- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Automatic Paint Spraying Machine: Precision Coating Solution

Industry Evolution: Growth of Automated Painting Solutions

The industrial painting sector has undergone remarkable evolution in the past decade, largely driven by advancements in automation technology. According to the International Journal of Coatings Technology, global adoption of automatic paint spraying machines has grown by over 150% since 2015, with projections indicating continued growth at 12% CAGR through 2030. This transformation is fueled by several key factors:

Automated painting processes deliver unprecedented consistency compared to manual applications. Studies published in the Journal of Industrial Engineering reveal that automated systems achieve coating uniformity variances below 2.5%, compared to 15-30% variations common with manual spraying. This consistency directly impacts product quality while reducing material waste by up to 45%.

Environmental compliance has also become a significant driver in the adoption of automatic spray painting systems. Modern systems feature advanced overspray capture technologies with 98.5% efficiency rates, dramatically reducing VOC emissions while improving workplace safety. Additionally, computerized fluid management systems optimize paint usage, contributing to substantial environmental and cost benefits.

Technological Breakthroughs in Robotic Painting

Several recent technological advancements have expanded the capabilities of automatic paint dispensing equipment:

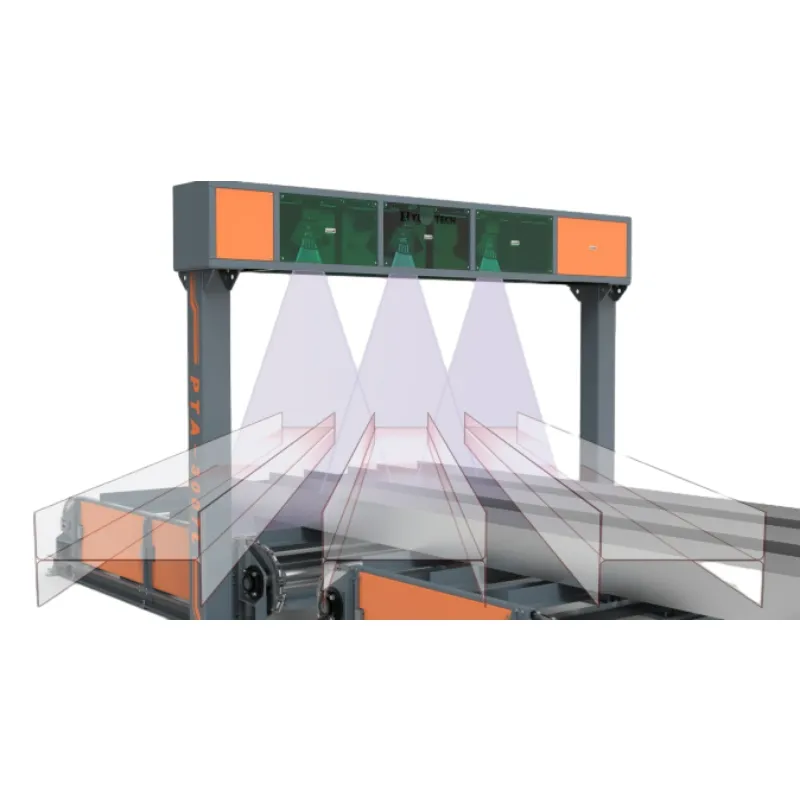

Smart Sensing Technology: Integrated vision systems and 3D scanning create virtual maps of complex surfaces with sub-millimeter precision, enabling uniform application even on irregular geometries.

Predictive Maintenance Systems: IoT-enabled sensors monitor component health and utilization patterns, scheduling maintenance before failures occur and reducing downtime by up to 30%.

Adaptive Control Algorithms: Machine learning algorithms continuously optimize application parameters (pressure, distance, flow rate) based on environmental conditions and surface characteristics.

These innovations in automatic paint spraying machines enable manufacturers to achieve complex finishing specifications with increased repeatability and efficiency.

Technical Specifications of Modern Spraying Systems

Contemporary automatic spray painting systems incorporate sophisticated technical specifications that set them apart from previous generations. These parameters are critical in determining system capabilities and suitability for different industrial applications.

| Technical Parameter | Standard Range | High-Performance Systems | Application Significance |

|---|---|---|---|

| Application Precision | ±0.5 mm | ±0.1 mm | Critical for complex geometries and tight tolerance applications |

| Maximum Throughput | 200-300 sq. ft./hr | 600-800 sq. ft./hr | Determines production capacity for large projects |

| Pressure Control Range | 10-60 psi | 5-100 psi | Allows optimization for different coating viscosities |

| Positioning Repeatability | ±0.3 mm | ±0.05 mm | Essential for consistent coverage and edge definition |

| Fluid Delivery Accuracy | ±3% | ±0.5% | Impacts material usage efficiency and coating uniformity |

| Multi-Axis Movement | 4-6 axes | 7-9 axes | Enables complex surface coverage without repositioning |

The evolution in key metrics of automatic paint dispensing technology over the past decade reveals steady improvement in capabilities that drive efficiency and quality.

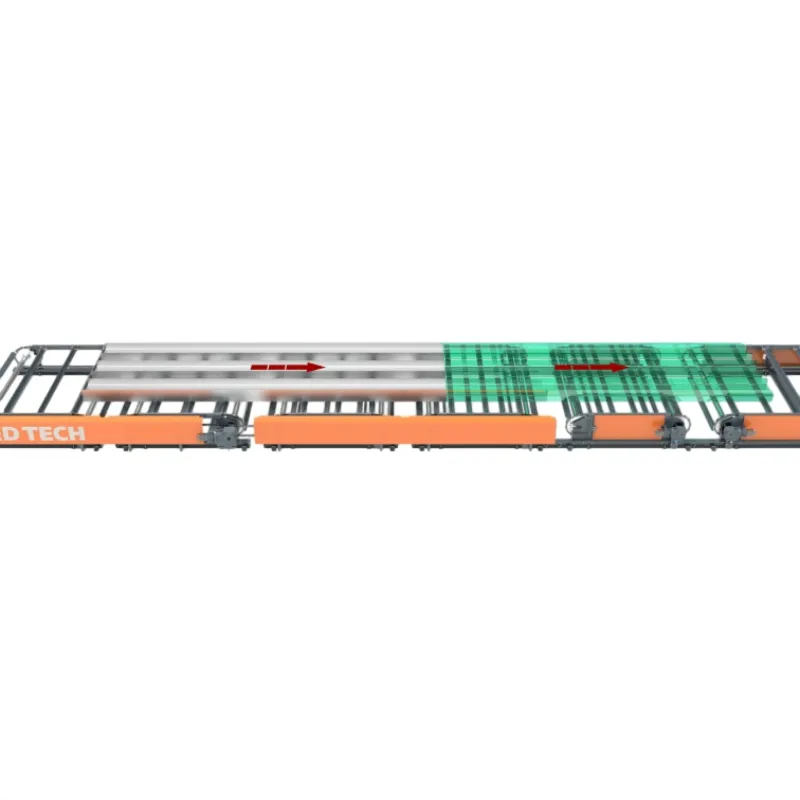

Yeed Tech's Innovative Steel Structure Painting Line

Yeed Tech Co.,Ltd. has pioneered the industry-leading Steel Structure Automatic Painting Line, which sets new standards for efficiency, safety, and precision in industrial coating applications. This advanced system addresses critical challenges in large-scale structural painting operations.

Key Innovation: Patented scissor lift design with exceptional 3.5T single load-bearing capacity enables the painting of oversized structural elements while maintaining dimensional stability during operation.

Smart Synchronization: The system features adaptive speed regulation that automatically adjusts conveyor velocity based on real-time spraying dynamics and sensor inputs, optimizing production flow.

Enhanced Safety Architecture

Beyond its production capabilities, Yeed Tech's solution integrates comprehensive safety protocols:

- Advanced proximity sensors prevent collision between components and critical mechanisms

- Multi-stage overspray containment system with active filtration

- Dual-layer emergency stop systems with integrated position memory

- Real-time environmental monitoring for ventilation and vapor management

Discover our revolutionary painting solution: Steel Structure Automatic Painting Line

Contact Yeed Tech Co.,Ltd.

Website: www.yeeeed.com

Phone: +86 181 0328 1106

Mobile: +86 18103281106

Email: yeed@yeed-tech.com

Address: No.28, Wei’Er Road, Anping County, Hebei Province, China

Advanced Applications Across Industries

The versatility of modern automatic paint spraying machines enables deployment across diverse industrial sectors with significantly improved outcomes:

Construction & Infrastructure

The demanding requirements of structural steel coating make it ideal for automated solutions. Automatic spray painting systems ensure uniform protective coatings on I-beams, trusses, and connections, with production speeds increased by 300% compared to manual methods. Their robotic precision consistently achieves critical thickness specifications necessary for corrosion protection in challenging environments.

Automotive Manufacturing

Modern automotive plants utilize sophisticated automated painting processes to maintain strict quality standards across high-volume production lines. These systems can apply multiple coating layers (primer, basecoat, clearcoat) with micron-level precision while achieving up to 98% material transfer efficiency—significantly reducing waste compared to conventional spray booths.

Aerospace Applications

The aerospace industry relies on precision coating applications using specialized automatic paint dispensers capable of handling complex contours with stringent weight constraints. These systems apply specialized aircraft coatings with accuracy better than ±5 microns while maintaining consistent finish quality across large surface areas like wings and fuselage sections.

According to Aviation Technology Today, airlines implementing advanced automatic paint spraying machines have reduced aircraft recoating cycles from 7-10 days to less than 72 hours, representing significant operational cost savings.

Professional FAQ: Automatic Painting Systems Explained

Comprehensive safety certification is critical for industrial painting automation. Required certifications include:

- ISO 10218 (Robotic Safety Standards)

- ATEX Zone 1/Zone 21 (Explosive Atmosphere Compliance)

- NFPA 33 Spray Application Standards

- CE Machinery Directive 2006/42/EC

- OSHA 1910.94 Ventilation Requirements

Yeed Tech systems incorporate multiple layers of safety including SICK safety scanners, emergency stop circuits, and hazardous area classification engineering that exceed these requirements.

Contemporary automatic spray painting systems utilize a multi-technology approach for film thickness management:

- Inline viscosity monitoring with closed-loop feedback

- Electrostatic application technology

- Ultrasonic film thickness measurement every 0.8 seconds

- Adaptive pressure/flow control algorithms

- Distance compensation using 3D surface mapping

This integrated system provides film thickness control of ±1 micron for critical applications.

Modern automatic paint spraying machines deliver significant ecological advantages:

- Reduced VOC emissions by 30-50% through optimized transfer efficiency

- Airborne particulate reduction by 85-95% with advanced filtration

- 40% reduction in coating waste compared to manual methods

- Water-based coatings compatibility reducing solvent consumption

- Energy efficiency improvements of 25% through process optimization

These advancements contribute directly to achieving sustainability goals in manufacturing environments.

Professional-grade automatic paint dispensers require structured maintenance protocols:

| Component | Daily Maintenance | Monthly Maintenance | Annual Service |

|---|---|---|---|

| Nozzles & Caps | Cleaning | Replacement | Full calibration |

| Fluid Path | Flushing | Pressure testing | Component replacement |

| Robotic Arms | Visual inspection | Greasing | Axis calibration |

| Control System | Software backups | Firmware updates | Electrical testing |

Yeed Tech systems feature diagnostic software that automatically logs 15+ operational parameters to predict maintenance needs before failures occur.

Modern solutions utilize multiple integrated technologies to address complex contours:

- Laser scanning creates point cloud models with ±0.1mm precision

- 7-axis robots provide extended articulation

- Motion synchronization maintains optimal spraying distance

- Path planning software simulates robotic movements

- Intelligent edge detection algorithms

These systems can automatically process components ranging from small brackets to entire bridge sections with minimum programming requirements.

The return on investment calculation for industrial automation considers:

- Labor Cost Reduction: 60-75% decrease versus manual operations

- Paint Savings: 30-40% reduction in material consumption

- Rejection Rate Improvement: 3-5% quality cost reduction

- Throughput Increase: 200-300% production capacity increase

- Reduced Environmental Fees: 25-35% lower regulatory costs

Typical ROI periods range from 14-28 months depending on production volume and coating requirements.

The integration of Internet of Things technologies has revolutionized painting automation:

- Real-time monitoring of 80+ operational parameters

- Predictive maintenance alerts for 95% of component failures

- Remote diagnostics capability with augmented reality overlays

- Energy consumption optimization algorithms

- Cloud-based recipe management systems

- Digital twin simulation for process optimization

These advancements provide unprecedented transparency into manufacturing processes while improving overall equipment effectiveness by up to 35%.

Future Innovations in Industrial Coating Technology

The next generation of automatic spray painting systems promises revolutionary capabilities through several developing technologies:

Nanotechnology Coatings

Advanced automated painting processes will accommodate increasingly sophisticated coating chemistries including nanocomposites that offer extraordinary protective capabilities. Equipment adaptations include nanoparticle agitation systems, specialized application heads, and precision layer control under 1 micron.

Artificial Intelligence in Process Optimization

AI-powered vision systems and machine learning algorithms will transform how automatic paint dispensing equipment operates. These systems will continuously improve application patterns based on quality feedback, optimizing over 100 parameters simultaneously to achieve unprecedented efficiency and quality levels.

Sustainability Developments: Future painting automation will feature closed-loop recycling systems achieving 99% solvent recovery, water-based coating innovations with near-zero VOC emissions, and energy regenerative technologies that capture kinetic energy from robotic movements.

Industry experts anticipate that these advancements will help automatic paint spraying machines reduce environmental impact by 65% while increasing production efficiency by 45% in the next decade.

Technical References & Industry Publications

1. Journal of Coatings Technology Research: "Advances in Robotic Finishing: Precision Analysis of Automated Spray Systems"

2. Industrial Automation Review: "Environmental Impact Assessment of Modern Painting Automation Technologies"

3. International Robotics Association: "Global Implementation Trends in Painting Robotics 2020-2030"

4. Surface Engineering Journal: "Materials Compatibility with High-Speed Application Systems"

5. Advanced Manufacturing Institute: "ROI Analysis of Painting Automation in Structural Fabrication"

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025