- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Januari . 19, 2025 02:34

Back To List

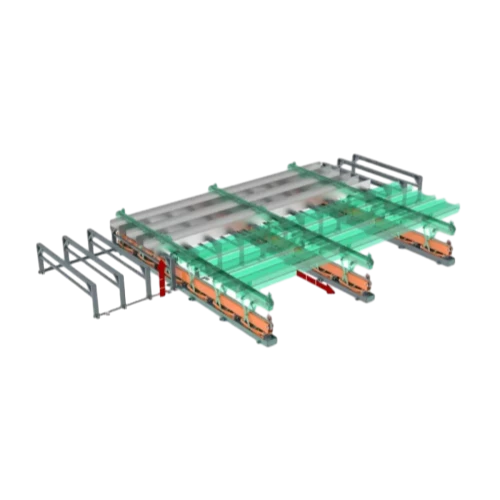

automatic spray painting system

Creating an automated spray painting machine project is a fascinating venture that stands at the intersection of technology and artistry, offering efficiency and precision in commercial and industrial applications. This innovation not only enhances productivity but also ensures a high quality of finish, which manual methods may not consistently achieve. Here's an in-depth exploration of this technology, emphasizing its applications, benefits, and key components to consider.

Health and safety are also paramount when deploying automated spray painting machines. These systems significantly reduce exposure to hazardous fumes and particulate matter, creating a safer working environment for operators. Moreover, they come equipped with enclosed spray booths and ventilation systems designed to effectively capture and filter out volatile organic compounds (VOCs), thereby ensuring compliance with environmental regulations. From a maintenance perspective, automated spray painting machines are designed for durability and ease of upkeep. Regular maintenance routines, such as nozzle cleaning, filter replacements, and software updates, are essential to maintain peak performance and prolong the machine's lifespan. Additionally, manufacturers often offer comprehensive support services, including training and technical assistance, to help businesses maximize their investment's productivity and efficiency. The adoption of automated spray painting technology also aligns with the growing trend towards Industry 4.0, where automation and data exchange in manufacturing are key drivers of innovation. These machines can be integrated into a smart factory setup, utilizing IoT devices to track performance, diagnose issues, and predict maintenance needs, further improving efficiency and minimizing downtime. In conclusion, automated spray painting machines represent a significant advancement in industrial painting, offering precision, efficiency, and safety. For businesses aiming to enhance their production capabilities and meet modern demands, investing in such technology is a strategic decision. As the industry evolves, continuous advancements in robotics and software will only amplify these machines' potential, solidifying their status as essential tools in the realm of automated manufacturing processes.

Health and safety are also paramount when deploying automated spray painting machines. These systems significantly reduce exposure to hazardous fumes and particulate matter, creating a safer working environment for operators. Moreover, they come equipped with enclosed spray booths and ventilation systems designed to effectively capture and filter out volatile organic compounds (VOCs), thereby ensuring compliance with environmental regulations. From a maintenance perspective, automated spray painting machines are designed for durability and ease of upkeep. Regular maintenance routines, such as nozzle cleaning, filter replacements, and software updates, are essential to maintain peak performance and prolong the machine's lifespan. Additionally, manufacturers often offer comprehensive support services, including training and technical assistance, to help businesses maximize their investment's productivity and efficiency. The adoption of automated spray painting technology also aligns with the growing trend towards Industry 4.0, where automation and data exchange in manufacturing are key drivers of innovation. These machines can be integrated into a smart factory setup, utilizing IoT devices to track performance, diagnose issues, and predict maintenance needs, further improving efficiency and minimizing downtime. In conclusion, automated spray painting machines represent a significant advancement in industrial painting, offering precision, efficiency, and safety. For businesses aiming to enhance their production capabilities and meet modern demands, investing in such technology is a strategic decision. As the industry evolves, continuous advancements in robotics and software will only amplify these machines' potential, solidifying their status as essential tools in the realm of automated manufacturing processes.

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025