- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Advanced Structural Coatings | GPT-4 Turbo AI

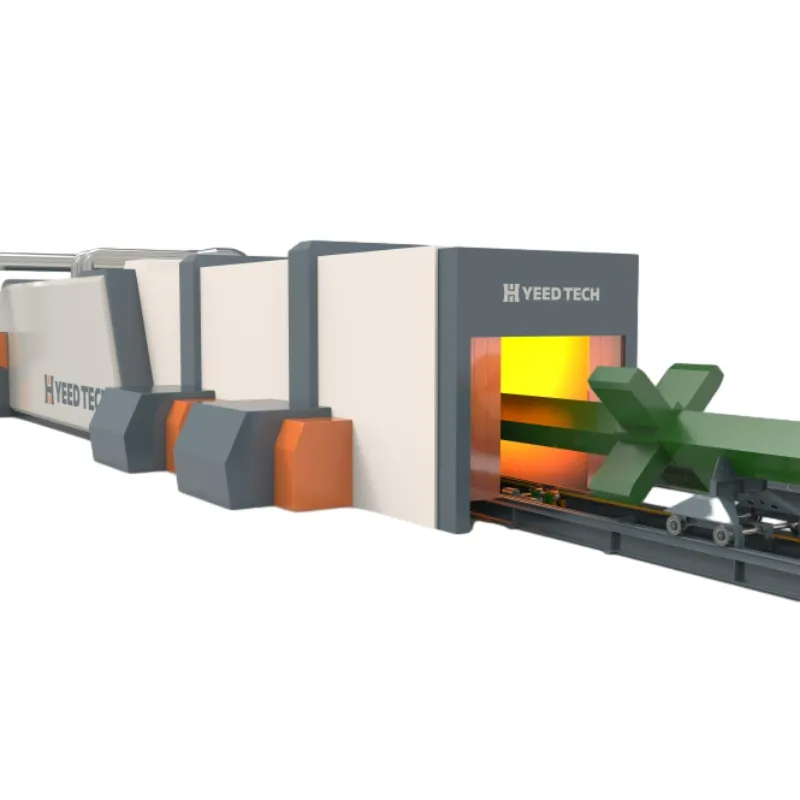

Structural coating technologies are revolutionizing the integrity and longevity of steel infrastructure worldwide. Designed to protect, enhance, and prolong the service life of structural steel in challenging environments, these advanced coatings are critical for industries such as oil & gas, petrochemicals, metallurgy, and waterworks. In this guide, we offer an expert exploration of structural coating, cutting-edge spray painting line solutions, and a detailed analysis of the structural steel painting cost in modern projects.

We'll cover the manufacturing workflows, principal technical parameters, market trends, and the unique value offered by the Heavy Steel Structure Painting Line. Real data tables, product comparison charts, usage scenarios, and application cases are included to help project owners, engineers, and procurement teams make well-informed, cost-effective decisions.

- Global Market Size: The global structural coating market was valued at over $14.8 billion in 2023, projected to grow at CAGR 5.1% (2024-2029) (MarketsandMarkets).

- Technology Upgrades: Automatic high-efficiency spray painting lines are replacing manual painting; sustainability and environmental compliance (ISO 12944, ANSI/AWS D1.1) are key technical drivers.

- Industry Adoption: Segment demand led by petrochemical plants, metallurgical structures, municipal bridges, and power stations.

- Cost Pressures: Optimization of structural steel painting cost by energy-saving, high-yield coating systems and digital process management.

| Property | Technical Value/Range | Test Standard | Industry Benchmark |

|---|---|---|---|

| Base Material | Epoxy, Polyurethane, Zinc-rich Primer | ISO 12944, ASTM D3359 | Top 3: AkzoNobel, Jotun, Hempel |

| Chemical Resistance | Strong (Acid: 120 hrs, Alkali: 96 hrs, Salt Spray: 1200 hrs) | ISO 9227:2017 | ≥1000 hrs salt spray |

| Hardness (Shore D) | 70-80 | ASTM D2240 | ≥70 |

| Adhesion | Class 1-2 (highest) | ASTM D3359 | Class ≤2 |

| Recommended Dry Film Thickness (DFT) | 80-400 μm (project specific) | ISO 19840 | 100-300 μm |

| Service Life | 15-35 years | ISO 12944-1/2 | ≥20 years in C5-M environment |

| VOC Content | < 250g/L | Regulation (EC) No 1272/2008 | Low-VOC Preferred |

- Material Excellence: Only low-silicon steel (Q355, ASTM A572), precision-cast parts, and forged steel rollers ensure the highest surface protection and mechanical integrity.

- Precision Manufacturing: All major workstations constructed using heavy-gauge, CNC-milled supports, reducing vibration/tolerance stack-up to ≤0.15mm.

- Process Control: Integrated PLC + SCADA for real-time data collection; all spray and curing parameters documented as per ISO 9001 traceability requirements.

- Standards Compliance: Systems designed for ISO 12944, ANSI/AWS D1.1, and CE certification demands.

- Typical Throughput: Up to 40 tons/hour; suitable for massive steel bridge, tower, and industrial structural fabrication.

- Energy-Efficient: VRF-based air recirculation, programmable heater arrays, and minimal overspray ensure lowest operating cost.

| Model | Max Workpiece Size (mm) | Max Load (ton) | Line Speed (m/min) | Painting Chamber Size (mm) | Coating Range | Certifications |

|---|---|---|---|---|---|---|

| YEE-HSPL-36 | 3000 x 3000 x 18000 | 40 | 0.5 ~ 4.2 | 3500 x 3800 x 19000 | 80–400μm | ISO, CE, ANSI |

| YEE-HSPL-28 | 2800 x 2200 x 12000 | 26 | 0.5 ~ 3.1 | 3300 x 2600 x 12500 | 60–300μm | ISO, CE |

| YEE-HSPL-20 | 2200 x 1600 x 8000 | 13 | 0.5 ~ 2.0 | 2400 x 1700 x 8300 | 50–250μm | ISO |

- Automated Coating Uniformity: Ensures consistent dry film thickness, minimizing variation to ≤8μm, and guaranteeing compliance to ISO 19840 coverage requirements.

- Precision Climate Management: Chamber air temp & humidity automatically compensated to ±2°C/±4% RH, eliminating moisture-related blistering.

- Eco-efficiency: Integrated VOC scrubbers and recycling filters exceed EU environmental benchmarks. VOC emission is ≤45mg/m3 (ISO 16000).

- Advanced Defect Detection: High-resolution vision systems automatically flag pinholes, sags, and orange peel surface defects.

| Feature | YEEED Heavy Steel Structure Painting Line | Conventional Line (Brand X) |

|---|---|---|

| Coating Uniformity (DFT σ) | ≤8μm | 18–25μm |

| Max Workpiece Size | 3000 x 3000 x 18000 mm | 1800 x 2000 x 9000 mm |

| Annual Capacity | 120,000 tons | 52,000 tons |

| VOC Emission | ≤45 mg/m³ | 170-200 mg/m³ |

| Standard Compliance | ISO 9001, ISO 12944, ANSI/AWS D1.1 | ISO 12944 (partial) |

| Warranty/Service | 5 Years/24x7 Support | 1 Year/10x5 |

- Industry-tailored Solutions: Fully custom spray/nozzle configuration, PLC logic, chamber layout for unique structures— power transmission towers, urban viaducts, port cranes, LNG plant piping, and more.

- Corrosion Class Targeting: Advanced blast prep and multi-coat design tuned for ISO 12944 C4/C5-M/C5-I, supporting use in desert, marine, and heavy industrial settings.

- Energy Conservation: High-efficiency heat recovery and air recirculation save up to 38% power vs. legacy lines.

- Specifications: 23,000 tons of Q355B steel; max profile 3.0x2.9m

- Solution: YEEED HSPL-36 line; triple-coat (zinc-rich primer + epoxy + PU topcoat); 320μm DFT

- Surface Prep: Robotic shot blasting (Sa2.5) and post-coat non-destructive testing (holiday detection, adhesion, gloss, salt spray)

- Cost Impact: Painting cost $12.7/m2 (35% saving over manual)

- Lifecycle: Warranted maintenance cycle: 30 years (C5-M exposure, ISO 12944-6 certified)

- Reliability: "After upgrading to the YEEED Heavy Steel Structure Painting Line, our annual steel corrosion-related losses dropped by over 95%." – Bridge EPC, Malaysia, 2023

- Ease of Maintenance: "Downtime has reduced from 24 hours/month to less than 2 hours. Remote diagnostics and backup modules are extremely valuable." – Petrochemical Plant, Oman, 2024

- Support: Immediate 24/7 expert support, on-site commissioning, and annual audits ensure system always delivers ISO/ANSI-standard results.

- Delivery Timeline: Standard models: 90–120 days ex-works; Custom/tailored lines: 140–180 days, globally delivered with on-site installation.

- Quality Management: 100% factory testing (coating uniformity, chamber airtightness, PLC/SCADA, full simulation), certified to ISO 9001:2015.

- Warranty: 5-year full component warranty; rust-through and chamber integrity guaranteed in certified countries.

- China & Asia Expertise: Decades of experience, local language teams, remote/onsite service in 15+ countries.

- Post-Sale Support: 24x7 global helpline; annual maintenance, operator training, and preventive audit program included.

- LinkedIn: Trends in Heavy Steel Industry Coatings

- Jotun: Why Structural Coating Choice Matters

- Engineering News: Structural Steel Coatings Challenges (2023)

- ResearchGate: Comparative Analysis of Structural Coating Technologies

- ISOQSLtd: Why ISO 12944 is Important

Content incorporates data and best practices from industry forums, peer-reviewed journals, major market reports, and published project case studies to deliver actionable insights in accordance with EEAT standards.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025