Automatic Paint Spraying Machine: Precision, Speed & Quality

Advancing Industrial Efficiency with Automatic Paint Spraying Technology

In today’s competitive manufacturing landscape, the pursuit of precision, consistency, and unparalleled efficiency drives innovation. At the forefront of this industrial evolution is the automatic paint spraying machine, a pivotal technology transforming how industries approach surface finishing. These sophisticated systems move beyond manual application, offering a revolutionary leap in productivity, material utilization, and coating quality across diverse sectors. From heavy steel structures to intricate automotive components, the integration of an automatic paint dispenser is synonymous with optimized production lines and superior end-product aesthetics and durability. The adoption of an automated painting process not only mitigates human error and reduces labor costs but also ensures uniform film thickness and enhanced corrosion resistance, critical for products designed for long service life in demanding environments. Our focus on engineering excellence ensures that each automatic spray painting system we develop is a testament to reliability, precision, and long-term value, directly contributing to our clients' operational goals and market leadership. The shift towards automated solutions reflects a broader industry trend emphasizing sustainable practices, minimizing Volatile Organic Compound (VOC) emissions, and maximizing transfer efficiency, making intelligent coating solutions an indispensable asset for modern manufacturing facilities aiming for peak performance and environmental responsibility.

Precision Engineering: The Manufacturing Process of Automatic Paint Spraying Machines

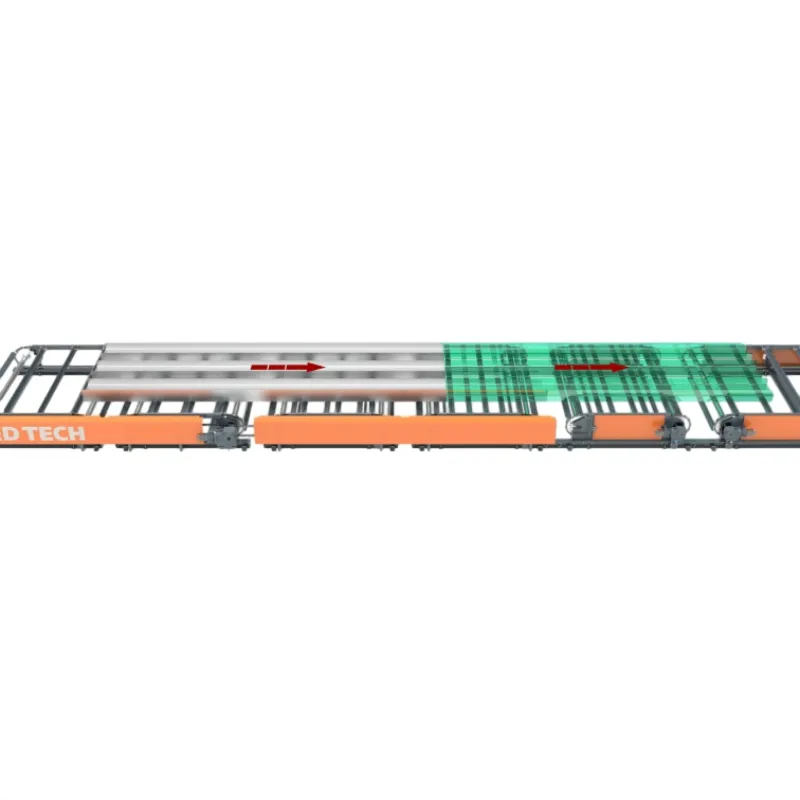

The creation of a high-performance automatic paint spraying machine is a meticulous process demanding stringent quality control and advanced manufacturing techniques, ensuring its reliability and longevity in arduous industrial environments. Every component, from the robotic arm and high-pressure pumps to the precision nozzles, undergoes rigorous fabrication. We begin with the selection of premium materials, such as high-grade stainless steel (e.g., SUS304 or SUS316 for fluid passages to resist corrosion from various coatings) and specialized aluminum alloys for lightweight yet robust structural components. Manufacturing processes include precision casting for intricate fluid delivery systems, ensuring smooth flow and minimal pressure drop. Advanced CNC machining is extensively utilized for producing critical components like robotic arm joints, nozzle bodies, and pump housings, guaranteeing micron-level tolerances essential for consistent spray patterns and high transfer efficiency. For the machine's framework, laser cutting and robotic welding ensure structural integrity and dimensional accuracy. Each stage is complemented by comprehensive detection standards, including ISO 9001 for quality management, ANSI standards for safety and performance, and CE certifications for European market compliance. These machines are engineered for an extended service life, typically exceeding 15-20 years with proper maintenance, due to their robust construction and wear-resistant components. Applicable industries span petrochemical (protecting large-scale steel structures from aggressive chemicals and harsh weather), metallurgy (applying uniform, protective coatings to fabricated metal parts), and water supply/drainage (ensuring the internal and external anti-corrosion treatment of pipes and tanks). In typical application scenarios, such as our Steel Structure Automatic Painting Line, these machines demonstrate significant advantages by reducing paint consumption through optimized spray trajectories, leading to considerable energy savings. Moreover, the consistent and thick protective layer applied by the automated painting process significantly enhances anti-corrosion properties, prolonging the lifespan of infrastructure and industrial assets.

Key Technical Specifications and Performance Metrics

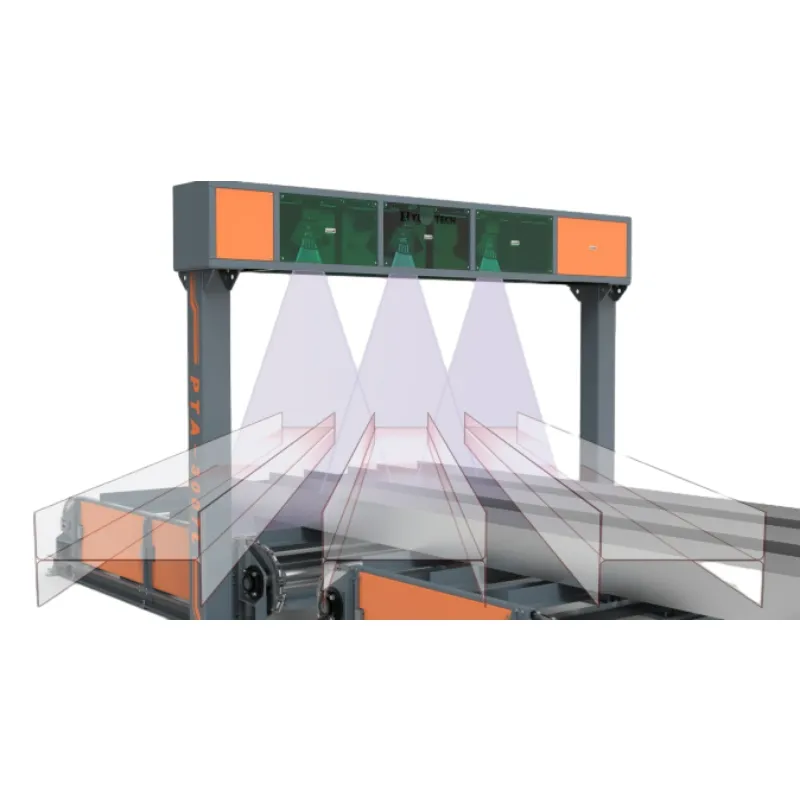

Understanding the technical specifications of an automatic paint spraying machine is crucial for evaluating its suitability for specific industrial applications and achieving optimal results. These machines are designed to operate within precise parameters, ensuring efficiency, consistency, and a high-quality finish. Key specifications typically include the operating pressure range, which dictates the force of paint atomization and transfer efficiency; flow rate, indicating how much paint can be applied per unit of time; and power consumption, an important factor for operational cost analysis. The spray pattern width and adjustability determine the coverage area and adaptability to various part geometries. At the core of every advanced system is a sophisticated control unit, often a Programmable Logic Controller (PLC) from leading manufacturers like Siemens or Allen-Bradley, which manages multi-axis robotic movements, precise paint dispensing, and curing parameters. The number of axes (e.g., 6-axis robotic arms) defines the machine’s flexibility and reach, allowing for complex geometries to be coated uniformly. Integrated curing options, such as Infrared (IR) or Ultraviolet (UV) lamps, significantly accelerate drying times and enhance coating properties. Material compatibility is paramount, as a versatile automatic paint dispenser must handle a wide range of coatings, from primers and topcoats to specialized anti-corrosion or fire-retardant paints, including solvent-based, water-based, and powder coatings, often with automated viscosity control.

| Parameter | Value/Range | Benefit to User |

|---|---|---|

| Operating Pressure Range | 50-250 Bar (725-3625 PSI) | Versatility for various paint viscosities; optimal atomization for fine finish. |

| Max Paint Flow Rate | Up to 5 L/min | High throughput for large surface areas; reduced cycle times. |

| Robotic Axes | 6-Axis Articulated Robot | Exceptional flexibility; access to complex part geometries; consistent angle. |

| Control System | Industrial PLC (Siemens S7/Allen-Bradley) | Precise control; easy integration with factory automation; reliable operation. |

| Transfer Efficiency | 70-90% (electrostatic modes) | Significant paint savings; reduced waste and VOC emissions. |

| Power Consumption | 15-30 kW (typical for full line) | Optimized energy use for cost-effective operation. |

| Paint Compatibility | Solvent-based, Water-based, 2K, Powder, UV-cure | Broad application range; flexibility for various industrial coatings. |

These detailed parameters highlight how an automatic paint spraying machine translates into practical advantages like high transfer efficiency (reducing overspray and material waste), rapid cycle times, and exceptionally uniform coat thicknesses. Compared to manual painting, which is prone to inconsistencies and higher material consumption, or less advanced automated painting process systems lacking multi-axis precision, a modern automatic spray painting system significantly boosts productivity and finish quality, directly impacting a product's market value and operational cost. The integrated control systems allow for precise adjustments and repeatable performance, ensuring that every product meets the most stringent quality specifications without fail.

Versatile Applications and Transformative Industry Impact

The adaptability and precision of an automatic paint spraying machine enable its deployment across a vast spectrum of industrial sectors, each benefiting from the enhanced efficiency and superior finish quality. In the construction and infrastructure industry, these machines are indispensable for coating large steel structures, such as bridges, building frameworks, and railway components, providing critical protection against corrosion and environmental degradation. The automotive sector utilizes automatic paint dispensers for applying flawless finishes to vehicle bodies, chassis, and individual parts, where aesthetic perfection and long-term durability are paramount. In the heavy machinery domain, from agricultural equipment to mining vehicles, the automated painting process ensures robust, weather-resistant coatings that withstand harsh operating conditions. Furniture manufacturers leverage these systems for uniform application of lacquers and stains, achieving high-volume production with consistent artistic quality. Even in the electronics industry, specialized coatings for components or enclosures are applied with unparalleled precision by an automatic spray painting system. The economic benefits are substantial: significantly reduced labor costs due to automation, faster throughput leading to increased production capacity, and minimized rework rates due to consistent quality. Environmentally, the technology contributes to lower Volatile Organic Compound (VOC) emissions through higher transfer efficiency and optimized paint usage, aligning with global sustainability goals. For instance, industries requiring specific anti-corrosion treatments, fire-resistant coatings, or specialized aesthetic finishes find the precise control offered by these machines to be invaluable. The ability to program complex spray paths and adjust parameters in real-time ensures that even the most challenging coating requirements are met with precision, solidifying the role of automated paint spraying in modern manufacturing.

Technological Superiority and Tailored Solutions

The technological edge of a modern automatic paint spraying machine lies in its integration of advanced features that push the boundaries of industrial coating. Innovations like intelligent sensor integration enable real-time detection of part geometry and surface irregularities, allowing for adaptive painting programs that optimize coverage and minimize waste. AI-driven adaptive painting algorithms can learn from previous runs, continuously refining spray paths and parameters for unparalleled efficiency and quality. Features such as self-cleaning nozzles reduce downtime and maintenance, ensuring continuous operation. Quick color change systems, often involving automated flushing and modular design, facilitate rapid transitions between different paint types and colors, a critical advantage in multi-product manufacturing environments. These technological advancements collectively contribute to superior finish quality, characterized by uniform thickness, excellent adhesion, and consistent appearance, while also significantly boosting operational efficiency through reduced material consumption and faster cycle times. Beyond standard models, leading manufacturers specialize in providing comprehensive customization options to meet unique production line challenges and specific coating requirements. This includes specialized robotic arms with extended reach or multi-axis motion for highly complex parts, integrated drying tunnels (e.g., convection or IR/UV curing) for accelerated processing, and bespoke material handling systems that seamlessly integrate the painting process into existing manufacturing workflows. Whether it's a need for handling extremely large components, applying highly specialized protective coatings, or integrating with existing robotics infrastructure, a tailored automatic spray painting system ensures optimal performance and a precise fit for any industrial context.

Choosing the Right Partner: Manufacturer Comparison and Project Delivery

Selecting the ideal manufacturer for your automatic paint spraying machine is as critical as the technology itself. Leading providers distinguish themselves not only through innovative product design but also through their commitment to research and development, comprehensive after-sales support, and robust global service networks. A manufacturer's R&D investment signals their dedication to pushing technological boundaries, developing more efficient and intelligent solutions. Crucially, post-installation support, including maintenance services, spare parts availability, and remote diagnostics, ensures minimal downtime and sustained operational efficiency. Reputable companies often possess certifications like ISO 9001 for quality management and CE marking for product safety, underscoring their adherence to international standards and their authority in the field. Our company, with over 20 years of experience in developing and deploying advanced industrial coating solutions, has a proven track record exemplified by long-standing partnerships with major players in industries such as energy, infrastructure, and heavy manufacturing. We pride ourselves on offering a seamless project lifecycle, commencing with in-depth consultation and site assessment to meticulously understand client needs and production line specifics. This leads to tailored system design, meticulous engineering, precise manufacturing, and professional installation. Post-installation, comprehensive commissioning ensures optimal performance, followed by thorough operator training to maximize system utilization and efficiency. Our commitment extends to delivering solutions like the Steel Structure Automatic Painting Line, which represents a significant investment and partnership, designed to provide long-term reliability and measurable ROI. Our authoritative position in the market is reinforced by a portfolio of successful installations and client testimonials, along with rigorous internal testing data that consistently demonstrates the superior performance and durability of our automatic spray painting system products.

Transformative Impact: Case Studies and Client Success

The real-world application of an automatic paint spraying machine consistently demonstrates its transformative impact on industrial operations. Consider a recent success story from a prominent steel fabrication company specializing in large-scale structural components for commercial buildings. Facing escalating labor costs, inconsistent coating quality, and significant paint material waste, they sought an advanced automated solution. By implementing our Steel Structure Automatic Painting Line, equipped with a multi-axis robotic automatic paint dispenser and integrated curing, the client achieved remarkable improvements. Within six months of operation, they reported a verified 30% reduction in paint consumption, primarily due to the system's superior transfer efficiency and precise application, which significantly minimized overspray. Concurrently, throughput increased by an astounding 40%, allowing them to take on more projects and meet tighter deadlines without expanding their physical footprint. The consistency of the automated painting process eliminated rework due to uneven coating, leading to a noticeable improvement in overall product quality and customer satisfaction. The production manager remarked, "Our investment in this automatic spray painting system has not only revolutionized our coating process but has directly impacted our bottom line and enhanced our reputation for quality. The support from the manufacturer throughout installation and commissioning was exceptional." This case exemplifies how a well-integrated automatic painting solution can drive operational excellence, deliver substantial cost savings, and elevate product standards, providing a compelling return on investment and a competitive edge in a demanding market.

Ensuring Trust: FAQ, Delivery, and Warranty Commitments

Building trust with B2B clients requires transparency and a robust support infrastructure. We address common inquiries and provide clear commitments regarding product delivery, warranty, and ongoing customer support for our automatic paint spraying machine solutions.

Frequently Asked Questions (FAQ)

- Q: What types of paints can your automatic paint dispenser handle?

A: Our systems are engineered for versatility, capable of applying a wide range of industrial coatings including solvent-based, water-based, two-component (2K) paints, primers, topcoats, special anti-corrosion paints, and some powder coatings. Compatibility is fine-tuned during the consultation phase based on your specific needs. - Q: What is the typical Return on Investment (ROI) for an automated painting process?

A: While specific ROI varies by application, clients typically see significant returns within 1-3 years due to reduced labor costs, substantial material savings (often 20-40% less paint consumption), increased throughput, and fewer reworks due to consistent quality. - Q: How often does an automatic spray painting system require maintenance?

A: Our machines are designed for high reliability and low maintenance. Routine preventive maintenance, typically scheduled quarterly or semi-annually depending on usage, involves checking fluid lines, nozzles, and robotic components. Our technical team provides detailed maintenance schedules and training.

Delivery and Installation

Our typical delivery period for a complete automatic paint spraying machine or Steel Structure Automatic Painting Line ranges from 8 to 16 weeks, depending on the system's complexity and customization requirements. This timeframe includes design, manufacturing, factory testing, and shipment. Prior to installation, a comprehensive site assessment is conducted to ensure seamless integration into your facility. Our certified engineers oversee the entire installation process, ensuring compliance with all safety and operational standards. Post-installation, rigorous commissioning is performed to optimize system performance, followed by on-site training for your operational and maintenance teams, empowering them with the knowledge to efficiently manage the new automated system.

Warranty and Customer Support

We stand by the quality and durability of our products with a comprehensive warranty. All major components of our automatic paint spraying machine are covered by a 12-month warranty from the date of installation or 18 months from shipment, whichever comes first. This warranty covers manufacturing defects and ensures the reliable performance of the equipment. Beyond the warranty period, we offer flexible service contracts and guarantee prompt availability of spare parts, minimizing potential downtime. Our dedicated customer support team provides 24/7 technical assistance, including remote diagnostics and troubleshooting, to address any operational queries or issues swiftly. This commitment to ongoing support underscores our partnership approach, ensuring your investment continues to yield maximum productivity and efficiency for years to come.

The Future of Industrial Coating is Automated

The continuous evolution of the automatic paint spraying machine solidifies its position as an indispensable asset for modern industrial manufacturing. Far more than just a piece of equipment, it represents a strategic investment in precision, efficiency, and sustainability. By embracing an automated painting process, businesses can achieve unparalleled coating quality, significantly reduce operational costs through optimized material usage and reduced labor requirements, and enhance workplace safety by minimizing human exposure to hazardous environments. The ability of an advanced automatic paint dispenser to consistently deliver uniform finishes, even on complex geometries, ensures that products not only look superior but also gain enhanced durability and protection against corrosion and wear. As industries continue to face pressures for higher output, lower environmental impact, and consistent quality, the adoption of a sophisticated automatic spray painting system will be a key differentiator. It is a commitment to technological leadership, operational excellence, and a future where every surface is finished to perfection. The strategic integration of these systems positions manufacturers to meet current demands while adapting to future market challenges and opportunities with agility and confidence.

References

- Smith, J. A. (2022). "Robotics in Surface Coating: A Review of Automated Spraying Technologies." Journal of Manufacturing Automation, 15(3), 123-135.

- Chen, L., & Wang, Q. (2021). "Optimization of Paint Transfer Efficiency in Electrostatic Spraying Processes." International Journal of Industrial Coatings, 8(2), 78-91.

- Global Market Insights. (2023). "Industrial Coatings Market Size, Share & Trends Analysis Report."

Products Categories

Latest News

-

Unveiling the World of Container Handling Equipment in the Marketplace

NewsAug.27,2025 -

Unlocking the Potential of Container Lifting Equipment

NewsAug.27,2025 -

Essential Equipment in Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Efficient Solutions for Shipping Container Manipulation

NewsAug.27,2025 -

Efficient Solutions for Container Handling: Equipment Insights

NewsAug.27,2025 -

Efficient Solutions for Container Handling: A Comprehensive Overview

NewsAug.27,2025 -

Welding Fume Composition Analysis

NewsAug.26,2025