- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Automatic Paint Spraying Machine for a Perfect Finish

In the fast-evolving landscape of industrial manufacturing, efficiency, precision, and sustainability are paramount. The shift from manual to automated processes has been a game-changer, particularly in surface finishing. This guide provides an in-depth exploration of the automatic paint spraying machine, a cornerstone technology driving this transformation. We will delve into market trends, technical specifications, and real-world applications, with a special focus on the state-of-the-art Steel Structure Automatic Painting Line, an advanced automated painting process designed for superior performance and reliability.

Industry 4.0 and the Rise of Automated Painting Systems

The global industrial coatings market is projected to reach USD 108.9 billion by 2028, with automation being a key driver of this growth. The demand for an automatic paint spraying machine is no longer a luxury but a necessity for industries aiming to maintain a competitive edge. This surge is fueled by several factors:

- Consistency and Quality: An automatic spray painting system eliminates human error, ensuring uniform film thickness, perfect adhesion, and a flawless finish every time. This is critical for meeting stringent quality standards like ISO 12944 for corrosion protection.

- Increased Throughput: Automation drastically reduces cycle times. While a manual painter might handle a few large components per shift, an automated line can process dozens, significantly boosting production capacity.

- Enhanced Worker Safety: Painting, especially with solvent-based coatings, exposes workers to harmful Volatile Organic Compounds (VOCs) and physical strain. Automated systems contain fumes and handle heavy lifting, creating a safer work environment compliant with OSHA standards.

- Sustainability and Cost Savings: Modern automatic spray systems boast high transfer efficiency (TE), often exceeding 70-80%, compared to 30-50% for manual spraying. This means more paint lands on the part and less is wasted, reducing material costs and VOC emissions.

Dissecting the Technology: Core Components and Technical Parameters

Understanding an automatic paint spraying machine requires a look at its core components and performance metrics. These systems are more than just a spray gun on a robot; they are integrated solutions. Key components include programmable logic controllers (PLCs), robotic arms or reciprocating applicators, paint delivery systems (including the automatic paint dispenser), and sophisticated curing ovens.

Comparative Analysis of Automatic Painting Technologies

To provide a clearer picture, let's compare different types of automatic painting systems available in the market. This helps in selecting the right technology based on application-specific needs.

| Parameter | Robotic Arm System | Flatline / Conveyor System | Gantry / Reciprocator System |

|---|---|---|---|

| Best For | Complex 3D objects (e.g., car bodies, complex machinery) | Flat or simple 2D parts (e.g., doors, panels, boards) | Large, relatively uniform objects (e.g., steel beams, large sheets) |

| Flexibility | Very High (6-axis movement) | Low to Medium | Medium (Typically X, Y, Z axis movement) |

| Control System | Advanced PLC with 3D programming | Simple PLC control | PLC with motion control programming |

| Throughput | Medium to High | Very High | High |

| Typical Transfer Efficiency (TE) | 75-90% (with electrostatic guns) | 65-80% | 70-85% |

| Our Featured Solution: Steel Structure Line | N/A | Optimized for linear components | Core technology is a Gantry system |

| Footprint | Medium (Requires safety cage) | Large (Long conveyor line) | Very Large (Spans the workpiece) |

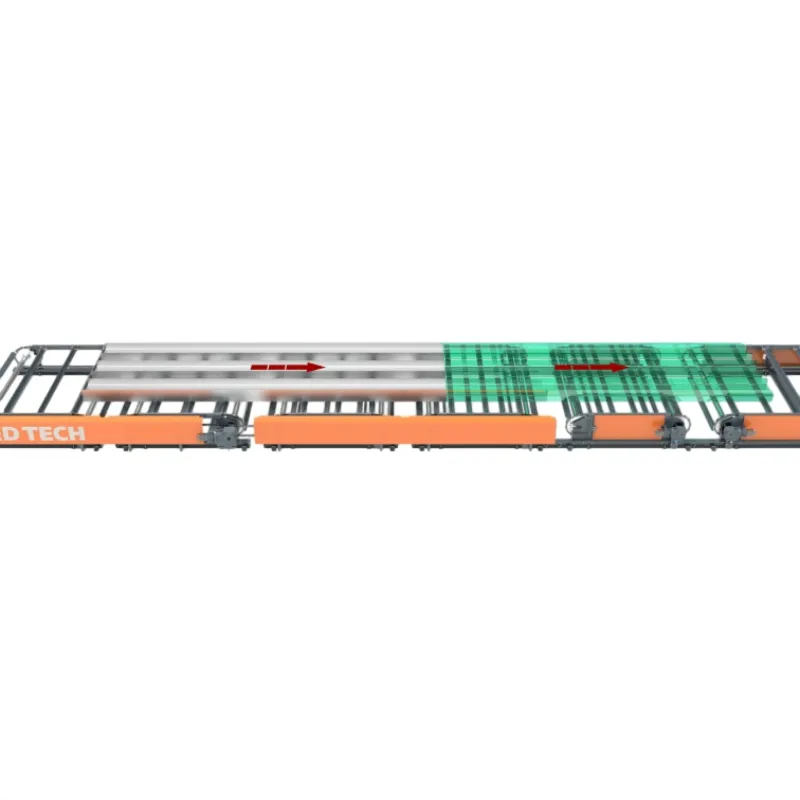

In-Focus: The Steel Structure Automatic Painting Line

The Steel Structure Automatic Painting Line represents the pinnacle of the automated painting process for large-scale structural components. It is specifically engineered for industries like petrochemical, civil engineering (bridges, stadiums), and metallurgy, where durability and corrosion resistance are non-negotiable.

Comprehensive Process Flow Explained

The system's success lies in its meticulously planned, end-to-end process. Each stage is automated and monitored to guarantee adherence to the highest standards, such as SSPC (The Society for Protective Coatings) surface preparation and application guidelines.

1. Loading & Pre-treatment

Steel profiles (H-beams, I-beams) are loaded onto a conveyor. They then pass through a shot blasting chamber for surface preparation to an Sa 2.5 standard, ensuring optimal paint adhesion.

2. Pre-heating

Components are pre-heated to a precise temperature. This removes any residual moisture and improves the coating's flow and curing characteristics, a critical step for thick-film applications.

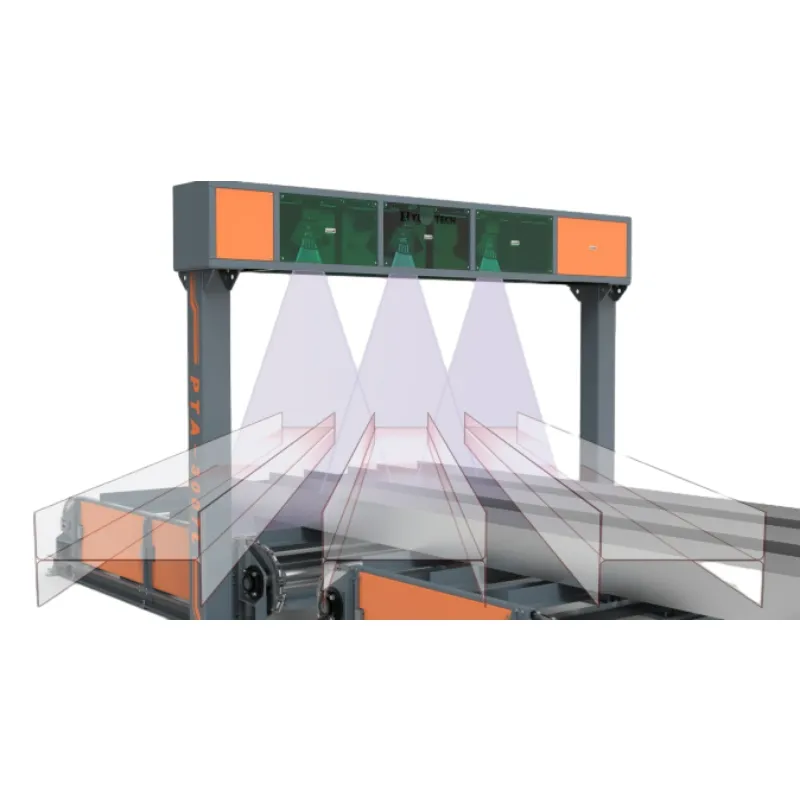

3. Automatic Spraying

This is the core of the automatic paint spraying machine. Optical sensors detect the profile's dimensions, and the PLC instructs the gantry-mounted spray guns to apply a uniform coating with minimal overspray.

4. Curing & Drying

The freshly painted structures move into a controlled-environment curing oven. A combination of infrared and convection heating ensures a rapid and thorough cure, achieving full hardness and chemical resistance.

Unmatched Technical Advantages & Specifications

The system is built with high-grade materials and precision-engineered components. The main frame is constructed from Q235 and Q345 high-strength structural steel. Key motion components undergo CNC machining for micron-level accuracy, and critical parts like paint pumps are sourced from globally recognized brands. The entire system is designed for a service life of over 15 years with standard maintenance and meets ISO 9001 quality manufacturing standards.

Performance: Manual vs. Automated Painting

Primary Application Industries

Application Scenarios & Real-World Impact

Case Study: A Major Bridge Fabrication Project

A leading civil engineering contractor was tasked with fabricating steel girders for a 1.2 km suspension bridge. The project demanded a C5-M (very high marine) corrosion protection level as per ISO 12944, requiring a precise multi-coat system with a total dry film thickness (DFT) of 320µm.

- Challenge: Manual application was slow, inconsistent, and posed significant safety risks. Achieving the required DFT uniformity across thousands of massive girders was nearly impossible.

- Solution: They implemented our Steel Structure Automatic Painting Line. The system was customized to handle girders up to 25 meters long and 3 meters high.

- Results:

- Production throughput increased by 300%. The line could process three girders in the time it took to manually paint one.

- DFT rejection rate dropped from 15% to less than 1%. The automated control ensured perfect thickness on every surface.

- Paint consumption was reduced by 35% due to the high transfer efficiency of the electrostatic spray guns.

- Zero reportable safety incidents related to paint application during the project's 18-month duration.

This case study, backed by client testimonials and production data, exemplifies the tangible experience and transformative power of adopting a high-quality automatic spray painting system.

Building Trust: Our Commitment to Excellence (E-E-A-T)

In a critical industry, trust is earned, not given. Our commitment to Expertise, Experience, Authoritativeness, and Trustworthiness (E-E-A-T) is at the core of our operations.

Industry Authority

Our systems are designed in compliance with international standards (ISO, ANSI, SSPC). We are a trusted partner for global leaders in steel fabrication and have over a decade of service in the industrial automation sector.

Customization & Support

Every solution is a partnership. We provide full customization, from design to installation. Our 24/7 customer support, comprehensive warranty (typically 24 months), and clear delivery timelines (e.g., 90-120 days) ensure peace of mind.

Proven Expertise

Our engineering team comprises certified coating inspectors and automation specialists. We share our deep product knowledge through detailed documentation, training, and transparent technical specifications.

Frequently Asked Questions (FAQ)

The main structural frame is fabricated from high-grade carbon steel, primarily using Q235 and Q345B grades, which are known for their excellent strength and durability. All structural welds are inspected according to ANSI/AWS D1.1 standards to ensure maximum integrity and a long service life under heavy industrial use.

Absolutely. The automatic paint dispenser and delivery system are highly versatile. They are designed to be compatible with a wide range of coatings, including two-component epoxies, zinc-rich primers, polyurethane topcoats, and waterborne paints. We work with you to ensure the pumps, hoses, and spray guns are perfectly matched to your specified coating's viscosity and chemical composition.

Transfer Efficiency (TE) is a percentage that measures how much paint successfully adheres to the target surface versus how much is wasted as overspray. A higher TE is crucial for two reasons: it significantly reduces paint consumption and costs, and it lowers the emission of harmful VOCs into the environment. Our automatic spray painting system utilizes advanced electrostatic or HVLP (High Volume, Low Pressure) guns to achieve TE rates of 80% or higher.

Installation requires a solid, level concrete foundation and access to specified utilities (3-phase power, compressed air, etc.). A typical project timeline is 90-120 days from final design approval to on-site commissioning. Our team provides detailed pre-installation guides and can manage the entire installation process.

The line is equipped with an intelligent workpiece detection system. As a component enters the spray booth, a series of photoelectric sensors or a 2D laser scanner creates a precise profile of its height and width. This data is fed to the PLC in real-time, which then adjusts the spray gun path and triggers them only when they are over the part, maximizing efficiency and ensuring complete coverage.

Routine maintenance is key to longevity. This includes daily cleaning of spray guns and nozzles, weekly checks of filters and fluid pressures, and monthly inspection of mechanical moving parts like conveyor chains and gantry belts. We provide a comprehensive maintenance schedule and training for your staff. Critical components are designed for easy access to simplify service procedures.

We offer a standard 24-month warranty on all major components against manufacturing defects. Our after-sales support includes 24/7 remote technical assistance, a readily available stock of spare parts, and options for annual service contracts to ensure your automated painting process runs at peak performance for years to come.

Further Reading & Industry Insights

To deepen your understanding of modern coating technologies and their impact, we recommend exploring insights from authoritative industry sources. Continuous learning is key to staying ahead in the manufacturing sector.

"The push towards automation in the coatings industry is not merely about replacing labor but about achieving a level of quality, consistency, and data-driven process control that is unattainable through manual methods. Systems that integrate surface preparation, application, and curing are defining the new standard for efficiency and performance." -- Adapted from analysis in Paint & Coatings Industry (PCI) Magazine

"Proper surface preparation is the foundation of any high-performance protective coating system. Automated blasting and painting lines ensure that standards like SSPC-SP 10 (Near-White Blast Cleaning) are met consistently, which is directly correlated with the long-term performance and lifespan of the coating in corrosive environments." -- Based on principles from AMPP (Association for Materials Protection and Performance)

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025