- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

មករា . 13, 2025 17:07

Back To List

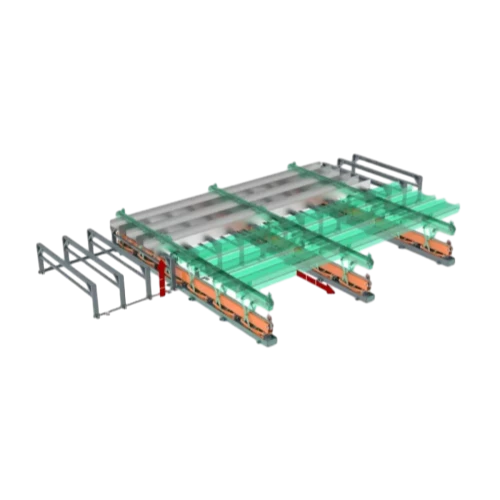

Container Lifting Jacks

Automated spray painting machines have revolutionized the way industries approach painting, offering unmatched precision, efficiency, and consistency. These machines, designed to deliver seamless finishes, are increasingly becoming vital assets in fields ranging from automotive to furniture manufacturing. Their integration into production lines not only enhances productivity but also ensures that quality remains uncompromised.

Trustworthiness and reliability in a manufacturing setting are enhanced through automated spray painting machines. Consistency in quality output builds customer confidence, essential for brands looking to establish or maintain a strong market presence. Being able to guarantee that each product meets high standards without variation is invaluable, particularly in industries where precision and quality are non-negotiable. Incorporating automated spray painting technology results in not just operational advantages but also bolsters a company’s position as a leader in innovation. By demonstrating a commitment to advanced, efficient manufacturing processes, companies can attract discerning clients who value precision and quality. Furthermore, the long-term cost savings and environmental benefits establish companies as pioneers in adopting sustainable and forward-thinking solutions. In conclusion, automated spray painting machines are more than an industrial convenience; they are a strategic asset that empower companies to deliver superior products while enhancing operational efficiency. Their integration into production processes echoes a commitment to quality, safety, and environmental stewardship. For businesses aiming to set themselves apart, investing in automated spray technology is a testament to their dedication to excellence and innovation.

Trustworthiness and reliability in a manufacturing setting are enhanced through automated spray painting machines. Consistency in quality output builds customer confidence, essential for brands looking to establish or maintain a strong market presence. Being able to guarantee that each product meets high standards without variation is invaluable, particularly in industries where precision and quality are non-negotiable. Incorporating automated spray painting technology results in not just operational advantages but also bolsters a company’s position as a leader in innovation. By demonstrating a commitment to advanced, efficient manufacturing processes, companies can attract discerning clients who value precision and quality. Furthermore, the long-term cost savings and environmental benefits establish companies as pioneers in adopting sustainable and forward-thinking solutions. In conclusion, automated spray painting machines are more than an industrial convenience; they are a strategic asset that empower companies to deliver superior products while enhancing operational efficiency. Their integration into production processes echoes a commitment to quality, safety, and environmental stewardship. For businesses aiming to set themselves apart, investing in automated spray technology is a testament to their dedication to excellence and innovation.

Prev:

Next:

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025