Durable Structural Coating | Expert Spray Painting & Steel Protection

Optimizing Heavy Steel Structure Protection with Advanced Coating Solutions

In the realm of industrial infrastructure, the longevity and integrity of heavy steel structures are paramount. These critical assets are constantly exposed to harsh environmental factors, ranging from corrosive chemicals and extreme temperatures to relentless abrasion. Ensuring their durability and preventing premature degradation necessitates robust protective measures. This is where advanced structural coating systems become indispensable. These specialized coatings are engineered to create a resilient barrier, significantly extending the service life of steel components and safeguarding substantial investments. They play a pivotal role across various sectors, from oil and gas to marine and construction, underscoring their importance in modern industrial applications.

The strategic application of high-performance coatings is not merely about aesthetics; it's a critical engineering decision that impacts operational safety, maintenance costs, and overall project economics. Integrating a sophisticated Heavy Steel Structure Painting Line into manufacturing or fabrication processes ensures uniform, high-quality application, which is crucial for achieving optimal protection. Such integrated systems address the challenges of scale and precision, delivering consistent results that manual processes cannot reliably replicate. Understanding the intricacies of these protective systems, from material science to application methodologies, is key for B2B decision-makers seeking long-term value and reliability for their structural assets.

The Comprehensive Process of Structural Coating Application

The application of a durable structural coating is a multi-stage process, meticulously designed to ensure maximum adhesion, coverage, and protective performance. This comprehensive approach begins long before the coating is actually applied, focusing on meticulous surface preparation. Typically, this involves abrasive blast cleaning (e.g., SA 2.5 or SA 3.0 standards) to remove rust, mill scale, and other contaminants, creating an optimal surface profile for coating adhesion. This step is critical, as up to 80% of coating failures can be attributed to inadequate surface preparation. Following blasting, the steel structure may undergo degreasing and dust removal to ensure a pristine substrate.

Once the surface is prepared, the actual coating application commences. Modern facilities often utilize advanced `spray painting line` technology, which provides superior efficiency and uniformity compared to manual methods. This can involve automated robotic sprayers or high-volume airless spray guns for large structures. Depending on the specific requirements, multiple layers of structural coating are applied, including primers for adhesion and corrosion inhibition, intermediate coats for build-up and additional protection, and topcoats for UV resistance, chemical resistance, and aesthetic finish. Common materials include epoxy, polyurethane, zinc-rich primers, and various fluoropolymer formulations, each selected based on the anticipated service environment and performance criteria.

Post-application, the coating undergoes a crucial curing or drying phase, which can be ambient air drying, forced air drying, or oven curing depending on the coating chemistry. This process allows the coating to cross-link and achieve its full mechanical and chemical properties. Throughout this entire sequence, rigorous quality control checks are implemented. These include measuring dry film thickness (DFT), adhesion testing (e.g., pull-off or cross-cut tests), visual inspection for defects, and holiday detection (pinhole testing) to ensure barrier integrity. Compliance with international standards such as ISO 12944 (for corrosion protection), ANSI, and ASTM (e.g., ASTM D3359 for adhesion) is strictly maintained to guarantee the highest quality and extend the service life of the coated structures to often 20+ years in C5-M corrosive environments.

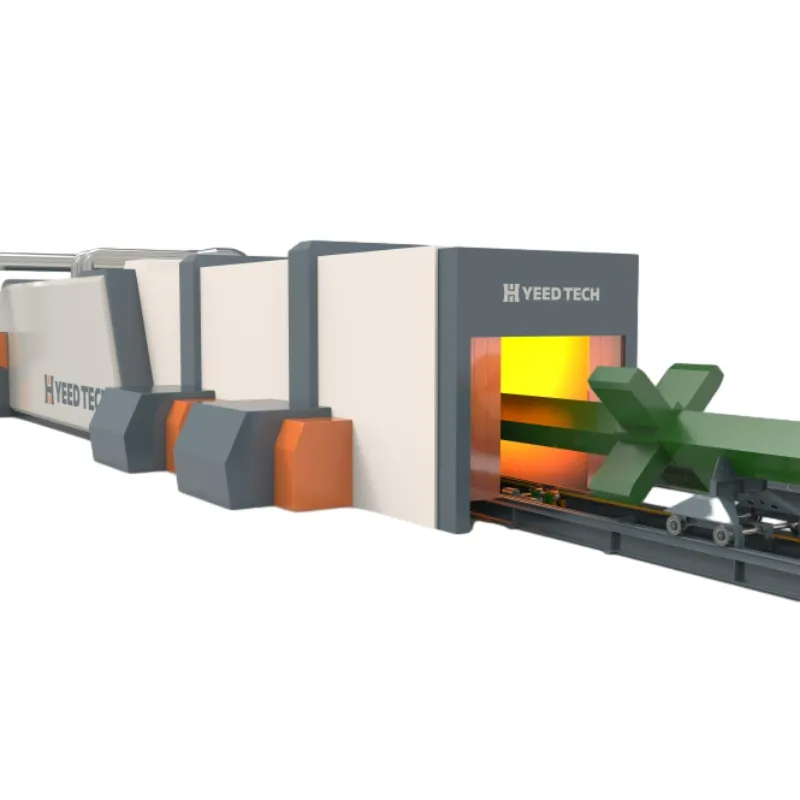

Figure 1: Automated structural coating application in a modern painting line.

Key Technical Parameters and Industry Performance Benchmarks

The selection and application of a structural coating involve a deep understanding of its technical specifications and how they align with project requirements and environmental conditions. Performance metrics are crucial for ensuring the chosen coating system delivers the expected durability and protection. Below is a table outlining typical parameters for high-performance structural coating systems, often used in heavy industry:

These parameters are not static; they vary significantly based on the specific type of structural coating (e.g., epoxy, polyurethane, zinc-rich primer) and its intended application. For instance, coatings for submerged structures in marine environments will prioritize water resistance and cathodic disbondment, while those for chemical processing plants will emphasize chemical resistance. Manufacturers like Yeeeed adhere to stringent quality control protocols, leveraging in-house testing facilities and third-party certifications (e.g., ISO 9001 for quality management systems) to validate these performance claims. This commitment to data-driven performance ensures that the investment in a high-quality structural coating system translates into verifiable asset protection and reduced lifecycle costs, a critical consideration when evaluating the total `structural steel painting cost`.

Diverse Application Scenarios and Tangible Advantages

The versatility of structural coating solutions makes them indispensable across a multitude of heavy industries. In the petrochemical sector, for example, coatings protect pipes, storage tanks, and structural supports from highly corrosive chemicals, acids, and alkalis, ensuring operational safety and environmental compliance. For metallurgy and mining, robust coatings defend against abrasion from ore, dust, and aggressive slurries, minimizing wear and tear on heavy machinery and conveyors. In the realm of infrastructure, including bridges, power plants, and public utilities, advanced coatings provide critical protection against atmospheric corrosion, UV radiation, and extreme weather, significantly extending the lifespan of these vital assets. Even in specialized fields like wastewater treatment and water supply, specific anti-corrosive and anti-fouling structural coating systems safeguard equipment and pipelines from microbial growth and corrosive aqueous environments, ensuring clean water delivery and efficient system operation.

The advantages of implementing a high-quality structural coating system are multi-faceted and directly impact a project's bottom line. Primarily, corrosion prevention is paramount. By forming an impenetrable barrier, coatings prevent the electrochemical reactions that lead to rust and material degradation, thereby preserving structural integrity. This directly translates into extended asset service life, often doubling or tripling the operational period before major maintenance or replacement is required. Furthermore, coatings contribute to significant energy savings; for instance, specialized insulating coatings can reduce heat loss from pipelines or storage tanks, optimizing energy efficiency in thermal processes. Beyond this, enhanced durability reduces the frequency of costly repairs and downtime, lowering overall maintenance expenditure. For large-scale projects, especially those involving extensive steel fabrication, the efficiency and consistency offered by an automated `spray painting line` are invaluable, ensuring that project timelines are met and quality standards are consistently maintained, directly influencing the overall `structural steel painting cost` efficiency.

Tailored Solutions and Client Success Stories

Recognizing that no two industrial projects are identical, leading providers like Yeeeed specialize in crafting customized structural coating solutions. This involves a comprehensive assessment of the client's specific operational environment, the type of steel structure, anticipated corrosive factors, and budget constraints. Based on this, a bespoke coating system, including the selection of appropriate materials and application methodology, is designed. For instance, a client requiring protection for offshore platforms will receive a different multi-coat system, focusing on marine-grade durability, compared to a client needing interior structural protection within a manufacturing plant, where chemical resistance might be the priority. Our technical teams collaborate closely with clients, from initial consultation to installation and ongoing support, ensuring the deployed solution is perfectly aligned with their long-term asset protection goals and optimized `structural steel painting cost`.

Our commitment to client success is underpinned by rigorous quality assurance and transparent service. We understand that investing in a Heavy Steel Structure Painting Line is a strategic decision for manufacturers and fabricators. Our systems are built to ISO 9001 standards, ensuring consistent quality and reliability. Client feedback consistently highlights the efficiency gains and superior finish quality achieved with our structural coating lines. For example, a recent project for a major fabrication company specializing in bridges reported a 30% reduction in coating time and a 15% decrease in material waste after implementing our automated `spray painting line`. This not only improved their production throughput but also enhanced the long-term durability of the coated bridges, cementing their reputation for quality infrastructure. Our service record, spanning over two decades in the industry, speaks to our expertise and dependability in delivering high-performance painting solutions worldwide.

Figure 2: Heavy Steel Structure Painting Line ensuring consistent structural coating quality.

Frequently Asked Questions (FAQs)

-

Q: What is the typical service life expected from a high-quality structural coating?

A: With proper surface preparation and application of a multi-coat system adhering to standards like ISO 12944, a structural coating can provide corrosion protection for 15-25 years or even longer, depending on the corrosive environment (e.g., C3, C4, C5-I, C5-M classifications) and coating type. Regular inspection and localized touch-ups can further extend this lifespan.

-

Q: How does a `spray painting line` reduce `structural steel painting cost`?

A: An automated `spray painting line` significantly reduces labor costs, material waste due to overspray control, and accelerates production cycles. Its consistent application quality minimizes rework and extends the life of the coating, leading to lower long-term maintenance expenses. While initial setup costs may be higher than manual methods, the long-term ROI is substantial for high-volume operations.

-

Q: What kind of warranty and customer support do you offer for your painting lines?

A: We typically offer a standard 12-24 month warranty on our Heavy Steel Structure Painting Line components and workmanship. Beyond the warranty period, we provide comprehensive after-sales support, including spare parts availability, remote technical assistance, and on-site maintenance services globally. Our goal is to ensure continuous, optimal operation of your structural coating facility.

-

Q: What are the typical delivery and installation timelines for a custom painting line?

A: Delivery and installation timelines vary based on the complexity and customization of the Heavy Steel Structure Painting Line. Generally, fabrication and shipping can take 60-120 days, followed by 30-60 days for on-site installation and commissioning. A detailed project timeline is provided after the initial design and specification phase, ensuring transparency and efficient project management for your structural coating setup.

References and Further Reading

- ISO 12944-1:2017, Paints and varnishes – Corrosion protection of steel structures by protective paint systems – Part 1: General introduction.

- ASTM D3359 / D3359M-17, Standard Test Methods for Measuring Adhesion by Tape Test.

- NACE International Publication 02106, Coatings and Linings for Corrosion Control of Steel in Immersion Service.

- The Society for Protective Coatings (SSPC), Various standards for surface preparation and coating application.

Products Categories

Latest News

-

Unveiling the World of Container Handling Equipment in the Marketplace

NewsAug.27,2025 -

Unlocking the Potential of Container Lifting Equipment

NewsAug.27,2025 -

Essential Equipment in Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Efficient Solutions for Shipping Container Manipulation

NewsAug.27,2025 -

Efficient Solutions for Container Handling: Equipment Insights

NewsAug.27,2025 -

Efficient Solutions for Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Welding Fume Composition Analysis

NewsAug.26,2025