressure sensors to prevent over-pressurization, and interlocks that disable the sprayer if safety doors are open. For industrial use, flame-retardant materials and spark-resistant components reduce fire risks, especially when using flammable paints. Operator training on safety protocols is also critical to maximize these features.

Q: What industries benefit most from automated spray coating systems?

A: automated spray coating systems benefit several industries, particularly those requiring precision and consistency. Automotive manufacturing uses them for uniform vehicle body coatings, reducing overspray and material waste. Aerospace relies on them for applying protective finishes to aircraft parts with strict thickness requirements. Furniture and woodworking industries leverage their ability to coat large surfaces (like tables or cabinets) evenly. Electronics manufacturing uses automated systems for delicate component coating, ensuring insulation and corrosion resistance. Additionally, metal fabrication, appliance production, and even medical device manufacturing benefit from the efficiency and repeatability of these systems.

Q: Can an Automatic Painting Machine for Steel Structure handle different types of paint?

A: Yes, most Automatic Painting Machine for Steel Structure models can handle different types of paint, though compatibility depends on the machine’s design. Water-based paints, solvent-based paints, enamels, and lacquers are generally manageable with proper cleaning between uses. Some dispensers are specifically designed for thick materials like primers or textured paints, featuring powerful pumps and larger nozzles. It’s important to check the manufacturer’s guidelines—for example, high-viscosity paints may require heated reservoirs to maintain flow, while two-part epoxy paints need mixing mechanisms to prevent curing in the machine. Using compatible cleaning solvents after each use prevents cross-contamination and ensures the dispenser works reliably across paint types.

Q: How does the cost of automatic paint spraying equipment compare to manual spraying?

A: automatic paint spraying equipment has a higher upfront cost than manual tools, with industrial models ranging from several thousand to tens of thousands of dollars, compared to a few hundred for manual sprayers. However, long-term savings are significant: automatic systems reduce paint waste by 30–50% through precise application, lower labor costs by minimizing operator time, and improve consistency, reducing rework expenses. They also boost production speed, handling more parts per hour than manual spraying. For high-volume operations (e.g., manufacturing lines), the return on investment (ROI) typically occurs within 1–3 years, making them cost-effective for businesses with steady production needs.

Welcome to Yeed Tech Co., Ltd. https://www.yeeeed.com/ – where steel meets smarts, and tradition gives way to innovation. As pioneers in intelligent steel structure solutions, we’re redefining what’s possible in cutting, forming, welding, and painting.

Products Categories

Latest News

-

Unveiling the World of Container Handling Equipment in the Marketplace

NewsAug.27,2025 -

Unlocking the Potential of Container Lifting Equipment

NewsAug.27,2025 -

Essential Equipment in Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Efficient Solutions for Shipping Container Manipulation

NewsAug.27,2025 -

Efficient Solutions for Container Handling: Equipment Insights

NewsAug.27,2025 -

Efficient Solutions for Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Welding Fume Composition Analysis

NewsAug.26,2025