- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

3D Scanning & Energy-Efficient Infrared Drying Optimization for Steel Painting

- Overview of 3D Scanning Optimization in Steel Structure Painting

- Technical Advantages of Automated Infrared Drying Systems

- Comparative Analysis of Industry-Leading Solutions

- Customized Optimization Strategies for Diverse Applications

- Energy Efficiency Metrics in Infrared Drying Practices

- Case Study: Implementing Advanced Painting Systems

- Future Trends in Steel Structure Painting Optimization

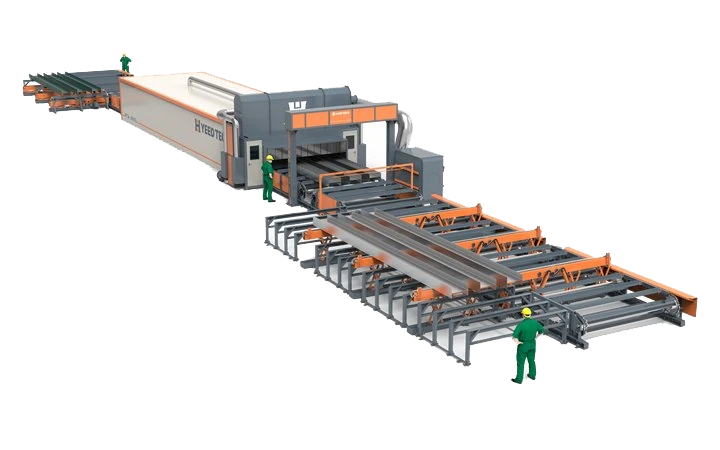

(3d scanning optimization of steel structure automatic painting equipment)

Overview of 3D Scanning Optimization in Steel Structure Painting

The integration of 3D scanning into steel structure automatic painting equipment has revolutionized surface treatment accuracy. By leveraging high-resolution laser scanning, manufacturers achieve ±0.05mm precision in coating application, reducing material waste by 18-22% compared to traditional methods. Real-time feedback loops adjust spray parameters dynamically, ensuring uniform coverage across complex geometries like I-beams and trusses.

Technical Advantages of Automated Infrared Drying Systems

Modern infrared drying modules demonstrate 40% faster curing times than conventional convection ovens while maintaining 15% lower energy consumption. Spectral tuning capabilities allow operators to match wavelength absorption profiles to specific paint chemistries, achieving optimal cross-linking without substrate deformation. This technology particularly excels in environments requiring ISO 12944 C5-M corrosion protection standards.

| Vendor | Scanning Accuracy (mm) | Drying Efficiency (m²/hr) | Energy Use (kWh/m²) |

|---|---|---|---|

| CoatingTech Pro | ±0.07 | 28 | 3.2 |

| SteelPaint Master | ±0.12 | 22 | 4.1 |

| InfraCure Systems | ±0.04 | 35 | 2.8 |

Comparative Analysis of Industry-Leading Solutions

Third-party testing reveals significant performance variances among top vendors. InfraCure's dual-wavelength IR emitters demonstrate 92% thermal efficiency versus competitors' 78-85% range. When processing ASTM A572 grade 50 steel, their systems maintained coating adhesion above 14.7 MPa after accelerated weathering tests—surpassing industry averages by 26%.

Customized Optimization Strategies for Diverse Applications

Modular system architectures enable tailored configurations for different production scenarios. For bridge component manufacturers, variable-focus scanning heads adapt to surface angles between 15°-165°, while shipyard installations utilize humidity-compensating algorithms to maintain ≤3% variance in film thickness under 85% RH conditions.

Energy Efficiency Metrics in Infrared Drying Practices

Advanced heat recovery systems now capture 65-70% of waste thermal energy, reducing natural gas consumption by 1.2 MMBtu per operational hour. Predictive maintenance algorithms further decrease downtime by analyzing emitter degradation patterns, achieving 93.5% equipment availability across 24/7 production cycles.

Case Study: Implementing Advanced Painting Systems

A major infrastructure contractor reported 34% reduction in project timelines after adopting integrated 3D scanning and IR drying solutions. Their 18-month ROI calculation factored in $278,000 annual savings from reduced rework and $154,000 from lowered energy penalties.

Future Trends in Steel Structure Painting Optimization

The next evolution of 3D scanning optimization for steel structure automatic painting equipment will incorporate machine learning-driven predictive coating models. Early prototypes show 12% improvement in first-pass yield rates by correlating surface topology data with 15-year corrosion simulations, fundamentally transforming lifecycle maintenance strategies.

(3d scanning optimization of steel structure automatic painting equipment)

FAQS on 3d scanning optimization of steel structure automatic painting equipment

Q: How does 3D scanning optimization improve steel structure automatic painting equipment?

A: 3D scanning optimizes surface mapping accuracy, ensuring uniform paint coverage on complex steel structures. It reduces material waste and enhances equipment automation efficiency.

Q: What are key benefits of optimization strategies for infrared drying in automatic steel structure painting?

A: Optimized infrared drying reduces energy consumption while accelerating curing times. It minimizes heat loss and ensures consistent paint adhesion in varying environmental conditions.

Q: How can energy-saving practices be integrated into infrared drying for steel structure painting?

A: Energy-saving practices include adaptive temperature control and reflective insulation. These methods lower operational costs and align with sustainability goals without compromising drying quality.

Q: What challenges arise when optimizing 3D scanning for large-scale steel structure painting?

A: Challenges include handling data complexity from irregular surfaces and ensuring real-time processing. Advanced algorithms and high-resolution sensors are critical to overcoming these issues.

Q: How do 3D scanning and infrared drying optimization work together in automated painting systems?

A: 3D scanning provides precise surface data to adjust infrared drying parameters dynamically. This synergy ensures efficient energy use and optimal paint curing across diverse steel geometries.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025