Structural Coating: Durable Protection, Cost-Effective Solutions

Advancing Industrial Protection: The Power of Modern Structural Coating Technologies

In the realm of heavy industry and infrastructure, the longevity and integrity of steel structures are paramount. Exposure to harsh environmental elements, corrosive agents, and extreme temperatures necessitates robust protection systems. This is where structural coating emerges as a critical defense mechanism, extending the operational life of assets, reducing maintenance costs, and ensuring operational safety. Modern industrial sectors, including petrochemicals, energy, marine, and construction, rely heavily on advanced coating solutions to safeguard their monumental investments. The evolution of coating materials, from traditional paints to sophisticated polymer and composite formulations, reflects a growing demand for superior performance characteristics such as enhanced adhesion, chemical resistance, abrasion durability, and UV stability. Furthermore, with an increasing global emphasis on sustainability, the development of eco-friendly and low-VOC coating systems is gaining significant traction, driving innovation within the industry. Companies are seeking not just protective layers but comprehensive solutions that integrate seamlessly into their manufacturing and maintenance cycles, providing long-term value and compliance with stringent environmental regulations, thereby fortifying the backbone of global industrial operations against the relentless forces of degradation and time.

The industrial landscape is continuously evolving, marked by a dynamic interplay of technological advancements and stringent regulatory frameworks. Key trends shaping the future of industrial coatings include the adoption of smart coatings with self-healing properties, the integration of IoT for real-time performance monitoring, and the widespread implementation of automated application systems like the modern spray painting line. These innovations collectively aim to enhance application efficiency, reduce material waste, and improve the overall quality and consistency of the applied protective layers. Businesses are increasingly recognizing that the initial investment in high-quality structural coating solutions is vastly outweighed by the long-term savings accrued from corrosion prevention, reduced downtime, and extended asset lifespan. This proactive approach to asset management is crucial for industries where infrastructure failure can lead to catastrophic consequences, both in terms of financial losses and environmental impact. Therefore, understanding the nuances of coating technologies, their application methodologies, and their long-term performance benefits is indispensable for B2B decision-makers and technical personnel aiming to optimize their operational integrity and secure their capital expenditures, ultimately ensuring resilience and profitability in an increasingly demanding global market, while carefully managing the total lifecycle cost, including the crucial structural steel painting cost.

Precision and Efficiency: Introducing the Heavy Steel Structure Painting Line

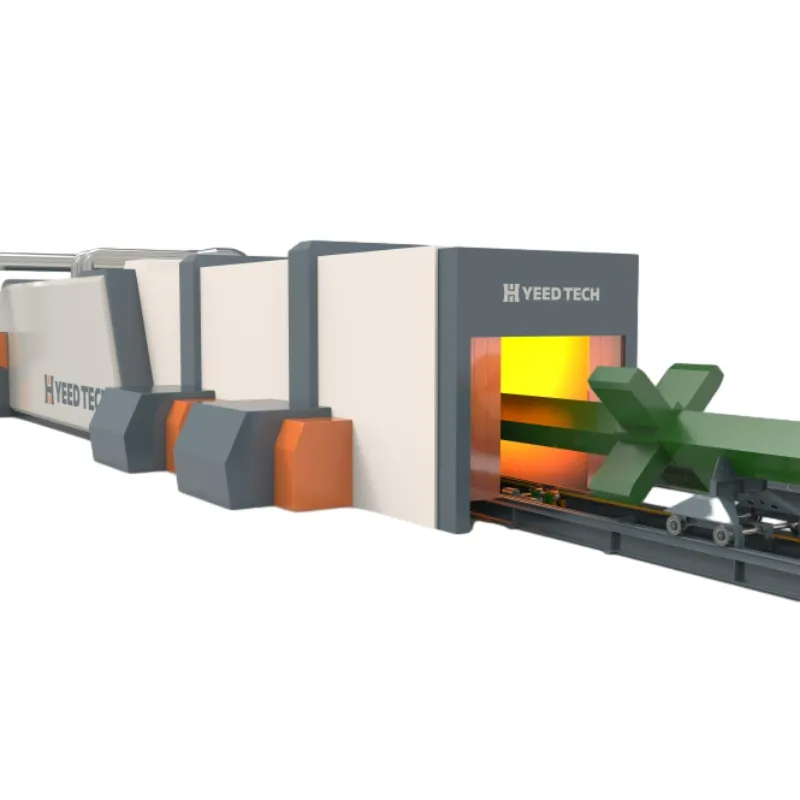

The application of high-performance structural coating demands precision, consistency, and an efficient operational framework. Our flagship product, the Heavy Steel Structure Painting Line, is engineered to meet these exacting requirements, offering a state-of-the-art solution for comprehensive steel structure protection. This advanced system integrates various stages of the coating process, from initial surface preparation to final curing, ensuring optimal adhesion and durability of the applied coating. Designed specifically for large and complex steel components, this painting line minimizes manual intervention, significantly reducing potential human error and improving safety standards within industrial environments. The automated nature of the line ensures uniform coating thickness, critical for achieving the desired level of corrosion resistance and extending the service life of structures in demanding applications such as offshore platforms, bridge frameworks, and large industrial machinery. The integration of intelligent control systems allows for real-time monitoring and adjustment of parameters, ensuring consistent quality across diverse production batches and enabling precise control over material consumption, which directly impacts the overall structural steel painting cost by optimizing resource utilization and minimizing waste throughout the extensive application process.

At the core of the Heavy Steel Structure Painting Line's efficacy is its ability to handle a wide range of structural steel profiles and sizes, adapting seamlessly to varying project specifications. This versatility makes it an invaluable asset for fabrication yards, shipyards, and large-scale manufacturing facilities that regularly handle structures produced via casting, forging, or intricate CNC machining, all of which require meticulous surface treatment prior to coating. The line’s design prioritizes both throughput and coating quality, utilizing advanced spray technology, precise environmental controls, and efficient drying systems. For example, optimized air circulation and temperature control within curing ovens accelerate the drying process, reducing overall production cycles without compromising coating integrity. Furthermore, the system is built with modularity in mind, allowing for customization and scalability to meet specific client needs and future expansion plans. This adaptability, combined with robust construction and a focus on operational longevity, positions our Heavy Steel Structure Painting Line as a leading solution for businesses seeking to elevate their protective coating capabilities. The integrated approach of our spray painting line ensures that every inch of a steel structure receives optimal protection, mitigating risks and securing long-term operational excellence, thereby significantly impacting the total cost of ownership over the asset's lifecycle by enhancing durability and reducing the need for premature recoating interventions.

The Comprehensive Process Flow of Structural Coating Application

The successful application of a structural coating is a multi-stage process, each step critical to achieving optimal adhesion, durability, and protective performance. It typically begins with rigorous surface preparation, which is arguably the most vital stage, accounting for a significant portion of the total structural steel painting cost but crucial for coating longevity. This often involves blast cleaning, such as grit blasting or shot blasting, to remove rust, mill scale, old coatings, and other contaminants, creating a clean, roughened profile (e.g., SA 2.5 or SA 3.0 as per ISO 8501-1) essential for mechanical keying of the coating. Following blasting, dust and debris are meticulously removed, often by vacuum or compressed air, to prevent contamination that could compromise adhesion. Materials processed typically include various grades of carbon steel, alloy steel, and even certain stainless steels requiring protective layers. Manufacturing processes of the structures themselves, such as welding, forging, or CNC machining, necessitate specific pre-treatment protocols to address residual stresses or surface imperfections. Each element, regardless of its original manufacturing method, must meet stringent inspection standards like ISO 12944 for corrosion protection or ANSI standards for specific industrial applications, ensuring the substratum is perfectly prepared for coating application and maximum long-term performance.

Once the surface is prepared, the steel structures enter the advanced spray painting line. This is where the chosen structural coating system, comprising primers, intermediate coats, and topcoats, is precisely applied. Application methods vary depending on coating type and structure complexity but commonly include airless spray, conventional spray, or automated robotic systems to ensure uniform thickness and coverage. For instance, in petrochemical facilities, where exposure to chemicals and high temperatures is common, multi-layer epoxy or polyurethane coatings are often applied, whereas in the metallurgy sector, specialized coatings might offer extreme heat or abrasion resistance. After application, the coating undergoes a carefully controlled curing process, which can involve forced air drying, infrared heating, or natural ambient curing, depending on the coating's chemistry (e.g., solvent-borne, water-borne, or 100% solids) and the desired curing time. Post-curing, thorough inspection is conducted, employing tools like dry film thickness (DFT) gauges, adhesion testers (pull-off tests), and holiday detectors to identify pinholes or discontinuities. The expected service life of such coated structures can extend significantly, often 15-25 years or more, providing critical anti-corrosion and energy-saving benefits by maintaining structural integrity and thermal efficiency in applications ranging from pipelines in oil and gas to large water infrastructure in give-and-drainage systems, demonstrating a clear return on the initial investment.

Technical Parameters & Performance of Advanced Structural Coatings

The efficacy of a structural coating is quantified by a range of technical parameters that dictate its performance under specific environmental and operational conditions. Understanding these metrics is crucial for B2B decision-makers to select the most appropriate coating system for their assets, ensuring optimal protection and cost-effectiveness over the lifespan of the structure. Key parameters include dry film thickness (DFT), which is directly correlated with protective capability; adhesion strength, measured in PSI or MPa (per ASTM D4541), indicating how well the coating bonds to the substrate; and hardness, typically measured using Shore D or Pencil Hardness scales (e.g., ASTM D3363), reflecting resistance to abrasion and impact. Furthermore, chemical resistance to acids, alkalis, solvents, and other aggressive substances is critical for industrial environments like chemical processing plants or wastewater treatment facilities, where exposure to harsh chemicals is routine. Temperature resistance, both continuous and intermittent, defines the operational limits of the coating, especially pertinent for high-temperature applications in power generation or steel mills. The ultimate goal is to minimize structural steel painting cost by maximizing coating longevity and performance, thereby reducing future maintenance interventions and ensuring long-term asset integrity under diverse environmental stressors.

Beyond these fundamental properties, advanced structural coating formulations offer specialized characteristics such as flexibility to accommodate structural movement (evaluated via conical mandrel bend test, ASTM D522), UV resistance for outdoor exposure, and anti-graffiti or self-cleaning properties for aesthetic maintenance. For instance, specific coatings designed for marine environments exhibit superior salt spray resistance (ASTM B117 standards, often exceeding 2000 hours without significant degradation) and resistance to cathodic disbondment, crucial for submerged structures. The coefficient of friction, critical for applications involving moving parts, and dielectric strength for electrical insulation purposes, are also relevant in niche scenarios. Data from accelerated weathering tests (e.g., QUV, Xenon Arc per ASTM G154/G155) provide insights into long-term durability, simulating years of environmental exposure in a condensed timeframe. By analyzing these parameters, companies can precisely tailor their coating specifications to the unique demands of their projects, from minimizing corrosion in demanding offshore structures to providing a durable, aesthetically pleasing finish on architectural steel. This meticulous selection process, combined with precise application via a robust spray painting line, ensures that the asset receives protection that is not only effective but also economically viable for its entire projected service life.

Typical Structural Coating Performance Parameters

| Parameter | Measurement Unit/Standard | Typical Range (Epoxy/Polyurethane) | Significance |

|---|---|---|---|

| Dry Film Thickness (DFT) | Microns (µm) / Mil (ASTM D7091) | 150 - 400 µm (6 - 16 mil) per coat | Primary barrier against corrosion, directly impacts longevity and protective efficacy. |

| Adhesion Strength | PSI / MPa (ASTM D4541) | > 500 PSI (> 3.5 MPa) | Crucial for preventing delamination; dictates bond to substrate under stress. |

| Pencil Hardness | H - 3H (ASTM D3363) | 2H - 3H | Resistance to scratching, marring, and light abrasion. |

| Flexibility (Conical Mandrel) | Pass/Fail (ASTM D522) | > 25% elongation (Pass) | Ability to withstand substrate movement or deformation without cracking. |

| Corrosion Resistance (Salt Spray) | Hours (ASTM B117) | > 2000 hours without significant rust/blistering | Simulates corrosive environments; key for marine/coastal and high-humidity applications. |

| Temperature Resistance | °C / °F (ASTM D2485) | -30°C to 120°C (-22°F to 248°F) | Maximum operating temperature range without degradation of protective properties. |

| VOC Content | g/L (EPA Method 24) | < 100 g/L (low VOC) | Environmental impact and compliance with stringent emissions regulations. |

Diverse Application Scenarios and Industry Impact

The versatility of structural coating solutions, applied efficiently through a modern spray painting line, makes them indispensable across a multitude of heavy industrial sectors. In the petrochemical industry, where assets like storage tanks, pipelines, and refinery structures are constantly exposed to corrosive chemicals, extreme temperatures, and harsh outdoor conditions, specialized coatings provide crucial protection against chemical attack and atmospheric corrosion, significantly extending operational life and preventing costly leaks or failures. For the metallurgy sector, including steel mills and foundries, coatings must withstand extreme heat, abrasion from material handling, and aggressive dust environments. Here, intumescent coatings offer fire protection, while anti-abrasion coatings protect vital machinery, contributing to operational safety and reducing equipment replacement frequency. The give-and-drainage sector, encompassing water treatment plants, pumping stations, and large diameter pipes, relies on coatings to prevent corrosion from water and wastewater, ensuring hygienic conditions and structural integrity, while reducing the overall structural steel painting cost over time by minimizing the need for frequent repairs and replacements due to water-induced degradation.

Beyond these core industries, structural coating plays a pivotal role in infrastructure projects such as bridges, port facilities, and power transmission towers, where long-term durability against environmental elements like humidity, UV radiation, and salt spray is paramount. In the marine industry, ship hulls and offshore oil rigs benefit immensely from advanced anti-corrosion and anti-fouling coatings that reduce drag, improve fuel efficiency, and minimize bio-fouling, directly contributing to energy saving and operational cost reduction. These coatings not only safeguard structural assets but also contribute significantly to environmental protection by preventing hazardous substance releases due to corrosion-induced failures, such as leaks in pipelines carrying hazardous materials. By ensuring the structural integrity of critical assets, these advanced coatings mitigate risks, enhance safety, and optimize operational efficiency, demonstrating a clear return on investment far beyond the initial coating application expense. The ability to customize coating systems for specific environmental challenges and apply them consistently with automated painting lines allows industries to achieve superior protection and compliance with stringent international standards, underscoring the vital impact of this technology on global industrial resilience and sustainable development.

Manufacturer Comparison, Customization, and Unmatched Service

When selecting a partner for a Heavy Steel Structure Painting Line and robust structural coating solutions, a thorough manufacturer comparison is essential, extending beyond initial purchase price to encompass long-term value, technological innovation, and comprehensive support. Our commitment to excellence distinguishes us in a competitive landscape, offering not just cutting-edge equipment but also unparalleled expertise gained from years of industry leadership. While many providers offer standard painting lines, our unique advantage lies in our deep understanding of various industrial applications and our capacity for extensive customization. We recognize that no two projects are identical; thus, our solutions are meticulously tailored to specific client needs, considering factors such as required throughput, size and complexity of steel structures (e.g., I-beams, trusses, complex assemblies produced via forging or casting), environmental regulations, and specific coating types (e.g., zinc-rich primers, epoxy intermediates, polyurethane topcoats). This bespoke approach ensures that clients receive a system perfectly optimized for their operational demands, maximizing efficiency and minimizing the structural steel painting cost per unit by aligning technology precisely with production goals and material specifications.

Our service capabilities extend far beyond system installation, embodying a true partnership approach. We provide comprehensive technical support, operator training, and ongoing maintenance services to ensure uninterrupted operation and maximum system uptime for every spray painting line. This proactive support model is designed to optimize the performance and longevity of your investment, effectively minimizing potential disruptions and maximizing productivity. Furthermore, our dedication to client success is underscored by our adherence to international quality standards, holding certifications such as ISO 9001 for quality management and environmental compliance, ensuring that every product and service adheres to the highest benchmarks. We pride ourselves on transparent communication, flexible scheduling, and rapid response times for technical queries or operational assistance, building long-term relationships based on trust and mutual success. Choosing us means partnering with a leader committed to delivering superior performance, innovative solutions, and unwavering support for your most critical industrial coating requirements, guaranteeing a robust and reliable system for your heavy steel structures while ensuring compliance with global regulatory frameworks and optimizing your overall operational expenditure.

Real-World Case Studies and Customer Success

Our Heavy Steel Structure Painting Lines have been instrumental in delivering superior structural coating solutions across diverse industries, leading to significant enhancements in asset durability and operational efficiency for our clients worldwide. A prominent example includes a major shipyard that integrated our automated spray painting line to process large vessel components. Prior to installation, their manual coating process resulted in inconsistent film thicknesses, extended lead times, and high material waste, contributing significantly to their overall structural steel painting cost. Post-implementation, the shipyard reported a 30% reduction in coating material consumption due to precise robotic application, a 40% improvement in throughput, and a dramatic increase in coating uniformity, resulting in extended dry dock intervals for their vessels and substantial long-term maintenance savings. This quantifiable success underscores the direct correlation between advanced painting line technology and tangible economic benefits, demonstrating our commitment to delivering solutions that positively impact our clients' bottom line and operational capabilities in the highly competitive marine sector.

Another compelling case involves a large-scale infrastructure project focused on bridge construction in a highly corrosive coastal environment. The client faced challenges in achieving long-term corrosion protection for massive steel bridge sections using conventional methods, which proved inadequate for the expected service life and demanding conditions. Our customized painting line, equipped with specialized environmental controls and multi-axis robotic sprayers, enabled the consistent application of a multi-layer high-performance structural coating system, tailored for severe marine exposure, including splash zones and atmospheric attack. The result was a coating system exhibiting exceptional adhesion and corrosion resistance, verified by third-party adhesion (ASTM D4541) and salt spray (ASTM B117) tests, projected to extend the bridge's service life by an additional 15 years beyond typical expectations, significantly reducing future repair and recoating expenditures. These success stories are a testament to our ability to deliver not just machinery, but complete, high-value solutions that address critical industrial challenges, providing our clients with a distinct competitive advantage and ensuring the integrity and longevity of their most vital assets in challenging operational landscapes. The positive feedback and repeat business from these and numerous other clients exemplify our commitment to delivering verifiable results and fostering enduring partnerships built on performance and reliability.

Ensuring Quality: Certifications, Standards, and Trust

In the high-stakes world of industrial asset protection, trust is built on verifiable quality, adherence to international standards, and robust assurances. Our Heavy Steel Structure Painting Line and the structural coating processes it facilitates are underpinned by rigorous quality management systems. We proudly maintain ISO 9001 certification, a globally recognized standard for quality management, ensuring that every stage of design, manufacturing, installation, and after-sales service meets the highest benchmarks for consistency and customer satisfaction. Furthermore, our operations and the output quality of our spray painting line comply with relevant industry-specific standards such as ISO 12944 for corrosion protection of steel structures by protective paint systems, and ANSI/NACE standards for surface preparation and coating application in specific industrial environments (e.g., NACE SP0108). These certifications are not merely badges; they represent our unwavering commitment to producing reliable, high-performance systems and coatings that meet or exceed industry expectations, ultimately mitigating risks for our clients and providing them with peace of mind regarding their long-term investments and the overall structural steel painting cost over the life of the asset by ensuring prolonged durability and reducing unscheduled maintenance.

To further cultivate trust, we offer comprehensive documentation including detailed testing protocols and performance data for our coating systems, alongside transparent warranty commitments and clear delivery schedules. Our products undergo stringent factory acceptance tests (FAT) before shipment, where clients can witness the system's operational capabilities and confirm adherence to specifications. On-site acceptance tests (SAT) are conducted post-installation to ensure optimal functionality within the client's operational environment. The typical delivery cycle for a custom Heavy Steel Structure Painting Line ranges from 12 to 24 weeks, depending on complexity and customization, with clear milestones communicated throughout the project life cycle, ensuring transparent project management. We provide a standard warranty of 1-2 years on equipment components and workmanship, with extended service agreements available for long-term operational assurance, tailored to client needs. Our dedicated customer support team is available for technical assistance, troubleshooting, and spare parts procurement, ensuring minimal downtime. This holistic approach, from design to post-sale support, demonstrates our unwavering commitment to providing trusted, high-quality industrial coating solutions that stand the test of time and meet the critical needs of B2B enterprises globally, fostering long-term partnerships built on reliability and performance.

Addressing Key Concerns: FAQs & Dedicated Support

Understanding the complexities of industrial structural coating and its application via sophisticated systems can often lead to specific inquiries from B2B clients. We've compiled a list of frequently asked questions to provide clarity and demonstrate our comprehensive support framework. Our goal is to ensure that every aspect, from technical specifications to logistics and maintenance, is transparent and fully understood, bolstering confidence in our solutions and services. For example, common questions often revolve around the adaptability of the Heavy Steel Structure Painting Line to different coating types; our answer consistently highlights its compatibility with a wide array of industrial coatings, including epoxies, polyurethanes, zinc primers, and even specialized fire-retardant or anti-corrosion compounds, ensuring maximum versatility for diverse project requirements. Another frequent query concerns throughput capabilities, where we emphasize our modular design allowing for scaling production capacity to match specific project demands, thereby optimizing the overall structural steel painting cost by balancing speed and quality, and avoiding bottlenecks in large-scale fabrication processes while maintaining stringent quality control measures throughout the entire coating process cycle.

Clients also frequently inquire about the level of automation and required operator skill for the spray painting line. Our systems are designed for intuitive operation with advanced human-machine interfaces (HMIs) and integrated diagnostic tools, minimizing the need for highly specialized operators post-training, thus reducing long-term labor costs. Comprehensive training programs, covering operation, basic maintenance, and troubleshooting, are provided as an integral part of our service package, equipping client personnel with the necessary expertise. Regarding post-installation support, our dedicated technical team is reachable through multiple channels, including phone, email, and remote diagnostics, for rapid response to any operational queries or troubleshooting needs, ensuring minimal disruption to production schedules. We offer various service level agreements (SLAs) for ongoing maintenance and preventative checks, ensuring peak performance and extended equipment life, tailored to the criticality of the client's operations. The typical delivery cycle for standard components and critical spare parts is expedited to minimize downtime, acknowledging the critical nature of continuous industrial operations. This proactive and responsive support model ensures that our clients receive not just a product, but a complete ecosystem of solutions and services designed to maximize their investment in robust structural coating applications and maintain seamless operational flow for decades.

Conclusion: Securing Assets with Advanced Structural Coating

In an era where industrial infrastructure faces escalating challenges from environmental degradation, operational stresses, and the imperative for sustainable practices, the role of high-performance structural coating has never been more critical. These advanced protective layers, meticulously applied through sophisticated systems like the Heavy Steel Structure Painting Line, are fundamental to preserving capital assets, ensuring operational continuity, and mitigating significant financial and environmental risks. From preventing catastrophic corrosion in offshore oil rigs to safeguarding the integrity of critical components in chemical processing plants, the strategic deployment of superior coatings translates directly into enhanced safety, reduced maintenance expenditure, and extended asset longevity, yielding a substantial return on investment. The ongoing innovation in coating materials, coupled with advancements in automated application technologies such as the modern spray painting line, ensures that industries have access to increasingly effective and efficient solutions for their protective needs, thereby optimizing the long-term structural steel painting cost and maximizing overall operational efficiency through reduced downtime and improved asset performance over their entire lifecycle.

The comprehensive benefits of investing in a state-of-the-art coating system extend beyond mere asset protection. They encompass improved energy efficiency through optimized surface properties, compliance with evolving environmental regulations, and the ability to maintain peak operational performance even in the most aggressive industrial settings. As industries continue to strive for greater resilience and sustainability, the importance of robust and reliable structural coating solutions, applied with precision and efficiency, will only grow. Partnering with an experienced and authoritative provider that offers customizable, high-quality painting lines and extensive technical support is paramount to securing your industrial assets for decades to come, ensuring both operational excellence and a sustainable future through reduced environmental impact and prolonged asset utility.

References

- NACE International. (2018). NACE SP0108-2018, Corrosion Control of Steel Structures by Protective Coatings.

- ISO 12944-1:2017. Paints and varnishes — Corrosion protection of steel structures by protective paint systems — Part 1: General introduction.

- ASTM International. (2020). ASTM D4541 - Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers.

- Smith, R. (2019). Industrial Coatings: Fundamentals and Applications. Materials Science Publishing.

- Jones, D. A. (2017). Principles and Prevention of Corrosion. Pearson Education.

Products Categories

Latest News

-

Unveiling the World of Container Handling Equipment in the Marketplace

NewsAug.27,2025 -

Unlocking the Potential of Container Lifting Equipment

NewsAug.27,2025 -

Essential Equipment in Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Efficient Solutions for Shipping Container Manipulation

NewsAug.27,2025 -

Efficient Solutions for Container Handling: Equipment Insights

NewsAug.27,2025 -

Efficient Solutions for Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Welding Fume Composition Analysis

NewsAug.26,2025