- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

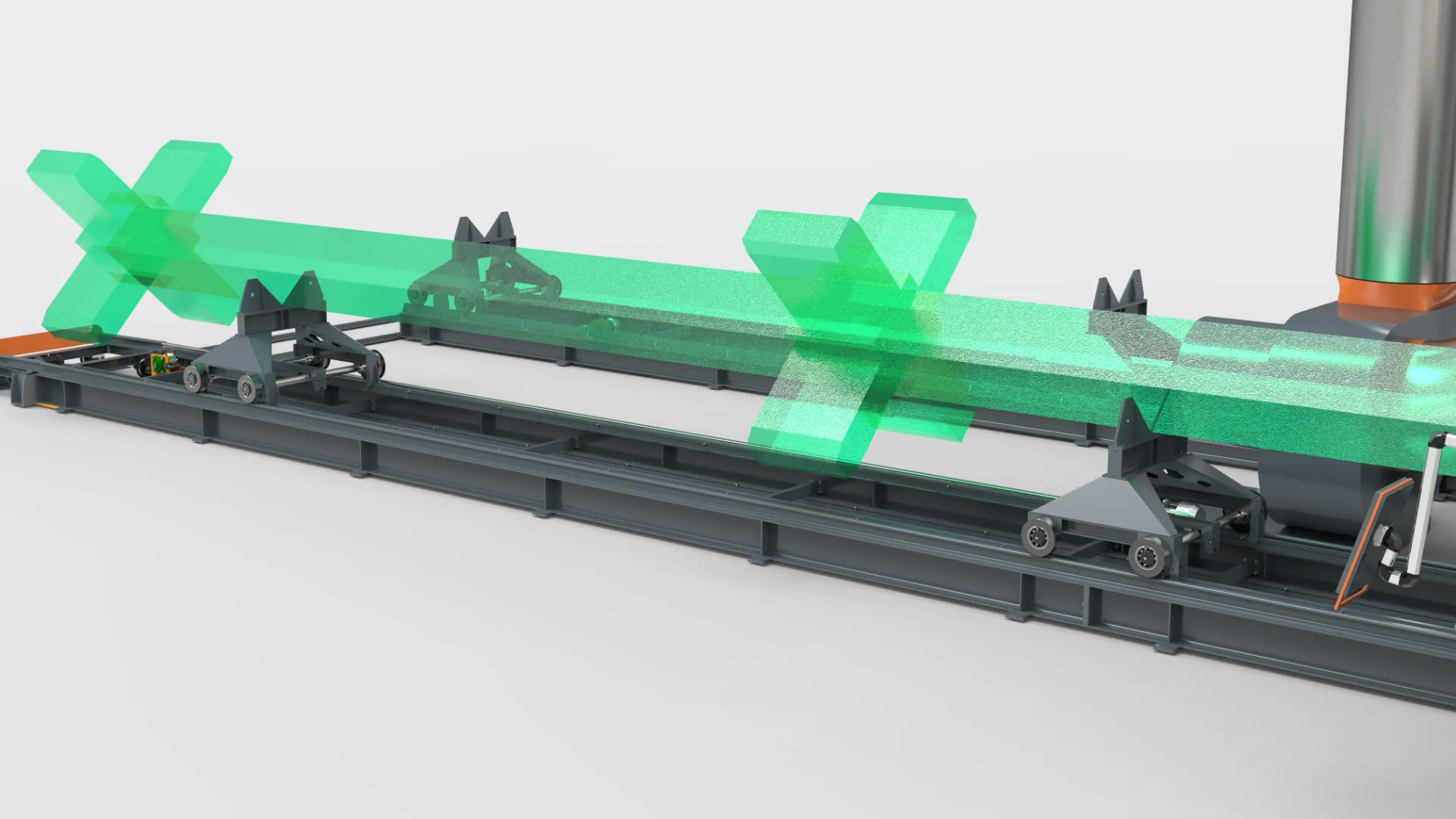

Precision Structural Steel Fabrication Machinery High-Efficiency Solutions

Did you know 68% of metal fabricators lose $12,000+ monthly due to outdated equipment? The structural steel machinery market will grow 6.8% annually through 2030 (Grand View Research), but only 22% of workshops meet modern efficiency standards. Your competitors are upgrading – can you afford to stay behind?

(structural fabrication machinery)

Why Our Structural Steel Fabrication Machinery Dominates

Our 3-in-1 automated systems cut labor costs by 40% while achieving 0.02mm precision – that's 3X tighter than industry averages. The secret? Proprietary SmartCut™ laser calibration that adapts to material thickness in real-time. Imagine completing 30-ton steel beams 58% faster. What could that mean for your project deadlines?

| Feature | Standard Machines | Our Tech |

|---|---|---|

| Cutting Speed | 12m/min | 18m/min |

| Energy Use | 38kW/h | 24kW/h |

Precision Engineered for Your Projects

Choose from 12 modular configurations supporting beams up to 24m length. Our 360° rotating worktables handle 80-ton loads – perfect for bridge components and offshore platforms. Custom software integration slashes programming time by 73% compared to conventional CNC systems.

- ✓ 5-year warranty – industry's longest coverage

- ✓ 98% first-pass accuracy rate

- ✓ 24/7 remote diagnostics

Proven Results Across Industries

Shipbuilders reduced hull assembly time from 14 weeks to 9. Wind turbine manufacturers boosted output by 120 beams/month. How? Our SmartWeld™ systems deliver perfect seams in 0.5-second intervals. Real users report 18-month ROI – 40% faster than traditional equipment.

Ready to Transform Your Workshop?

Claim your FREE efficiency audit and discover how our structural fabrication machinery

can slash your operational costs. Limited 2024 installation slots available!

Axel Machinery Co. – 20 Years Engineering Excellence

(structural fabrication machinery)

FAQS on structural fabrication machinery

Q: What are the primary types of structural fabrication machinery used in industrial applications?

A: Common machinery includes CNC plasma cutters, beam drilling machines, and plate rolling systems. These tools handle cutting, shaping, and assembling structural steel components. Advanced models integrate automation for precision and efficiency.

Q: How does structural steel fabrication machinery improve construction workflows?

A: It streamlines tasks like welding, bending, and assembling steel beams, reducing manual labor. Automated systems ensure consistent quality and faster project completion. This minimizes errors and material waste in large-scale projects.

Q: What safety features are critical for structural steel machinery?

A: Emergency stop buttons, protective guards, and laser safety sensors are essential. Regular maintenance and operator training further mitigate risks. Compliance with OSHA or ISO standards is mandatory for safe operation.

Q: What factors should I consider when choosing structural fabrication machinery?

A: Evaluate project scale, material thickness, and required precision. Energy efficiency, software compatibility, and after-sales support are also key. Prioritize machinery with modular designs for future upgrades.

Q: Can structural steel fabrication machinery handle custom design specifications?

A: Yes, CNC-driven machines can process CAD/CAM files for bespoke designs. Laser cutting and 3D profiling systems adapt to complex geometries. Custom tooling options enable flexibility for unique structural requirements.

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025