- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Feb . 14, 2025 16:52

Back To List

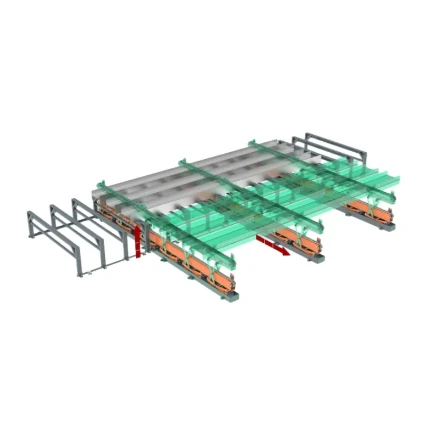

sistema de manipulación de contenedores

The global shipping industry has experienced revolutionary strides in recent years, paving the path for advanced systems that make the manipulation of containers more efficient and reliable. As enterprises seek to enhance operational competence, container handling systems emerge as pivotal elements comparable to precision instruments in a colossal machine. This exploration delves into the intricacies, technical prowess, and authoritative solutions that container handling systems offer, fueling industrial productivity.

Moreover, the design of these systems often includes features that accommodate various container types and sizes, combining flexibility with specialization. This adaptability ensures that diverse cargo types are handled efficiently, enabling companies to serve a broader range of clientele without compromising service quality. The expertise involved in developing and deploying container manipulation systems speaks volumes about their effectiveness. Leading manufacturers invest heavily in research and development to stay ahead of technology trends. Their dedication translates into systems that set industry standards, highlighting an authoritative approach in their design and deployment. What sets these systems apart is their emphasis on sustainability. Many solutions are designed with eco-friendly practices, utilizing energy-efficient technologies that decrease the carbon footprint of shipping operations. This not only aligns with global sustainability initiatives but also demonstrates the system's adaptability to evolving environmental regulations. The financial implication of adopting cutting-edge container handling systems is offset by the resultant gains in efficiency and throughput. Long-term savings through reduced labor costs, minimized delays, and enhanced container tracking feature prominently in the cost-benefit analysis, justifying the initial capital expenditure. In summary, container handling systems represent the summit of technological and operational finesse in the logistics domain. Their ability to marry mechanization with digital intelligence characterizes them as indispensable assets in container terminals worldwide. Through responsiveness, reliability, and sustainability, these systems provide a competitive edge that underscores trust and authority in global shipping operations. Embracing such cutting-edge solutions enables companies to not only meet present-day demands but to also chart new courses in the global supply chain landscape.

Moreover, the design of these systems often includes features that accommodate various container types and sizes, combining flexibility with specialization. This adaptability ensures that diverse cargo types are handled efficiently, enabling companies to serve a broader range of clientele without compromising service quality. The expertise involved in developing and deploying container manipulation systems speaks volumes about their effectiveness. Leading manufacturers invest heavily in research and development to stay ahead of technology trends. Their dedication translates into systems that set industry standards, highlighting an authoritative approach in their design and deployment. What sets these systems apart is their emphasis on sustainability. Many solutions are designed with eco-friendly practices, utilizing energy-efficient technologies that decrease the carbon footprint of shipping operations. This not only aligns with global sustainability initiatives but also demonstrates the system's adaptability to evolving environmental regulations. The financial implication of adopting cutting-edge container handling systems is offset by the resultant gains in efficiency and throughput. Long-term savings through reduced labor costs, minimized delays, and enhanced container tracking feature prominently in the cost-benefit analysis, justifying the initial capital expenditure. In summary, container handling systems represent the summit of technological and operational finesse in the logistics domain. Their ability to marry mechanization with digital intelligence characterizes them as indispensable assets in container terminals worldwide. Through responsiveness, reliability, and sustainability, these systems provide a competitive edge that underscores trust and authority in global shipping operations. Embracing such cutting-edge solutions enables companies to not only meet present-day demands but to also chart new courses in the global supply chain landscape.

Prev:

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025