- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

មករា . 14, 2025 09:34

Back To List

container lifting machine

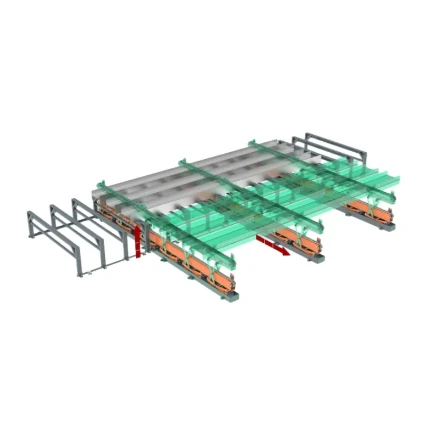

The advent of automated spray line technology has revolutionized various industries, especially those that rely on precision coating and efficient production processes. These innovative systems are more than just a modern convenience; they are a transformative solution that integrates cutting-edge automation with superior engineering practices.

Trust in automated spray lines also stems from their commitment to safety and sustainability. Advanced models are designed with integrated ventilation and filtering systems that capture volatile compounds, protecting employees from harmful exposure and reducing environmental impact. Additionally, many systems comply with rigorous industry standards for emissions, offering peace of mind to companies striving to meet their corporate social responsibility goals. From an operational standpoint, the ease of maintenance further enhances the reliability of automated spray lines. Regular upkeep is simplified through predictive diagnostics, which alert operators to potential issues before they lead to downtime. This proactive approach not only prolongs the lifespan of the equipment but also results in cost efficiencies by preventing unexpected repairs. Businesses considering investment in automated spray lines should leverage insights from seasoned professionals who have successfully navigated this transition. Peer-reviewed case studies and testimonials serve as valuable resources, offering practical advice and highlighting common challenges to anticipate. Furthermore, partnerships with reputable manufacturers provide access to training programs and technical support, ensuring that staff are well-equipped to operate and maintain the new systems effectively. In summary, the implementation of an automated spray line is not merely an upgrade to existing processes; it represents a strategic advancement in manufacturing efficiency and quality assurance. As a testament to their transformative impact, these systems are increasingly becoming the industry standard, setting benchmarks for innovation and excellence across diverse sectors.

Trust in automated spray lines also stems from their commitment to safety and sustainability. Advanced models are designed with integrated ventilation and filtering systems that capture volatile compounds, protecting employees from harmful exposure and reducing environmental impact. Additionally, many systems comply with rigorous industry standards for emissions, offering peace of mind to companies striving to meet their corporate social responsibility goals. From an operational standpoint, the ease of maintenance further enhances the reliability of automated spray lines. Regular upkeep is simplified through predictive diagnostics, which alert operators to potential issues before they lead to downtime. This proactive approach not only prolongs the lifespan of the equipment but also results in cost efficiencies by preventing unexpected repairs. Businesses considering investment in automated spray lines should leverage insights from seasoned professionals who have successfully navigated this transition. Peer-reviewed case studies and testimonials serve as valuable resources, offering practical advice and highlighting common challenges to anticipate. Furthermore, partnerships with reputable manufacturers provide access to training programs and technical support, ensuring that staff are well-equipped to operate and maintain the new systems effectively. In summary, the implementation of an automated spray line is not merely an upgrade to existing processes; it represents a strategic advancement in manufacturing efficiency and quality assurance. As a testament to their transformative impact, these systems are increasingly becoming the industry standard, setting benchmarks for innovation and excellence across diverse sectors.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025