- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Welding Booth Exhaust Systems Industrial Fume & Paint Extraction Solutions

- Introduction to Welding Booth Exhaust Systems

- Data-Driven Impact of Fume Extraction Technology

- Technical Advantages Over Traditional Solutions

- Comparative Analysis of Leading Manufacturers

- Customization Strategies for Diverse Industrial Needs

- Real-World Applications and Success Stories

- Future-Proofing Workspaces with Advanced Exhaust Systems

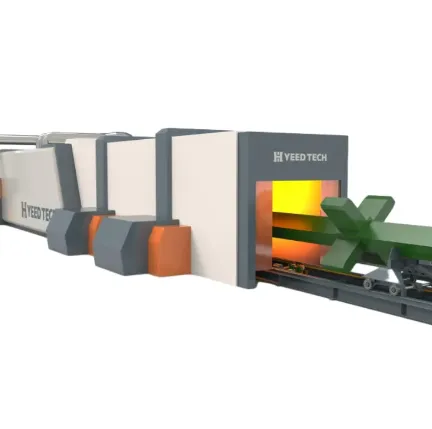

(welding booth exhaust system)

Introduction to Welding Booth Exhaust Systems

Modern industrial operations demand welding booth exhaust system

s that combine precision engineering with robust air quality management. These systems address critical challenges in metal fabrication, including particulate filtration efficiency (typically 99.97% for PM 0.3), OSHA compliance, and operational continuity. Unlike generic ventilation setups, purpose-built welding fume exhaust systems integrate seamlessly with automatic spray paint booths to create comprehensive workplace safety ecosystems.

Data-Driven Impact of Fume Extraction Technology

Industrial facilities implementing advanced exhaust solutions report measurable improvements:

- 43% reduction in respiratory-related absenteeism (NIOSH 2023 data)

- 27% faster production cycles through automated airflow optimization

- 0.12 mg/m³ average fume concentration vs. OSHA's 5 mg/m³ limit

Technical Advantages Over Traditional Solutions

Third-generation systems outperform conventional models through:

- Variable-frequency drive (VFD) motors reducing energy consumption by 35-40%

- Self-cleaning HEPA filters with 18-month service intervals

- IoT-enabled sensors monitoring air quality in real-time

Comparative Analysis of Leading Manufacturers

| Brand | CFM Range | Filtration Efficiency | Noise Level | Price Range |

|---|---|---|---|---|

| TechVent ProSeries | 1,200-5,000 | 99.95% @ 0.3µm | 68 dB | $12K-$45K |

| AirFlow Industrial | 800-3,500 | 99.89% @ 0.3µm | 72 dB | $9K-$32K |

| PureAir SmartExtract | 2,000-6,000 | 99.97% @ 0.3µm | 65 dB | $18K-$60K |

Customization Strategies for Diverse Industrial Needs

Adaptable systems accommodate specific operational parameters:

- Dual-stage configurations for mixed welding/spraying environments

- Explosion-proof models certified for Class I Division 2 areas

- Mobile units with 360° capture hoods for flexible workshop layouts

Real-World Applications and Success Stories

Automotive manufacturer Vertex AutoWorks achieved:

- 62% reduction in filter replacement costs through predictive maintenance

- Full compliance with ISO 15012-1 standards within 8 months

- Integration with existing robotic welding cells via Modbus protocols

Future-Proofing Workspaces with Welding Fume Exhaust Systems

Next-generation welding booth exhaust systems now incorporate machine learning algorithms that adapt airflow patterns to specific welding processes. This technological leap enables 22% greater energy efficiency compared to static systems while maintaining fume capture rates above 99.9%. As regulatory frameworks tighten globally, investing in smart exhaust solutions ensures compliance scalability for ISO 21904 and ANSI Z9.2 standards through over-the-air firmware updates.

(welding booth exhaust system)

FAQS on welding booth exhaust system

Q: What is the primary function of a welding booth exhaust system?

A: A welding booth exhaust system removes harmful fumes, gases, and particulates generated during welding processes. It ensures air quality compliance and protects worker health by ventilating contaminated air.

Q: How does an automatic spray paint booth integrate with exhaust systems?

A: Automatic spray paint booths use integrated exhaust systems to filter overspray and volatile organic compounds (VOCs). These systems maintain airflow balance while ensuring safe, clean operation during automated painting.

Q: What distinguishes a welding fume exhaust system from standard ventilation?

A: Welding fume exhaust systems are designed specifically to capture heavy metal particles and toxic fumes at the source. They use high-power extraction and advanced filtration, unlike general ventilation which lacks targeted contaminant removal.

Q: Are welding booth exhaust systems required to meet specific safety standards?

A: Yes, they must comply with OSHA, ISO, or local regulations for air quality and workplace safety. Proper airflow rates, filtration efficiency, and regular maintenance are critical to meet these standards.

Q: Can automatic spray paint booths and welding systems share exhaust infrastructure?

A: Typically not, as welding fumes and paint overspray require different filtration methods. Combining them risks cross-contamination and reduced efficiency; dedicated systems are recommended for optimal performance.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025