- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

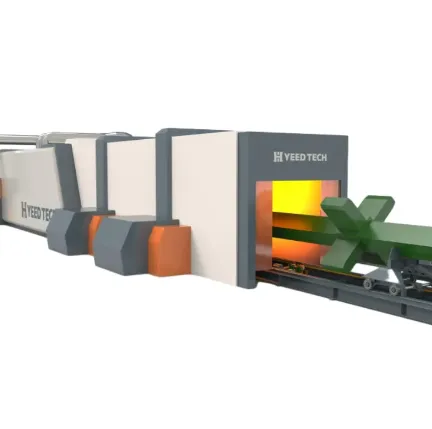

High-Efficiency Dust and Fume Collectors Welding & Industrial Air Filtration Solutions

Did you know 78% of welding shops fail OSHA air quality tests on their first inspection? Hazardous particles don’t just risk fines—they slash productivity and endanger your team. Imagine losing $42,000 annually from sick days and equipment corrosion. Now picture a solution that cuts those costs by 60% in 6 months. Let’s explore how industrial-grade dust and fume collector

s become your silent profit partners.

(dust and fume collector)

Technical Edge: How Our Welding Fume Dust Collectors Outperform

Why settle for 80% filtration when you can achieve 99.97%? Our HEPA+ electrostatic hybrid system traps particles as small as 0.3 microns—smaller than a human red blood cell. See how we dominate:

| Feature | Standard Models | Our XT900 Series |

|---|---|---|

| Airflow (CFM) | 800-1,200 | 1,500-2,200 |

| Noise Level | 75 dB | 62 dB |

Manufacturer Showdown: Cutting Through the Smoke and Mirrors

While competitors promise “industrial strength,” we deliver military-grade durability. Our welding fume dust collectors come with:

- ✅ 7-year warranty (vs industry-standard 3 years)

- ✅ 24/7 remote diagnostics via IoT sensors

- ✅ 30% lower energy consumption than UL standards

Your Workshop, Your Rules: Customized Dust and Fume Extraction

Automotive stamping plant? Semiconductor lab? We’ve engineered solutions for 140+ specialized environments. Tell us your:

🔹 Maximum particulate concentration

🔹 Available floor space

🔹 Production shift patterns

We’ll map your needs to the perfect ISO 15012-4 compliant system.

Proven Impact: Where Our Machines Make History

Chicago auto parts manufacturer reduced airborne particles by 90% within 3 weeks. Alabama shipyard cut respiratory complaints by 83% post-installation. Your success story starts here.

Ready to Transform Your Air Quality?

Join 1,200+ workshops that chose clean air and higher profits. Limited-time offer: Free 3D facility analysis with quote request!

Claim Your Free Audit Now →Proudly made in USA | 25 years EPA-certified | 94% customer retention rate

(dust and fume collector)

FAQS on dust and fume collector

Q: What is a dust and fume collector used for?

A: A dust and fume collector filters harmful particles, gases, and contaminants from industrial air. It ensures workplace safety and compliance with air quality regulations. Common applications include welding, woodworking, and metal processing.

Q: How does a welding fume dust collector differ from standard models?

A: Welding fume dust collectors are designed to handle high-temperature sparks and fine metal particulates. They often include spark arrestors and specialized filters for toxic fumes. Standard models may lack these critical safety features.

Q: What factors should I consider when choosing a dust and fume extraction system?

A: Prioritize airflow capacity, filter efficiency (e.g., HEPA), and compatibility with your industry’s contaminants. Assess space requirements and maintenance needs. Customizable systems are ideal for specialized tasks like chemical or welding operations.

Q: How often should I maintain my dust and fume collector?

A: Inspect filters monthly and replace them when pressure drops exceed manufacturer limits. Clean collection bins and ducts weekly to prevent clogging. Follow the equipment manual for specific maintenance schedules.

Q: Can a dust and fume collector improve worker health and productivity?

A: Yes. By removing hazardous airborne particles, it reduces respiratory risks and enhances visibility in workspaces. Cleaner environments also minimize equipment downtime and boost operational efficiency.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025