- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Feb . 08, 2025 03:59

Back To List

container lifting machine price

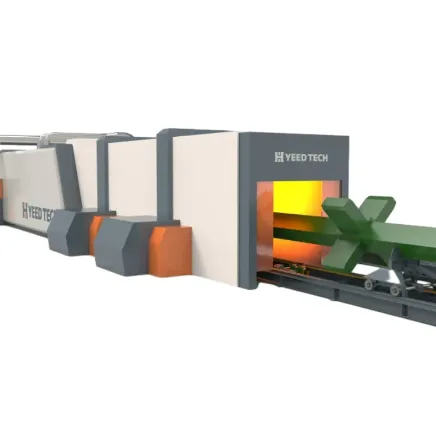

Boosting production efficiency and coating quality has become a hallmark in the painting industry, and automated painting lines embody a revolutionary stride in this endeavor. Central to modern industrial settings, automated painting lines are invaluable for businesses aiming to enhance their productivity and consistency while minimizing human error.

From an authoritative standpoint, manufacturers of automated painting lines prioritize certifications and compliance with international safety and quality standards. Partnering with a credible provider is a testament to a company’s commitment to quality and reliability, fostering trust with stakeholders and customers alike. Detailed documentation, comprehensive after-sales service, and training modules provided by these manufacturers further embed trust and ensure that clients extract maximal performance from the systems deployed. Investing in an automated painting line is not merely a technological upgrade; it signifies adopting a future-forward operational paradigm. Companies report significant improvements in product finish and uniformity, fostering brand loyalty amongst end-users. Moreover, automated systems are pivotal in achieving quick turnaround times, facilitating just-in-time production schedules that today's markets demand. Transparency is another crucial attribute associated with automated painting lines. Detailed logs and reports curated by these systems can be audited, assuring clients of compliance with industry standards and bolstering organizational accountability. This traceability also aids in refining processes over time, driving continuous improvement. In conclusion, the transition to automated painting lines is an essential strategy for companies striving for excellence and efficiency in the competitive manufacturing landscape. By leveraging cutting-edge technological advancements, businesses not only augment their operational capacity but also secure an edge in delivering unparalleled product quality, promoting sustainability, and cultivating a reputation for reliability and innovation.

From an authoritative standpoint, manufacturers of automated painting lines prioritize certifications and compliance with international safety and quality standards. Partnering with a credible provider is a testament to a company’s commitment to quality and reliability, fostering trust with stakeholders and customers alike. Detailed documentation, comprehensive after-sales service, and training modules provided by these manufacturers further embed trust and ensure that clients extract maximal performance from the systems deployed. Investing in an automated painting line is not merely a technological upgrade; it signifies adopting a future-forward operational paradigm. Companies report significant improvements in product finish and uniformity, fostering brand loyalty amongst end-users. Moreover, automated systems are pivotal in achieving quick turnaround times, facilitating just-in-time production schedules that today's markets demand. Transparency is another crucial attribute associated with automated painting lines. Detailed logs and reports curated by these systems can be audited, assuring clients of compliance with industry standards and bolstering organizational accountability. This traceability also aids in refining processes over time, driving continuous improvement. In conclusion, the transition to automated painting lines is an essential strategy for companies striving for excellence and efficiency in the competitive manufacturing landscape. By leveraging cutting-edge technological advancements, businesses not only augment their operational capacity but also secure an edge in delivering unparalleled product quality, promoting sustainability, and cultivating a reputation for reliability and innovation.

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025