- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Automatic Paint Spraying Machine for Efficient Painting Solutions

As manufacturing demands increase for precision, efficiency, and sustainability, the automatic paint spraying machine has emerged as a cornerstone in modern coating and finishing lines. From automotive and construction machinery to petrochemical pipelines and structural steel, automated painting solutions like automatic paint dispensers and integrated automatic spray painting systems are setting new standards globally.

- Market Growth: According to MarketsAndMarkets, the global automated painting system market size surpassed $2.7 billion in 2023, projected to grow at a CAGR of 7.2% through 2028.

- Adoption Hotspots: Over 65% of heavy engineering factories in China utilize automated processes for corrosion-resistant coatings.

- Key Advancements: Integration with Industrial IoT, AI-driven spray path optimization, and ANSI/ISO-based coating quality analytics.

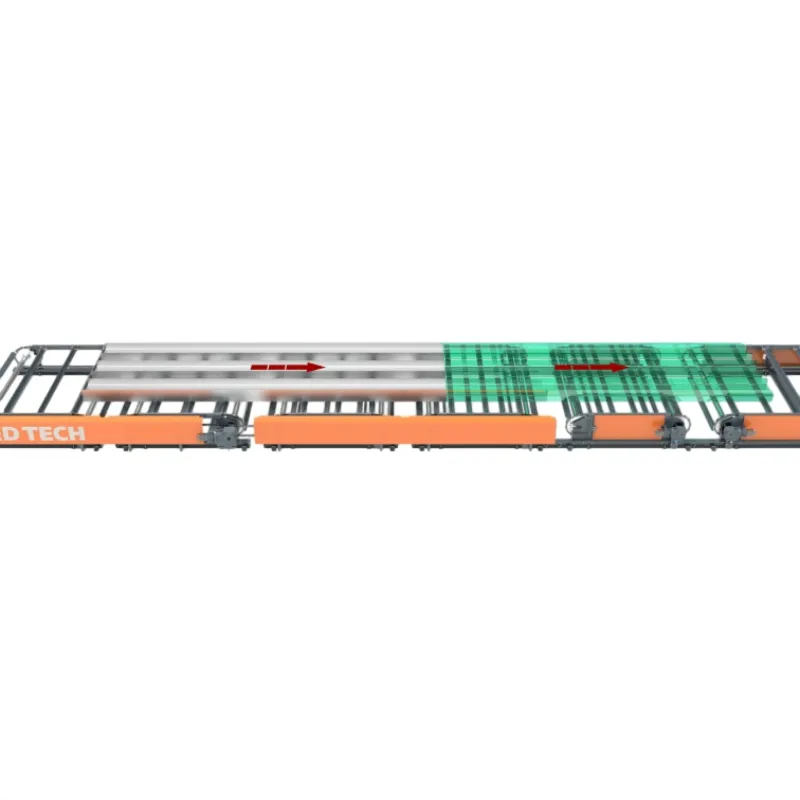

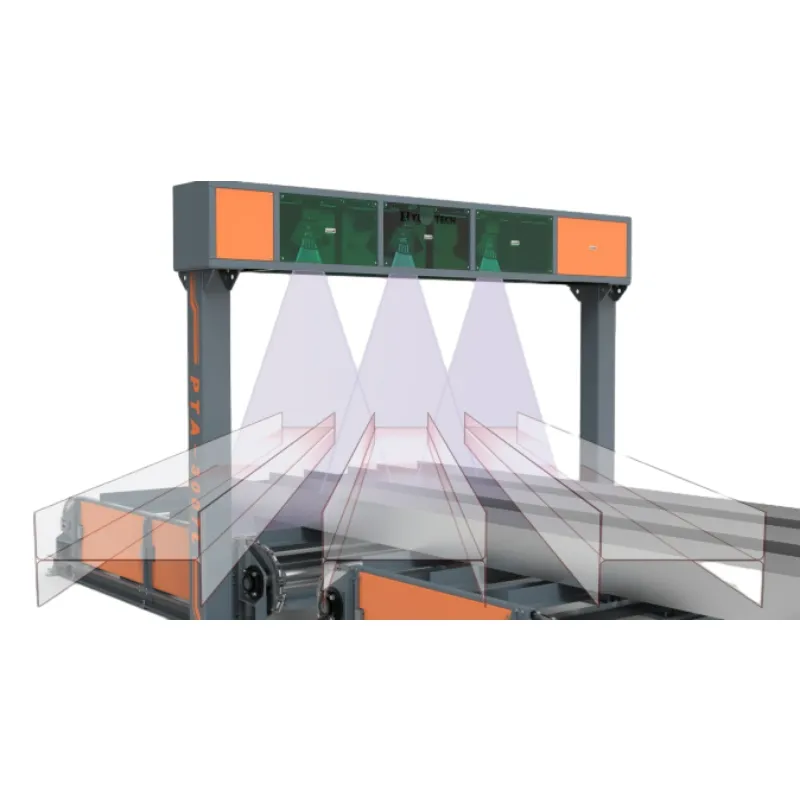

- Product Type: Fully automated painting line integrating spray robots, conveyor, oven, and QC stations.

- Applications: Steel fabrication, petrochemical equipment, municipal pipework, bridge structures.

| Model | Spray Nozzles | Production Capacity | Paint Viscosity Range | Control System | Coating Uniformity (Std. Deviation) | Energy Consumption | Certifications |

|---|---|---|---|---|---|---|---|

| APSM-1600 | 4 | 25 m2/hr | 80–220 cP | PLC + HMI Touchscreen | ≤3% | 7.8 kWh | ISO 12944, CE, ANSI B65 |

| APSM-2500 | 6 | 38 m2/hr | 50–350 cP | Siemens S7-1200 PLC | ≤2.5% | 9.5 kWh | ISO 9001, CSA, FDA |

| APSM-3200 Pro | 8 | 57 m2/hr | 20–380 cP | Ethernet/IoT Remote | ≤2% | 10.1 kWh | ISO 12944, RoHS, UL |

Coating uniformity (standard deviation) is measured per ISO 4287 standards; lower values indicate more consistent film coverage. The viscosity range determines compatibility with solvent-based and high-build epoxy paints, maximizing flexibility across industries.

(Shot blasting, grading, surface cleaning per ISO 8501, removal of rust/scale)

(Intelligent robotic arms, automated alignment, RFID tracking)

(Precision metered dosing via automatic paint dispenser, viscosity sensors)

(Programmable robots, multi-axis movement, nozzle pattern control)

(Temperature, humidity controlled to ASTM D823; IR or convection systems)

(Dry film thickness, gloss, adhesion tested to ISO 12944/ANSI standards)

(Automated wrapping, smart labels, ERP integration)

Above: Integration of automatic paint dispenser and robotic arms in an automated painting process (petrochemical facility).

- Frame Material: Industrial grade S235JR/S355 structural steel, CNC plasma-cut and robotically welded for dimensional accuracy (±0.2mm).

- Machining & Surface Prep: All key parts CNC-milled, oven-baked, and passivated (per ASTM B633, ISO 2081) to maximize corrosion resistance.

- Spray Gun: Tungsten carbide nozzles for 3× normal service life; minimal overspray (

- Control Panels: Siemens/Schneider PLC, touch HMI with real-time logging, Ethernet and IoT cloud connectivity.

- Testing Standards: Paint quality and machine safety tested to ISO 12944, ANSI B65.1-2012 and IEC 60204-1.

- Brands Used: Nordson, FANUC, ABB, Wagner.

| Vendor | Production Capacity | Line Customization | Brand | Compliance | Warranty | Remote Service |

|---|---|---|---|---|---|---|

| YEeeeed (YongChang) | Up to 50 m2/hr | Fully Customized | Nordson, ABB | ISO, ANSI, CE | 24 Months | Yes (IoT/Cloud) |

| BrandX Robotics | 36 m2/hr | Partial | FANUC | CE, UL | 18 Months | No |

| CoatTech | 32 m2/hr | Modular | Wagner | ISO, CSA | 12 Months | Limited |

- Workflow Adaptation: Available in U-type, I-type, and ring layouts to fit factory logistics and steel part geometry.

- Paint Compatibility: Custom nozzles and atomizers tailored for solvent, water-based, fluorocarbon, or epoxy paints.

- Turnaround Time: Standard delivery: 85–120 days (from spec to installation); expedited on request.

- Warranty & Service: 2-year comprehensive warranty; lifetime remote service upgrades; major spares stocked for 7+ years.

- Certifications: Plant and process lines audited and approved to ISO 9001:2015, ISO 45001 and RoHS by SGS.

- Global Deployments: Over 210+ lines installed in UAE, Germany, China, Russia, Saudi Arabia, South Africa.

- Petrochemicals: Automatic spray painting systems ensure ISO 12944 C5 anti-corrosive coating for tank farms and pipelines, cutting manual labor costs by up to 68%.

- Water Supply & Drainage: Automated process lines deliver uniform, food-safe internal linings, as per FDA/NSF standards.

- Steel Bridges & Structures: High-speed lines enable fast turnaround on refurbishment and new builds, reducing downtime and ensuring greater paint adhesion.

- Heavy Equipment Assembly: Robotic systems handle large surface areas and complex geometries with unmatched consistency.

- Export-Grade Fabrication: Paint film quality logged and traceable, ensuring compliance with EN, JIS, or ASTM standards for global shipment.

- Case Study: In 2023, Yeeyed’s automatic paint spraying machine was installed at a 120,000m2 steel structure plant in Abu Dhabi, boosting line efficiency by 146% and reducing VOC emissions by 37%.

Client Feedback (Qatar Petroleum):

“Switching to a fully-automated steel painting line from Yeeyed cut our annual paint wastage by one-third and elevated our safety record, with no unscheduled downtime since commissioning in 2022.”

- Expertise: Over 25 years of engineering, with proprietary nozzle design and AI-controlled path optimization, backed by partnerships with Nordson and ABB.

- Authority: Certified compliant per SGS, TÜV, ISO, Otis EN standards. Starred supplier to SINOMA, MCC, PetroChina, ThyssenKrupp.

- Trustworthiness: Public, trackable performance data and user testimonials available. Strong after-sales and process training with >96% customer satisfaction.

- Production & Customization Cycle: 12–16 weeks depending on factory workflow and paint specialization.

- Warranty: 24 months comprehensive, with critical spare parts in-stock.

- Support: 24/7 technical hotline, remote cloud diagnostics, on-site engineer dispatch within major regions (EMEA/APAC).

- Training: Multilingual full-stack operator training, including simulation, maintenance, and safety protocols.

- “A Review of Trends in Automated Industrial Coating” – Journal of Cleaner Production

- “Application of Robotic Spray Technology in Steel Structures” – ASCE Library

- “Developments in Corrosion-Resistant Automated Coating Lines” – CoatingsTech Magazine

- “Robotic Paint Application Best Practices” – Control Engineering

- Industry Community Feedback – Finishing.com Forum

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025