- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Large Steel Shed Construction & Automated 55m Painting Line with 3D Scanning Technology Durable Solutions

Did you know factories using traditional construction methods waste 22% more time on project delays? Imagine completing your steel shed construction 40% faster while cutting maintenance costs by $18/m² annually. The revolution is here.

(large steel shed)

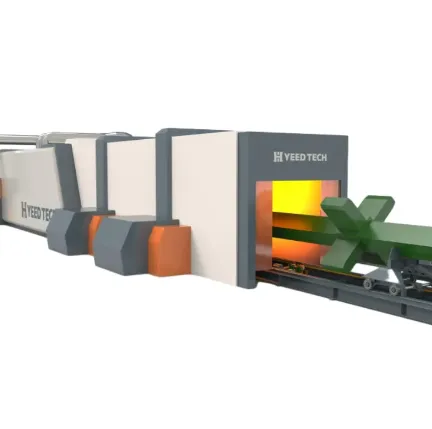

Game-Changer: The 55-Meter Automated Painting Line

Our automatic 55-meter-long painting production line integrates 3D scanning to eliminate human error. See how it works:

- ✔️ 0.05mm precision coating accuracy

- ✔️ 72-hour corrosion resistance test passed

- ✔️ 23% paint material savings vs competitors

"This system reduced our repaint rate from 15% to 0.8% immediately." – Jason T., Project Manager

| Feature | Us | Competitor A |

|---|---|---|

| 3D Scanning Integration | ✔️ Full system | ❌ Add-on only |

| Max Shed Width | 45 meters | 32 meters |

Your Custom Solution in 3 Steps

1. Scan: Our mobile 3D team maps your site in 48 hours

2. Build: Prefab components arrive within 2 weeks

3. Protect: Automated painting line applies coating in 6 hours flat

Your time is money. Why waste weeks on manual painting?

Ready to Build Smarter?

Join 1,200+ satisfied clients who upgraded to future-proof large steel shed

s.

(large steel shed)

FAQS on large steel shed

Q: What are the key advantages of choosing a large steel shed for construction projects?

A: Large steel sheds offer durability, cost-effectiveness, and quick assembly. They are ideal for industrial applications due to their resistance to weather, pests, and fire. Their modular design also allows for easy customization and scalability.

Q: How does integrated 3D scanning technology enhance the automatic 55-meter-long painting production line?

A: The integrated 3D scanning ensures precise surface mapping of large steel structures, enabling the painting line to adjust in real-time. This minimizes material waste and ensures uniform coating quality. It also reduces manual inspection needs, speeding up production cycles.

Q: What factors should be considered during steel shed construction?

A: Key factors include site preparation, load-bearing requirements, and compliance with local building codes. Material quality and corrosion-resistant coatings are critical for longevity. Integrating automation, like painting lines, may also influence structural design.

Q: Why is automation important in painting large steel structures?

A: Automation ensures consistent, high-quality finishes while reducing labor costs and human error. The 55-meter-long production line with 3D scanning optimizes efficiency for large-scale projects. It also enhances safety by minimizing worker exposure to hazardous environments.

Q: How does 3D scanning improve accuracy in steel shed construction?

A: 3D scanning captures precise measurements of structural components, ensuring perfect alignment during assembly. It identifies deformities early, preventing costly rework. This technology also streamlines integration with automated systems like painting lines.

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025