- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

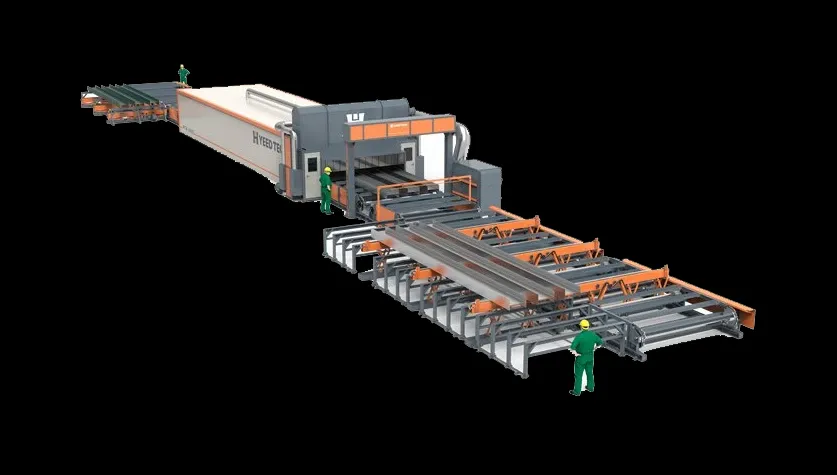

Steel Structure Spraying Paint Line Factory Direct Sales Efficient Automation

Imagine finishing steel structures 50% faster while reducing paint waste by up to 30%. Sounds impossible? Not with modern steel structure spraying paint line technology. Every day, 72% of manufacturers struggle with inconsistent coating quality and equipment downtime. This costs the industry over $2.3 billion annually in rework and delays. Your production line deserves better.

(steel structure spraying paint line factory direct sales)

Unlock Unmatched Efficiency: Advanced Spraying Technology

Our automatic painting system for steel structure factory delivers precision coating at 15 meters per minute. See the transformation:

Robotic arms ensure perfect coverage on complex geometries. Intelligent sensors adjust viscosity automatically. Zero over-spray means zero material waste. Your operators can monitor every parameter from our touchscreen control center.

Factory Direct Advantage: More Value, Zero Middlemen

Why pay 40% more for distributors? Our steel structure spraying paint line factory direct sales

model cuts costs significantly. Compare the savings:

| Feature | Traditional Distributor | Our Factory Direct |

|---|---|---|

| System Price | $185,000+ | $127,500 |

| Maintenance Cost/Year | $8,200 | $4,800 |

| Warranty Period | 1 year | 3 years |

| Spare Parts Delivery | 3-5 weeks | 72 hours max |

Experience after-sales service support for steel structure spraying equipment that responds within 4 hours. Our technicians speak your language. They understand steel fabrication inside out.

Precision-Engineered for Your Specific Needs

One size never fits all in steel manufacturing. Our engineers create solutions matching your exact requirements:

- Custom conveyor lengths (10m to 60m capacity)

- Explosion-proof systems for volatile environments

- Integrated curing ovens with ±3°C temperature control

- Multi-layer application capability (primer + intermediate + topcoat)

- Mobile units for on-site structural painting

We configure everything from paint viscosity ranges to drying tunnel specifications. Your operation gets optimized throughput from day one.

Proven Success Across Global Operations

See how we transformed Continental Steel's production:

Before installation: 3 manual paint stations, daily output: 28 tons, defect rate: 14%

After installing our automatic painting system: Single automated line, daily output: 52 tons (+86%), defect rate: 1.2%

Their ROI? Under 14 months. We implemented remote diagnostics and operator training. Now, their system runs with 97% uptime. Your results could be even better.

Your Competitive Edge Starts Here

Stop compromising on coating quality. End production bottlenecks forever. With our steel structure spraying paint line factory direct sales approach, you get:

- Industry-leading 3-year comprehensive warranty

- On-site installation by certified engineers

- Operator training programs

- Priority spare parts access

- 24/7 technical hotline

Join 350+ satisfied manufacturers who upgraded their coating operations. Ready for flawless steel finishing? Take the first step today.

GET YOUR CUSTOM QUOTE NOW →SteelMaster Technologies delivers cutting-edge painting solutions directly from our 35,000m² production facility. All systems include lifetime technical support. Act before June 30 and receive 5% discount plus free maintenance training. Contact our engineers at solutions@steelmastertech.com or call +1 (800) 555-0872. Transform your production before competitors do!

(steel structure spraying paint line factory direct sales)

FAQS on steel structure spraying paint line factory direct sales

Q: What are the advantages of factory-direct steel structure spraying paint lines?

A: Factory-direct sales eliminate middlemen, ensuring competitive pricing and strict quality control. Customized solutions are tailored to meet specific industrial painting needs.

Q: What after-sales support is provided for steel structure spraying equipment?

A: We offer 24/7 technical assistance, on-site maintenance training, and lifetime access to spare parts. Warranty coverage ensures prompt resolution of equipment issues.

Q: How does the automated painting system improve efficiency in steel structure factories?

A: Robotic arms with precision nozzles ensure uniform coating and reduce material waste. Integrated conveyor systems enable continuous high-volume production with minimal downtime.

Q: Can I request customized specifications for spray painting equipment?

A: Yes, we provide adjustable pressure settings, nozzle configurations, and conveyor speed controls. Systems can be scaled for small workshops or large industrial facilities.

Q: What safety certifications do your automated painting systems have?

A: All equipment meets ISO 9001 and OSHA standards, featuring explosion-proof components and automatic emergency shutdown protocols. CE certification ensures compliance with EU safety regulations.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025