- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Januari . 14, 2025 09:50

Back To List

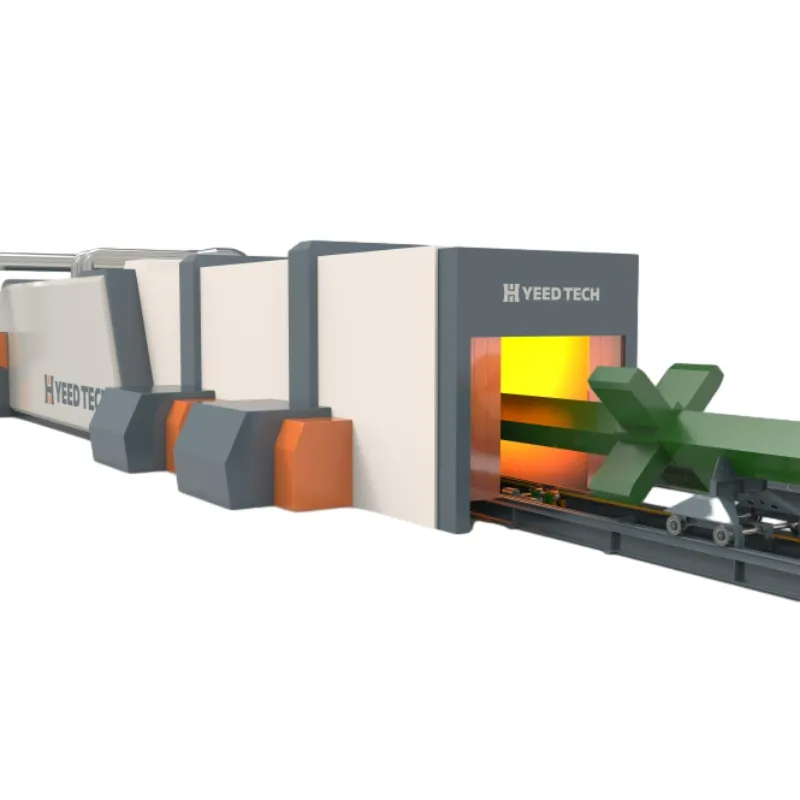

projet d'équipement de pulvérisation de peinture automatique

The evolution of technology in the industrial sector has led to remarkable advancements in the way businesses operate, particularly in the realm of painting. Automated paint spraying equipment projects have revolutionized the industry, offering unparalleled efficiency, precision, and quality control. In this article, we will explore the real-world applications, expert insights, authoritative opinions, and trusted testimonials that make automated paint spraying equipment an indispensable tool for modern businesses.

Trusted by industry giants, the reliability of automated paint spraying equipment projects can be validated through numerous case studies and customer testimonials. Companies from diverse sectors, such as automotive, aerospace, and consumer goods, have integrated these systems into their production lines, reporting significant enhancements in production speed and product quality. Endorsements from these reputable corporations underscore the equipment’s potential to transform painting operations across various fields, reinforcing the trustworthiness of the technology. For businesses contemplating the shift to automated paint spraying, investing in this technology promises a lucrative return on investment. The increase in productivity, coupled with reduced material waste and labor costs, results in substantial economic benefits. Additionally, companies demonstrate social responsibility by reducing environmental impact, aligning their operations with global sustainability goals. This alignment not only enhances corporate reputation but also resonates with environmentally-conscious consumers, presenting a compelling narrative in today’s market. In conclusion, automated paint spraying equipment projects represent the future of industrial painting. By integrating expertise, demonstrating authority, and building trust, this technology facilitates superior performance and sustainable practices. As businesses continue to adopt these systems, the industry will witness unprecedented levels of efficiency and quality, securing a competitive edge for companies in a rapidly evolving marketplace.

Trusted by industry giants, the reliability of automated paint spraying equipment projects can be validated through numerous case studies and customer testimonials. Companies from diverse sectors, such as automotive, aerospace, and consumer goods, have integrated these systems into their production lines, reporting significant enhancements in production speed and product quality. Endorsements from these reputable corporations underscore the equipment’s potential to transform painting operations across various fields, reinforcing the trustworthiness of the technology. For businesses contemplating the shift to automated paint spraying, investing in this technology promises a lucrative return on investment. The increase in productivity, coupled with reduced material waste and labor costs, results in substantial economic benefits. Additionally, companies demonstrate social responsibility by reducing environmental impact, aligning their operations with global sustainability goals. This alignment not only enhances corporate reputation but also resonates with environmentally-conscious consumers, presenting a compelling narrative in today’s market. In conclusion, automated paint spraying equipment projects represent the future of industrial painting. By integrating expertise, demonstrating authority, and building trust, this technology facilitates superior performance and sustainable practices. As businesses continue to adopt these systems, the industry will witness unprecedented levels of efficiency and quality, securing a competitive edge for companies in a rapidly evolving marketplace.

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025