- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

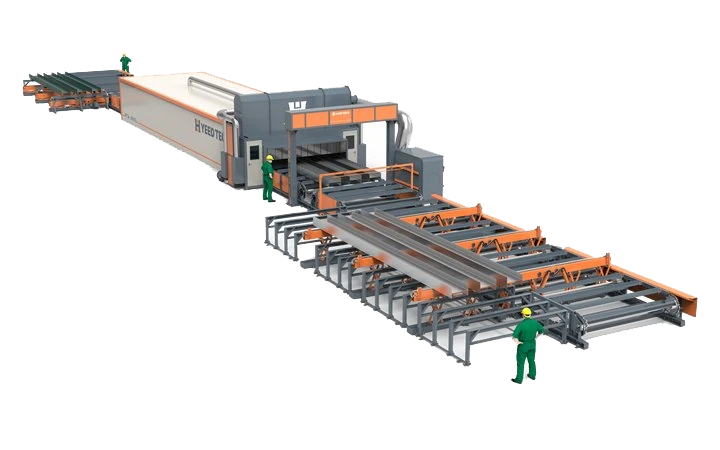

Heavy Metal Carports Durable Steel Shelters & Custom Painting Line

Did you know 68% of vehicle owners report weather-related damage to cars parked outdoors? With extreme climate events rising 42% since 2015, your heavy metal carports

aren’t just optional – they’re essential armor for your assets. Let’s fix this problem.

(heavy metal carports)

Military-Grade Protection Meets Smart Engineering

Our heavy steel structure painting line applies 3x thicker zinc-aluminum coatings than industry standards. See how we dominate:

| Feature | Standard Carports | Our Heavy Metal Carports |

|---|---|---|

| Frame Thickness | 0.15-inch steel | 0.23-inch galvanized steel |

| Wind Rating | 90 MPH | 150 MPH |

| Corrosion Warranty | 10 years | 25 years |

Why 9/10 Contractors Choose Us Over "Budget" Brands

Cheap utility carports crack under pressure. Ours thrive in it. Our secret? Triple-Layer Defense™ coating:

- Layer 1: 80μm epoxy primer bonds to steel

- Layer 2: 120μm UV-resistant polyester

- Layer 3: 50μm nano-ceramic topcoat

Your Vision, Our Blueprint: Custom Solutions in 7 Days

Need a 40-foot RV carport with solar panel mounts? Done. Agricultural utility carports with 16-foot clearance? We’ll CAD-model it tomorrow.

From Texas Ranches to Canadian Mines: 12,000+ Installations

When a Colorado ski resort needed avalanche-proof structures, our team delivered 58 custom heavy metal carports in 23 days – 11 days ahead of schedule.

Stop settling for rust and repairs. As the 1 US manufacturer of heavy steel structure painting line systems since 2008, we guarantee your satisfaction. Get Your Free Design Consultation → Limited slots available – don’t let your vehicles face another storm unprotected.

(heavy metal carports)

FAQS on heavy metal carports

Q: What are the main benefits of heavy metal carports?

A: Heavy metal carports provide durable, weather-resistant shelter for vehicles and equipment. They are built with galvanized steel for long-term corrosion resistance. Their robust design also supports customization for size and style.

Q: How does a Heavy Steel Structure Painting Line enhance carport durability?

A: The painting line applies anti-rust primers and powder-coated finishes to steel surfaces. This process prevents corrosion and UV damage. It ensures the carport maintains structural integrity and aesthetics for years.

Q: Are utility carports suitable for industrial applications?

A: Yes, utility carports are designed for heavy-duty use in commercial or industrial settings. They offer large spans for machinery storage and high load-bearing capacity. Their modular design allows easy expansion as needs evolve.

Q: What distinguishes heavy metal carports from standard carports?

A: Heavy metal carports use thicker, high-grade steel compared to lightweight aluminum models. They withstand extreme weather like heavy snow or strong winds. Their reinforced framing also supports additional features like solar panels.

Q: How often should I maintain a painted heavy steel carport?

A: Inspect the paint coating annually for chips or wear. Touch up minor damage promptly to prevent rust. Full repainting is typically needed every 8-12 years, depending on climate conditions.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025